Asphalt pavement maintenance agent and its preparation method and application

A technology of asphalt pavement and curing agent, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of pavement damage, short service life of asphalt pavement, water seepage, etc., and achieve simple and convenient construction technology, strong environmental adaptability, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Example 1: A pavement maintenance agent in asphalt, including component A and component B, which are independent of each other. The component A includes the following components by weight: 7 parts of petroleum asphalt, 10 parts of cashew nut shell liquid modified amine, 1 1 part rare earth, 1 part asphalt regenerant, 1 part anti-aging agent, 10 parts PTFE emulsion, 1 part carbon black, 10 parts calcined kaolin;

[0036]Among them, the solid content of the polytetrafluoroethylene emulsion is 65%, the particle size of the emulsion is 2000nm, and the relative density is 1.55. The cashew nut shell liquid modified amine is a natural long-chain substituted phenalkamine prepared by the reaction of cashew nut oil, formaldehyde, and polyamines. Hardener;

[0037]Among them, the asphalt regenerant is synthetic rubber extender oil and activated rubber powder with a mass ratio of 1:1;

[0038]B includes the following components by weight: 1 part of styrene, 10 parts of ammonium persulfate aqueous ...

Embodiment 2-5

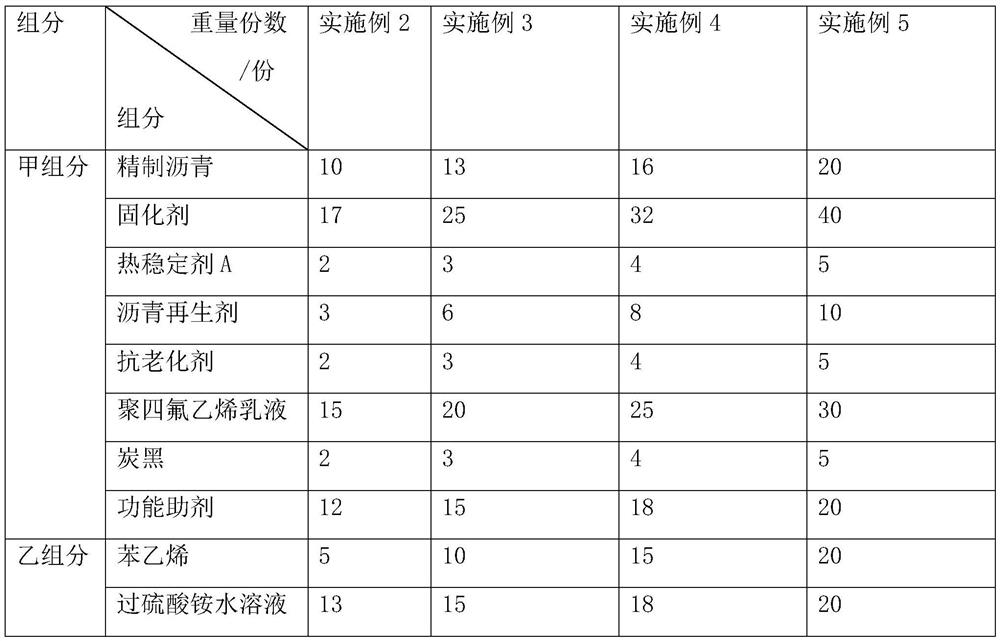

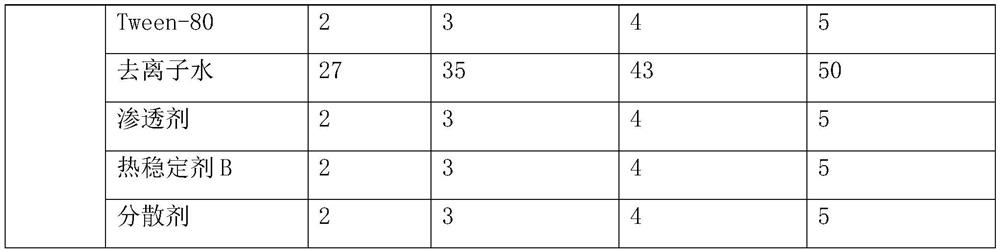

[0043]Example 2-5: An asphalt pavement maintenance agent. The difference from Example 1 is that the parts by weight of the components in the first and second components are different, and the parts by weight of the components in the first and second components are different The numbers are shown in Table 1.

[0044]

[0045]

[0046]Among them, the refined asphalt in Example 2 is coal tar pitch, the functional auxiliary agent is black placer, and the dispersant is methylpentanol; the refined asphalt in Example 3 is SBS thermoplastic styrene butadiene rubber modified asphalt, and the functional auxiliary agent is montmorillonite. , The dispersant is a cellulose derivative; the refined asphalt in Example 4 is a rubber powder modified asphalt, the functional auxiliary is calcium carbonate, and the dispersant is sodium lauryl sulfate; the functional auxiliary in Example 5 is carbon black.

Embodiment 6

[0047]Example 6: An asphalt pavement maintenance agent. The difference from Example 1 is that the regenerated asphalt agent is a synthetic rubber filler oil and activated rubber powder with a mass ratio of 1.5:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com