A flip assembly device

A technology for assembling devices and flipping components, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of quality error, lengthy process flow between aircraft and supporting fixtures, low assembly efficiency, etc. Multi-position assembly, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

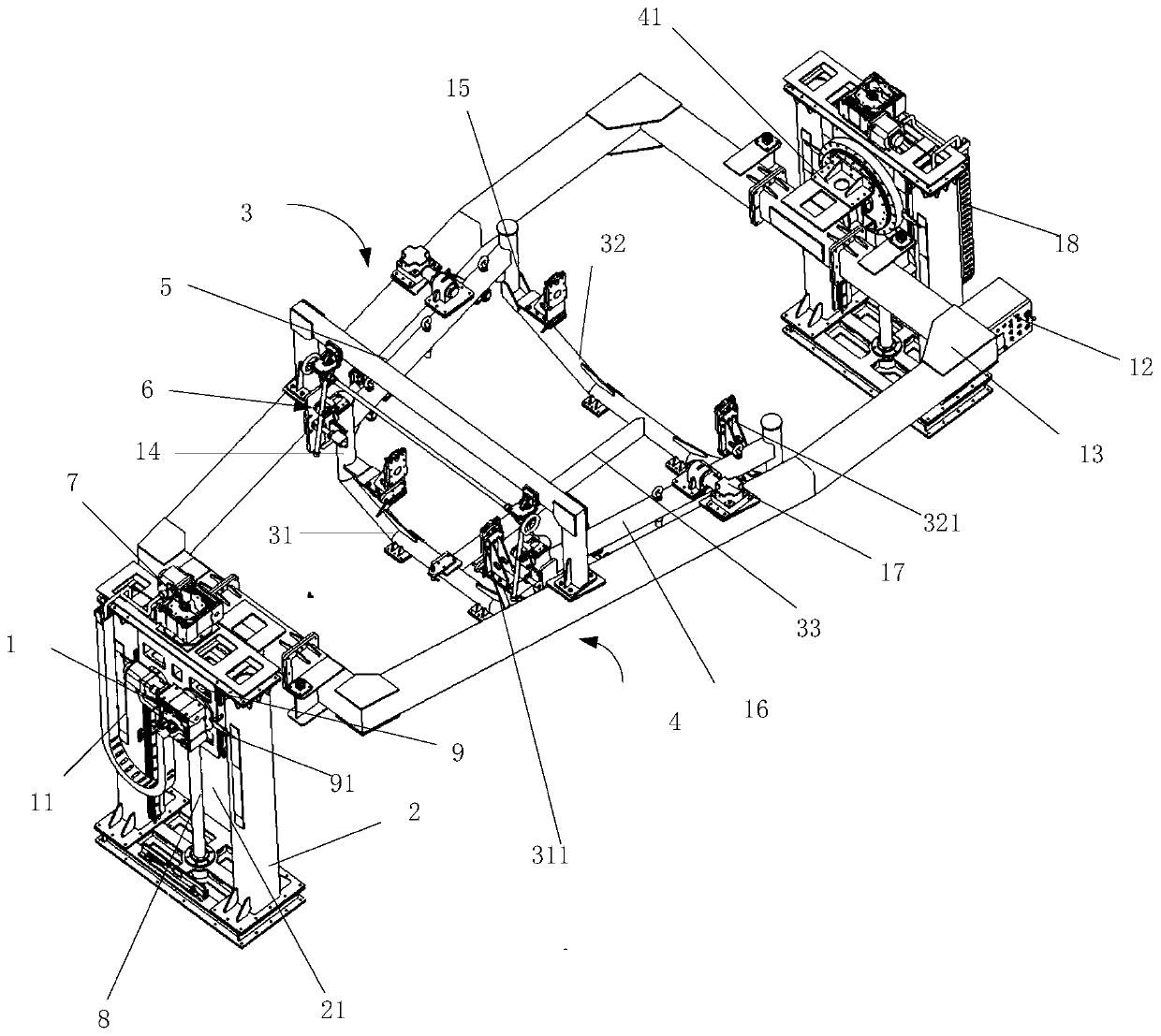

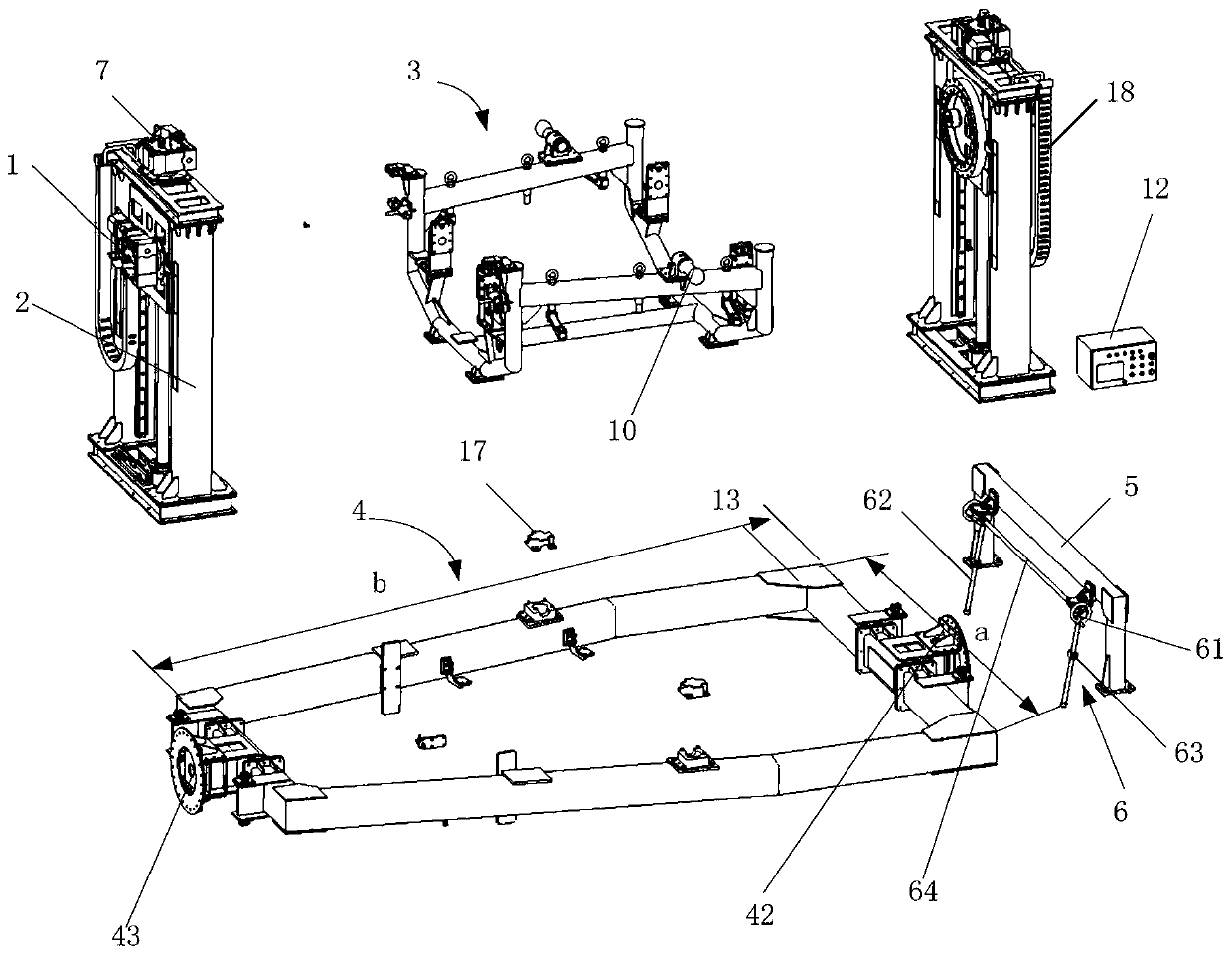

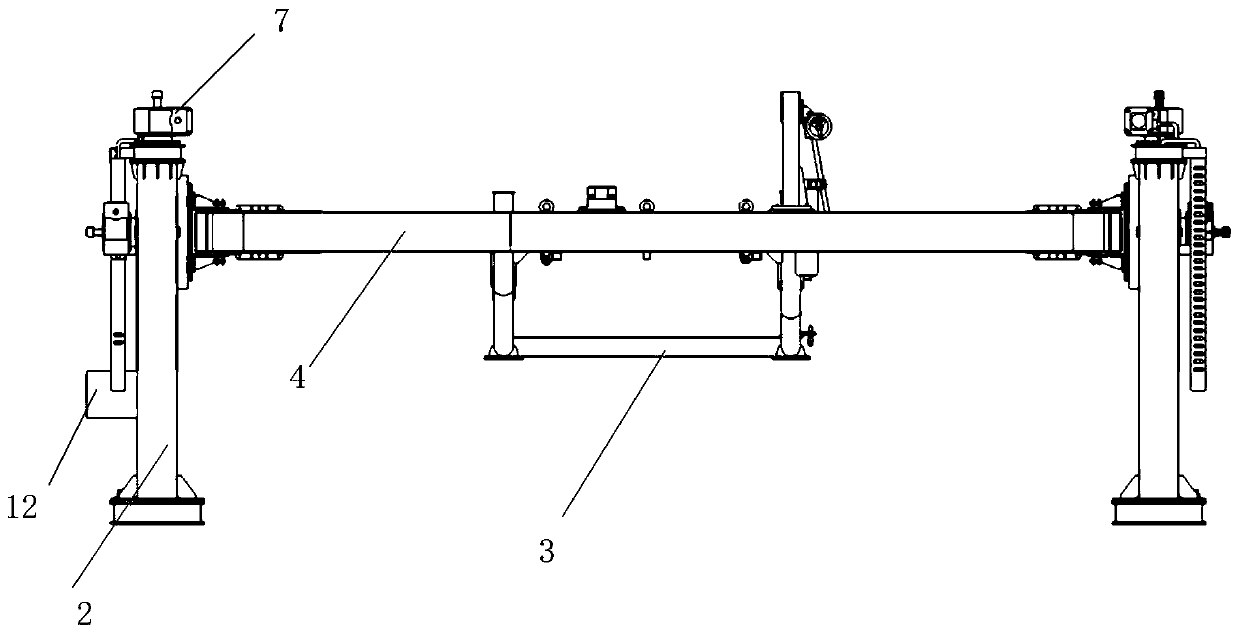

[0040] Such as figure 1 and 2 As shown, this embodiment provides a modularized multi-degree-of-freedom flexible intelligent turning assembly device, including a support component, a controller 12 , a pitch component, two turning components, two lifting components and four sensors 13 .

[0041] Such as figure 2 As shown, the flipping assembly includes a flipping drive motor 1 and a column 2. The column 2 is composed of four rectangular steel profiles up, down, left, and right connected by bolts, and a lifting channel 21 is formed in the middle. The column structure is low in cost and easy to process. Good performance and high assembly precision;

[0042] The lifting assembly includes a lifting drive motor 7, a lifting rod 8 and a lifting part 9. The lifting rod 8 is a screw rod and is arranged along the central axis of the lifting channel 21. The lifting driving motor 7 is arranged on the top of the column 2 and is connected with the lifting rod 8. , the lifting part 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com