A kind of treatment method of acidic bright tin plating solution

A technology of tin plating solution and treatment method, which is applied in the field of treatment of acidic bright tin plating solution, can solve the problems of limited adsorption capacity of activated carbon, waste of resources, increase of difficulty in filtration, etc., and achieve the effect of repeated recycling and reduction of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

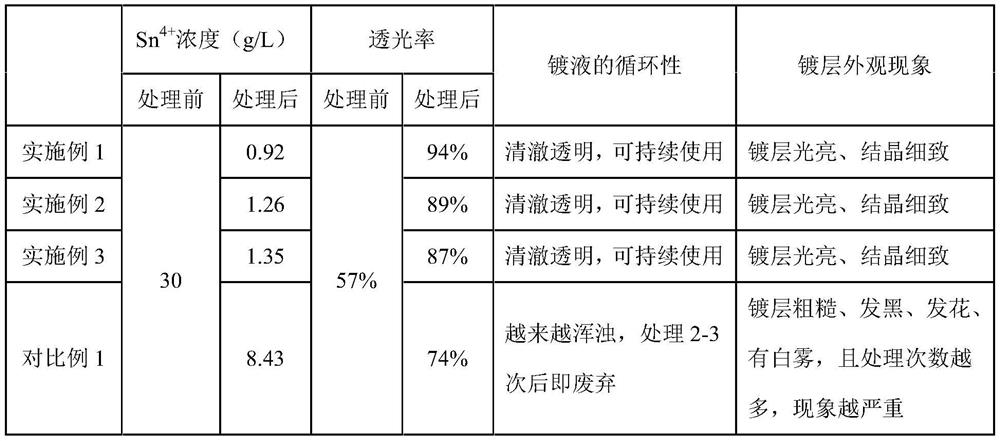

Embodiment 1

[0030] Take 1L of the plating solution to be treated, heat it to 75°C and keep it warm for 4 hours, cool naturally to 35°C, remove the upper layer of oil after layering, and slowly add 30ml SY-800 flocculant while stirring; continue to stir, add 3g of activated carbon, and let it stand After more than 24 hours, filter the supernatant to obtain the treated plating solution, and measure its Sn 4+ Concentration and light transmittance, the results are shown in Table 1.

[0031] Add additives such as brightener and stabilizer to the plating solution after the above treatment, and continue the electroplating reaction after electrolysis with a small current. Observe the coating of the plated parts, the results are shown in Table 1.

Embodiment 2

[0033] Take 1L of the plating solution to be treated, heat it to 70°C and keep it warm for 4 hours, cool it naturally to 30°C, remove the upper layer of oil after layering, and slowly add 40g of polyacrylamide flocculant while stirring; continue to stir, add 5g of activated carbon, and let it stand After more than 24 hours, filter the supernatant to obtain the treated plating solution, and measure its Sn 4+ Concentration and light transmittance, the results are shown in Table 1.

[0034] Add additives such as brightener and stabilizer to the plating solution after the above treatment, and continue the electroplating reaction after electrolysis with a small current. Observe the coating of the plated parts, the results are shown in Table 1.

Embodiment 3

[0036] Take 1L of the plating solution to be treated, heat it to 80°C and keep it warm for 4 hours, cool naturally to 40°C, remove the upper layer of oil after layering, and slowly add 20g of polyvinylamide flocculant while stirring; continue to stir, add 4g of activated carbon, and let it stand After more than 24 hours, filter the supernatant to obtain the treated plating solution, and measure its Sn 4+ Concentration and light transmittance, the results are shown in Table 1.

[0037] Add additives such as brightener and stabilizer to the plating solution after the above treatment, and continue the electroplating reaction after electrolysis with a small current. Observe the coating of the plated parts, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com