Underground coal mine drainage ditch sludge cleaning device

A technology for cleaning devices and drainage ditches, applied in water supply devices, drainage, safety devices, etc., can solve the problems of collection and treatment, blockage of mud pumping, inability to isolate garbage and stones, and achieve the effect of easy adjustment and expansion of the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

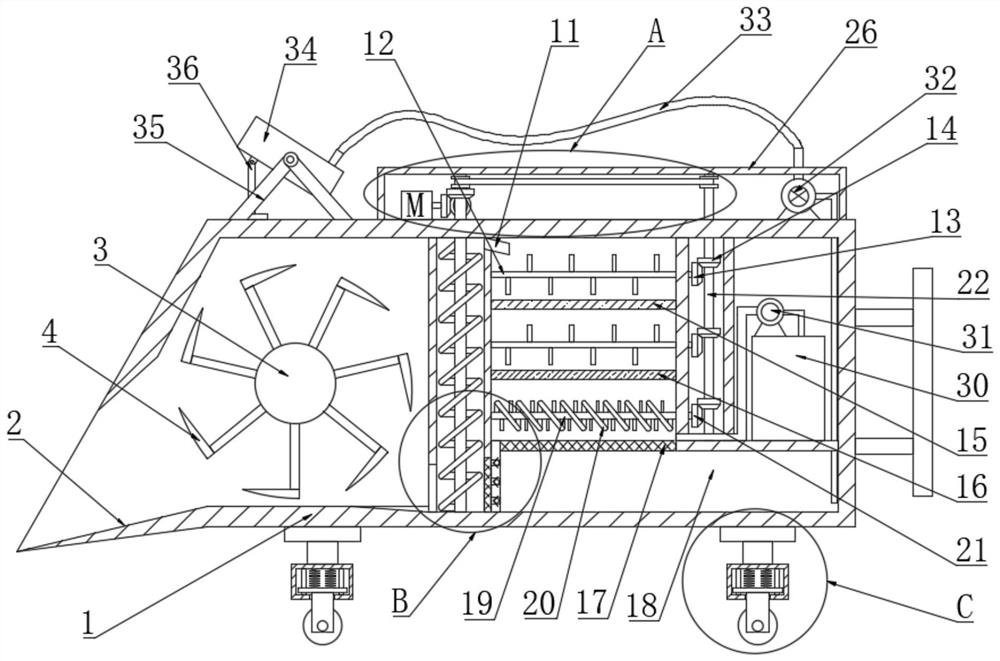

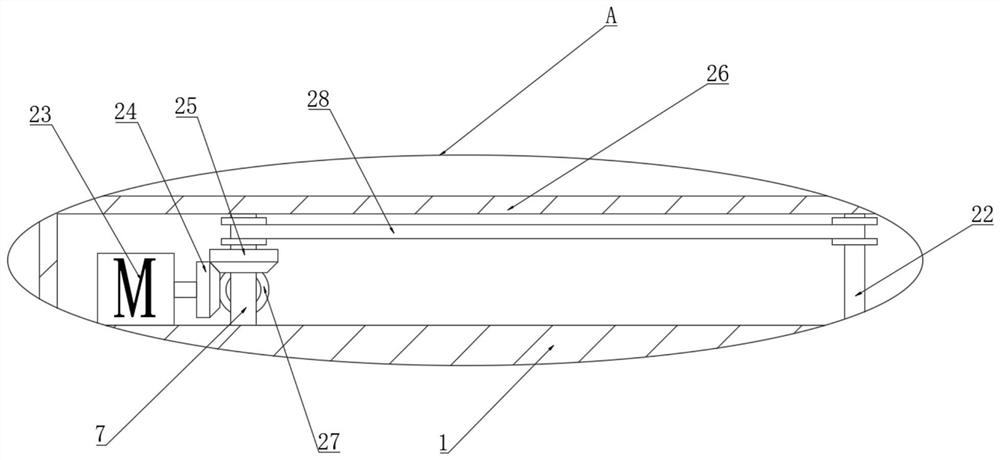

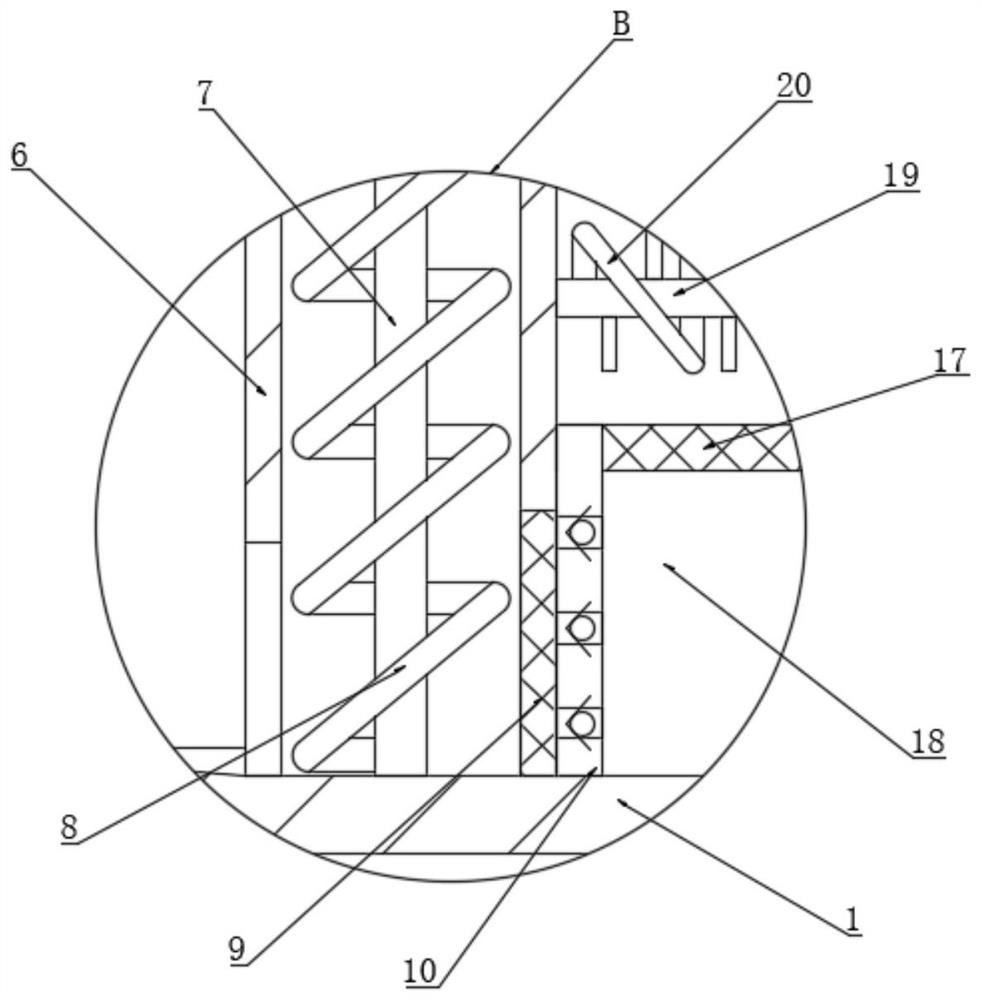

[0029] see Figure 1 to Figure 7, a coal mine underground drain sludge cleaning device, comprising a device body 1, a shovel plate 2 is arranged obliquely below one end of the device body 1, and a stirring and dredging assembly is arranged on one side of the shovel plate 2, and the stirring and dredging assembly The silt assembly includes a first rotating shaft 3 and a dredging shovel 4, and one side of the dredging shovel 4 is provided with a feeding assembly, and the feeding assembly includes a feeding bin 6, a feeding shaft 7 and a first Jiaolong blade 8, The bottom of the conveying bin 6 is provided with a gap for feeding and a first water filter 9 and a sieve plate 10 for draining, the sieve plate 10 is provided with several one-way valves, the The top is fixedly connected with a discharge pipe 11 for easy discharge, and the top of the device body 1 where the feeding shaft 7 is extended is connected with a rotary drive assembly, the rotary drive assembly includes a motor ...

Embodiment 2

[0041] see Figure 1 to Figure 7 , a coal mine underground drainage ditch mud cleaning device, including a device body 1, above the front end of the device body 1 is provided with a water spray device 34 that is convenient for spraying and dust reduction, and the water spray device 34 passes through an elastic hose 33, a water pump 32 and The pipeline communicates with the inside of the water storage chamber 18 , and a first electric telescopic rod 36 for pitch adjustment is arranged below the water spray device 34 .

[0042] Further, the water pump 32 communicates with the interior of the water storage chamber 18 through a pipe, and the water pump 32 is fixedly connected to the top of the device body 1 .

[0043] Further, the water spray equipment 34 is rotatably connected to the top of the device body 1 through a support frame 35, and the piston rod of the first electric telescopic rod 36 is hinged below the water spray equipment 34 through a hinge. Rod 36 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com