Adjusting device for engineering hydraulic support

A technology of hydraulic support and adjustment device, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of limiting construction efficiency, unable to adjust the pitch angle of hydraulic support, etc., and achieves simple operation, convenient adjustment and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

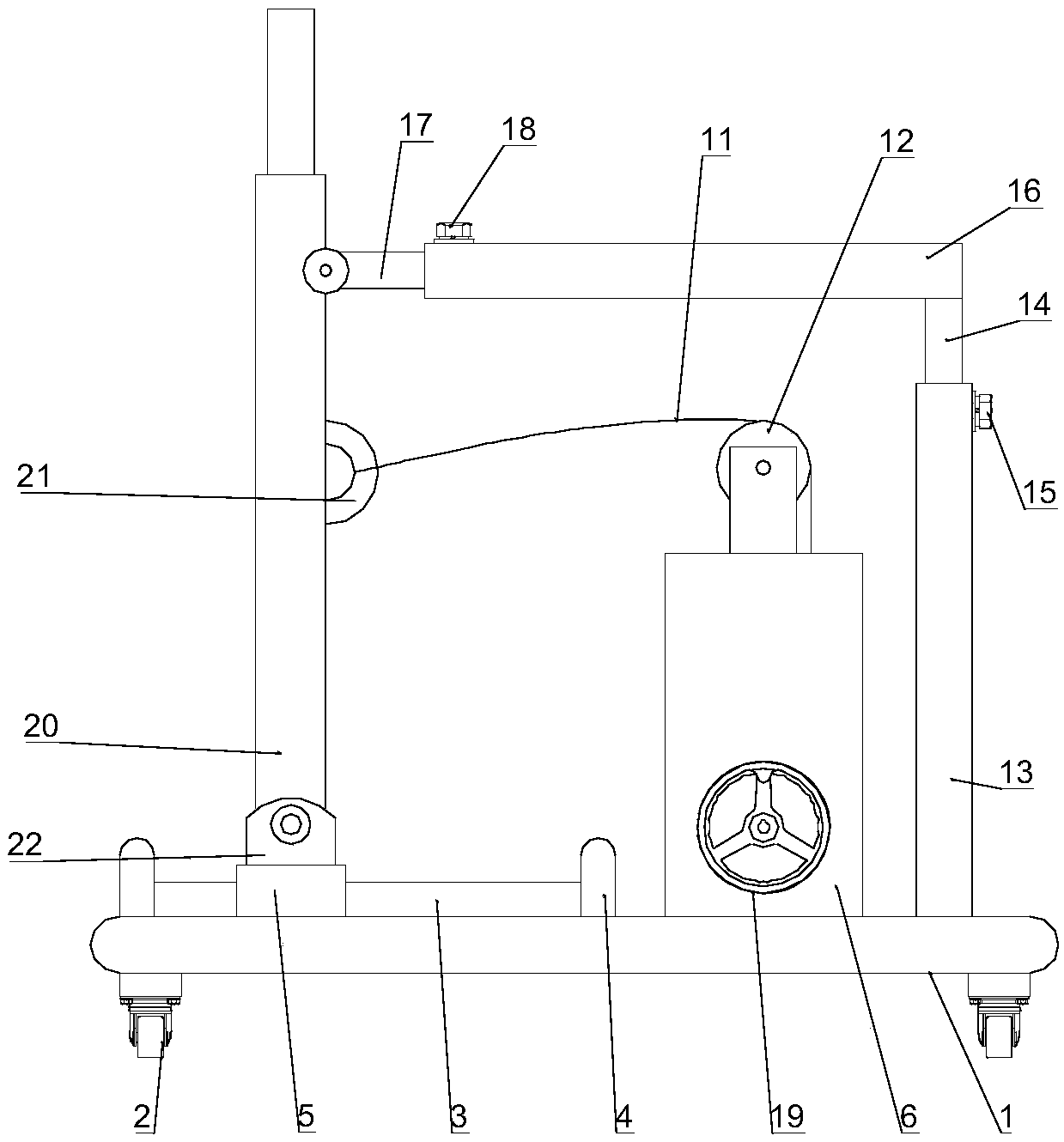

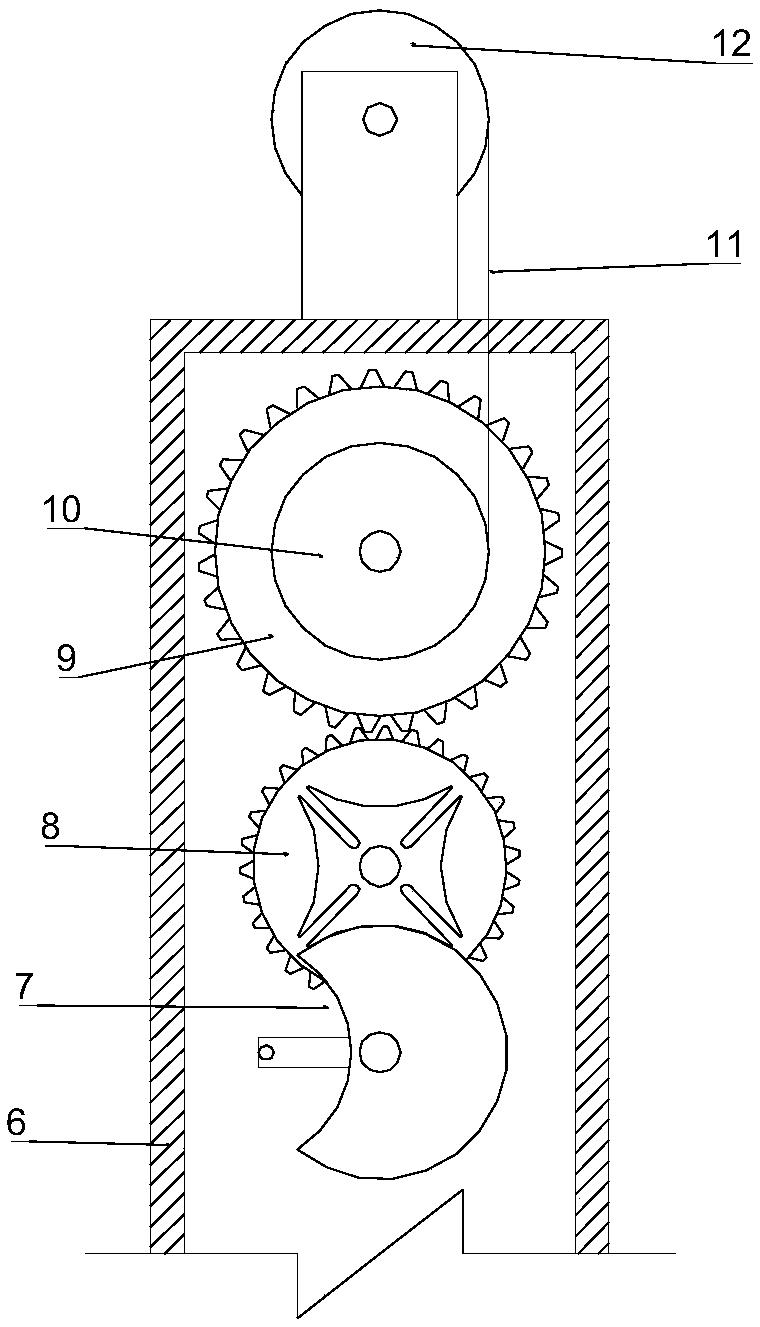

[0023] An adjustment device for engineering hydraulic supports, please refer to figure 1 , including a support plate 1 and a self-locking universal roller 2 installed on the lower surface of the support plate 1, a hollow box 6 is fixedly connected to the upper surface of the support plate 1, a transmission device is installed in the hollow box 6, and the output end of the transmission device is fixedly connected There is a storage roller 10, a connecting belt 11 is wound on the storage roller 10, a rotating handle 19 is provided on the outside of the support plate 1, a height adjustment device is fixedly connected to the support plate 1, and the top end of the height adjustment device is fixedly connected with a displacement Adjusting device, the support plate 1 is fixedly connected with a slide rail 3, the two ends of the slide rail 3 are fixedly connected with the limit block 4, the slide rail 3 is slidably connected with a sliding sleeve 5, and the sliding sleeve 5 is fixedl...

Embodiment 2

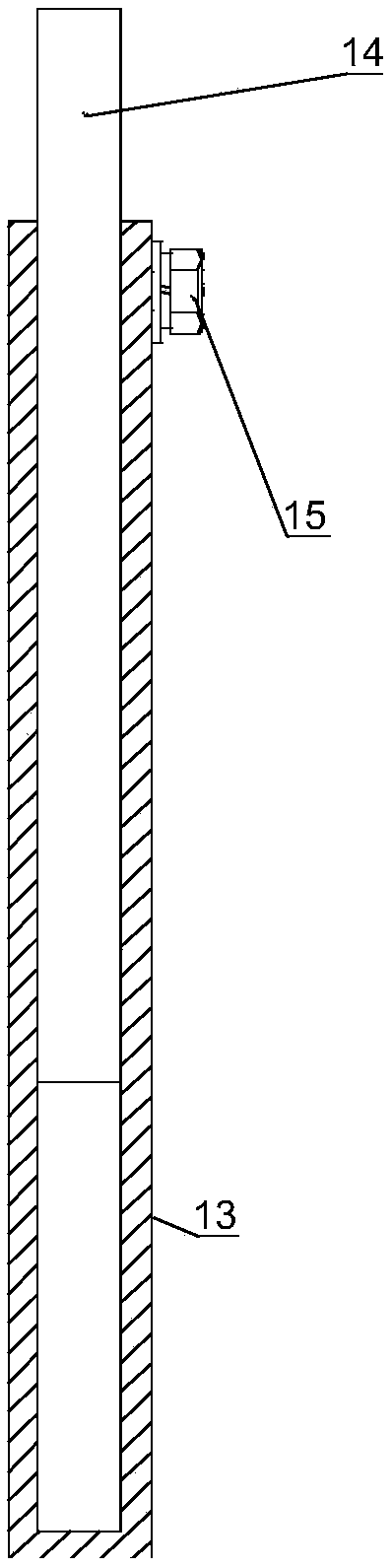

[0027] On the basis of Example 1, please refer to Figure 2-3 , the hollow box 6 is fixedly connected with a guide roller 12, the connecting belt 11 passes through the guide roller 12, the height adjustment device includes a hollow sleeve A13 fixedly connected with the support plate 1, and a free column passes through the hollow sleeve A13 Body A14, bolt A15 is installed on the hollow sleeve body A13, the displacement adjustment device includes a hollow sleeve body B16 fixedly connected with the top of the height adjustment device, a free cylinder B17 passes through the hollow sleeve body B16, and the hollow sleeve body B16 Bolt B18 is installed on it.

[0028] By loosening the bolts B18 and A15, the positions of the free cylinder B17 and the free cylinder A14 in the hollow casing B16 and the hollow casing A13 can be adjusted respectively. When the free cylinder B17 is adjusted to move left and right, the hydraulic support can be The 20 slides on the slide rail 3 following th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com