Method for preparing brandy by extracting aroma substances

A technology for aroma substances and brandy, applied in the field of brandy, can solve problems such as inability to extract useful substances in brandy, complicated operation, limited extraction effect, etc., and achieve the effects of reducing time cost and capital investment, improving quality, and shortening aging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

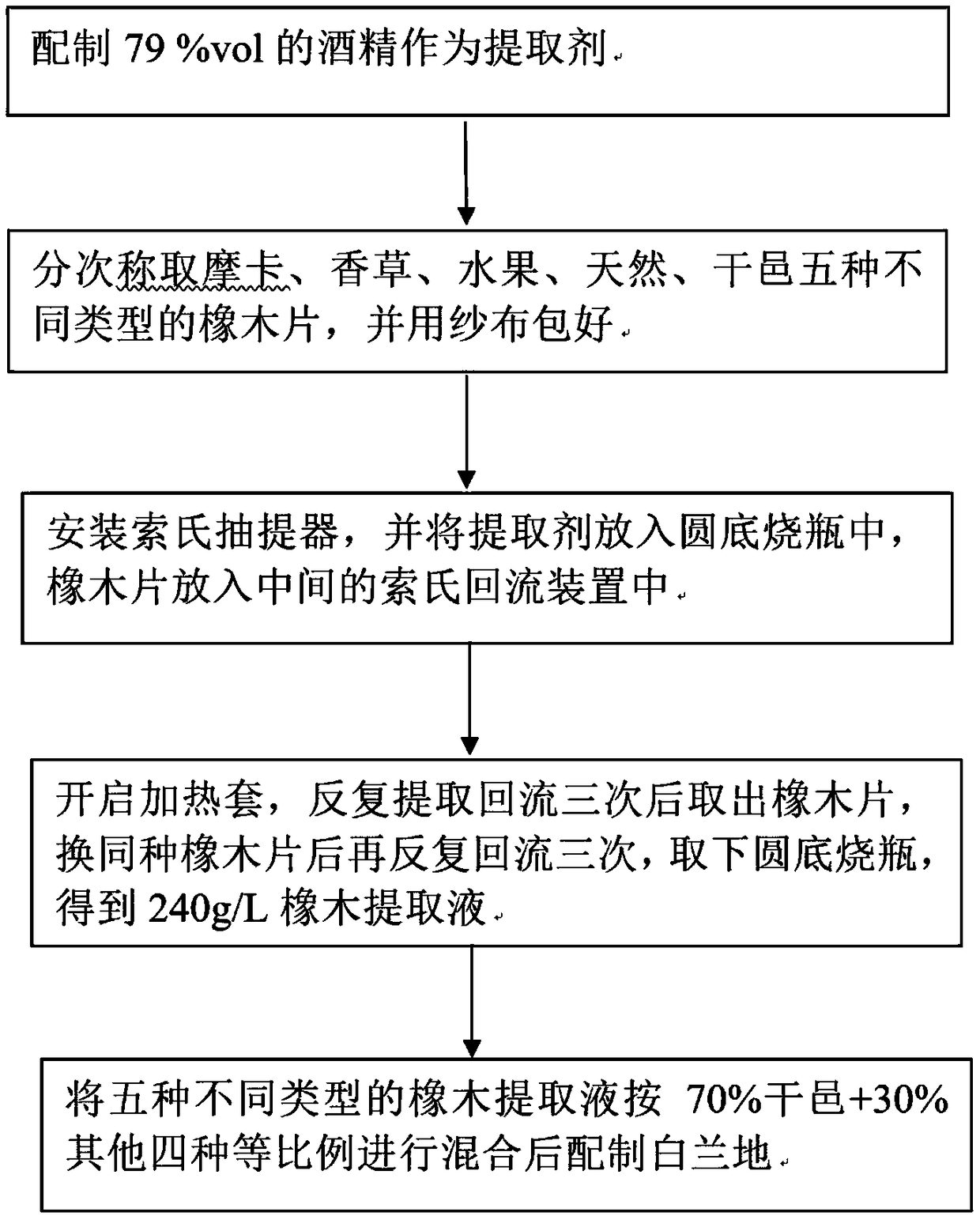

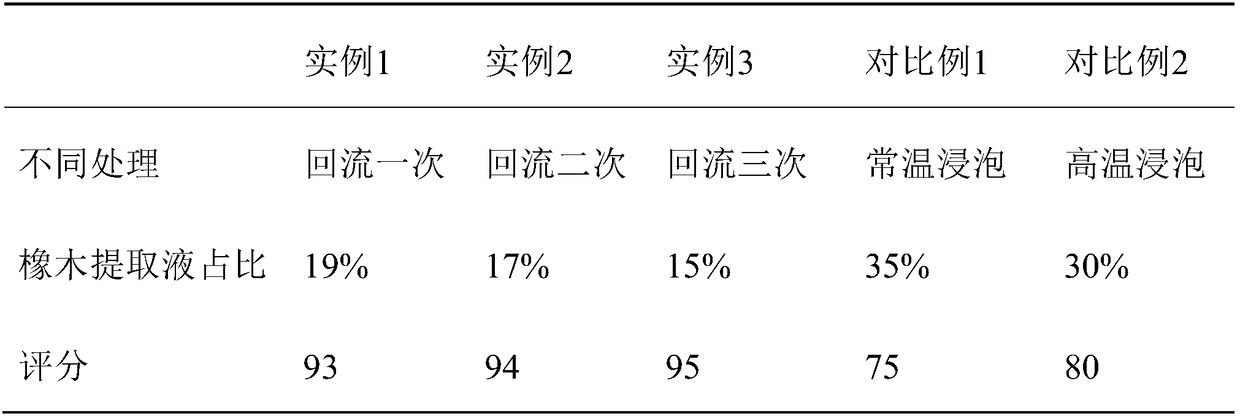

[0042] Embodiment 1 provides a method for extracting aroma substances for preparing brandy, reflux once.

[0043] S1: prepare 79% vol alcohol solution as extractant;

[0044] S2: Weigh 120g of five different types of oak chips from French medium toasted mocha, medium toasted vanilla, medium toasted fruit, lightly toasted natural, and heavy toasted cognac, and wrap them with gauze;

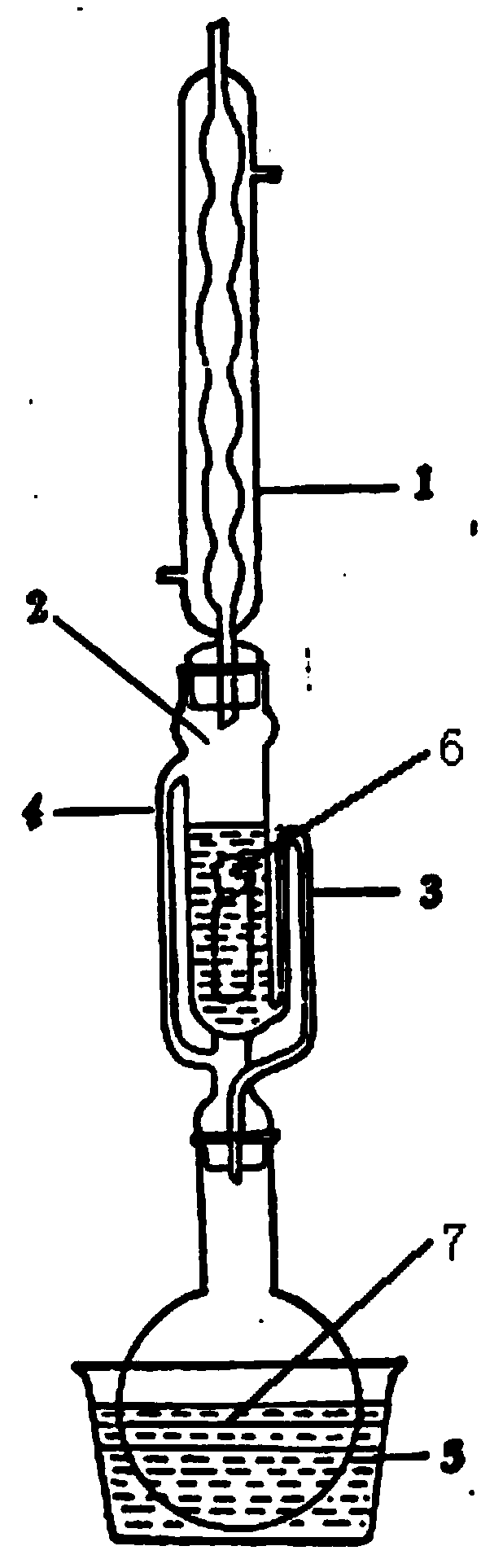

[0045] S3: Install 1L of Soxhlet extractor, put nearly 1L of extractant into a round bottom flask, and put 120g of oak chips into the middle Soxhlet reflux device;

[0046] S4: Turn on the heating mantle, take out the oak chips after extraction and reflux once, replace 120g of the same kind of oak chips, and then reflux once again, take off the round bottom flask, and obtain an oak extract with a concentration of 240g / L;

[0047] S5: Mix five different types of oak extracts in proportions of 70% cognac, 7.5% mocha, 7.5% vanilla, 7.5% fruit, and 7.5% natural.

Embodiment 2

[0049] Example 2 provides a method for extracting aroma substances for preparing brandy, which is refluxed twice.

[0050] S1: prepare 79% vol alcohol solution as extractant;

[0051] S2: Weigh 120g of five different types of oak chips from French medium toasted mocha, medium toasted vanilla, medium toasted fruit, lightly toasted natural, and heavy toasted cognac, and wrap them with gauze;

[0052] S3: Install 1L of Soxhlet extractor, put nearly 1L of extractant into a round bottom flask, and put 120g of oak chips into the middle Soxhlet reflux device;

[0053] S4: Turn on the heating mantle, take out the oak chips after extracting and refluxing twice, replace the same kind of oak chips with 120g, and then repeatedly reflux twice, take off the round-bottomed flask, and obtain an oak extract with a concentration of 240g / L;

[0054] S5: Mix five different types of oak extracts in proportions of 70% cognac, 7.5% mocha, 7.5% vanilla, 7.5% fruit, and 7.5% natural.

Embodiment 3

[0056] Example 3 provides a method for extracting aroma substances for preparing brandy, which is refluxed three times.

[0057]S1: prepare 79% vol alcohol solution as extractant;

[0058] S2: Weigh 120g of five different types of oak chips from French medium toasted mocha, medium toasted vanilla, medium toasted fruit, lightly toasted natural, and heavy toasted cognac, and wrap them with gauze;

[0059] S3: Install 1L of Soxhlet extractor, put nearly 1L of extractant into a round bottom flask, and put 120g of oak chips into the middle Soxhlet reflux device;

[0060] S4: Turn on the heating mantle, take out the oak chips after repeated extraction and reflux three times, replace the same kind of oak chips with 120 g, and then repeatedly reflux three times, take off the round bottom flask, and obtain an oak extract with a concentration of 240 g / L;

[0061] S5: Mix five different types of oak extracts in proportions of 70% cognac, 7.5% mocha, 7.5% vanilla, 7.5% fruit, and 7.5% na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com