Yaw greasing method and device, computer readable storage medium

A yaw and yaw bearing technology, which is applied in the direction of engines, mechanical equipment, wind turbines, etc., can solve the problems of reducing the power generation of wind turbines, unfavorable stable operation of wind turbines, frequent shutdown of wind turbines, etc., to avoid power generation The effect of volume loss, ease of promotion and use, and reduction of downtime and downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Features and exemplary embodiments of various aspects of the invention will be described in detail below. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention.

[0035] Embodiments of the present invention provide a yaw fatting method and device, and a computer-readable storage medium. By adopting the technical solution in the embodiment of the present invention, the yaw bearing can be lubricated during the yaw process of the unit, so as to avoid frequent shutdown of the wind power generation unit.

[0036] It should be noted that the conventional yaw commands of wind turbines include, but are not limited to: crosswind yaw commands, unmooring yaw commands, and windward yaw commands, etc. Yaw operation of any one of the yaw commands.

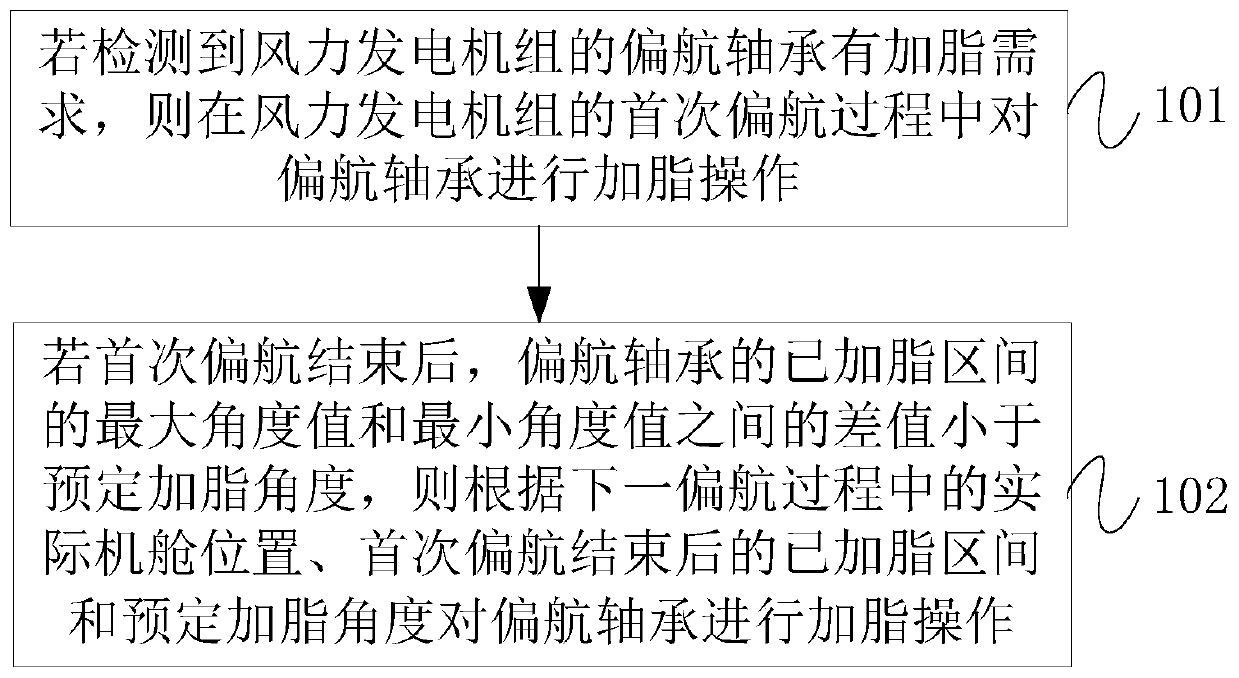

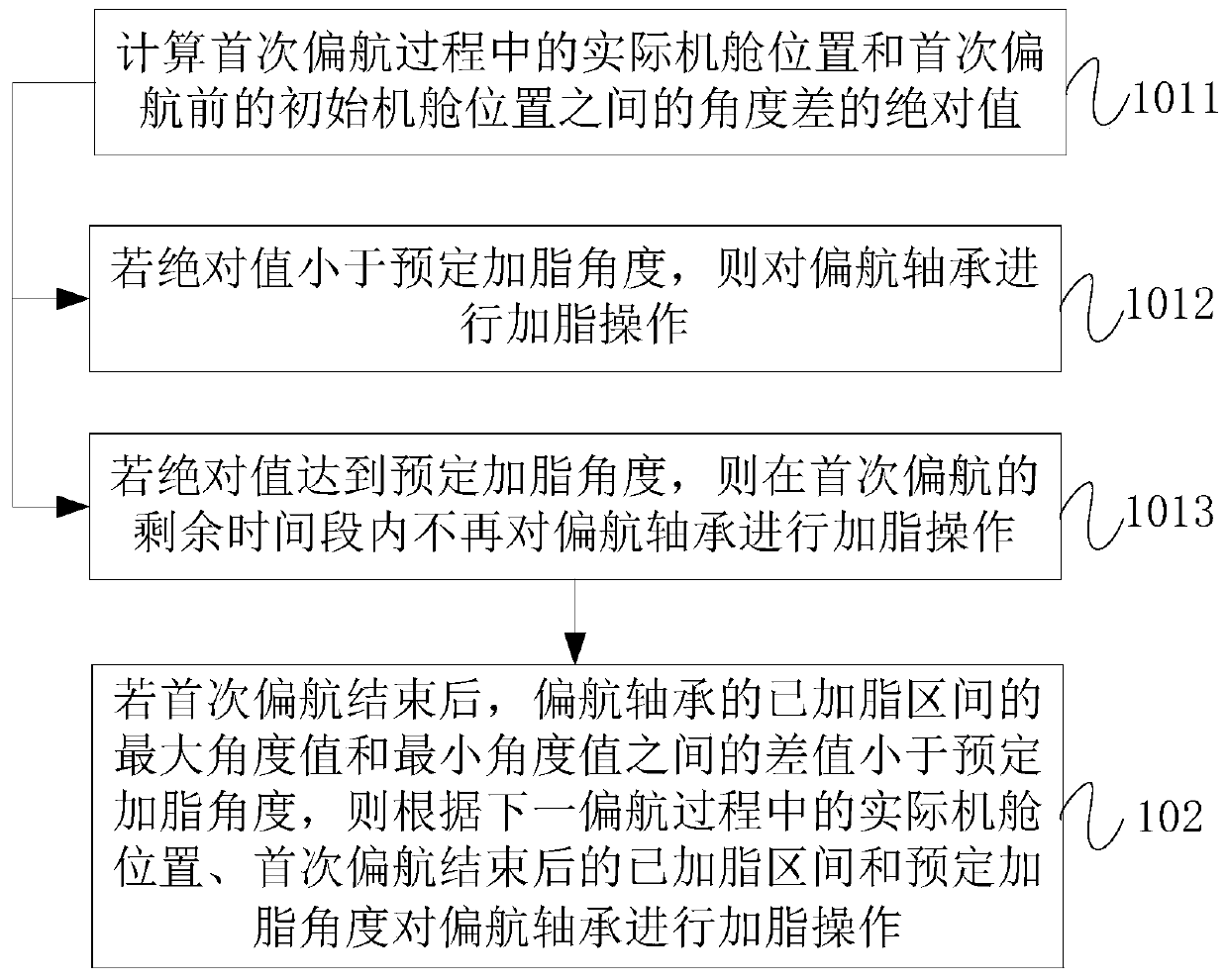

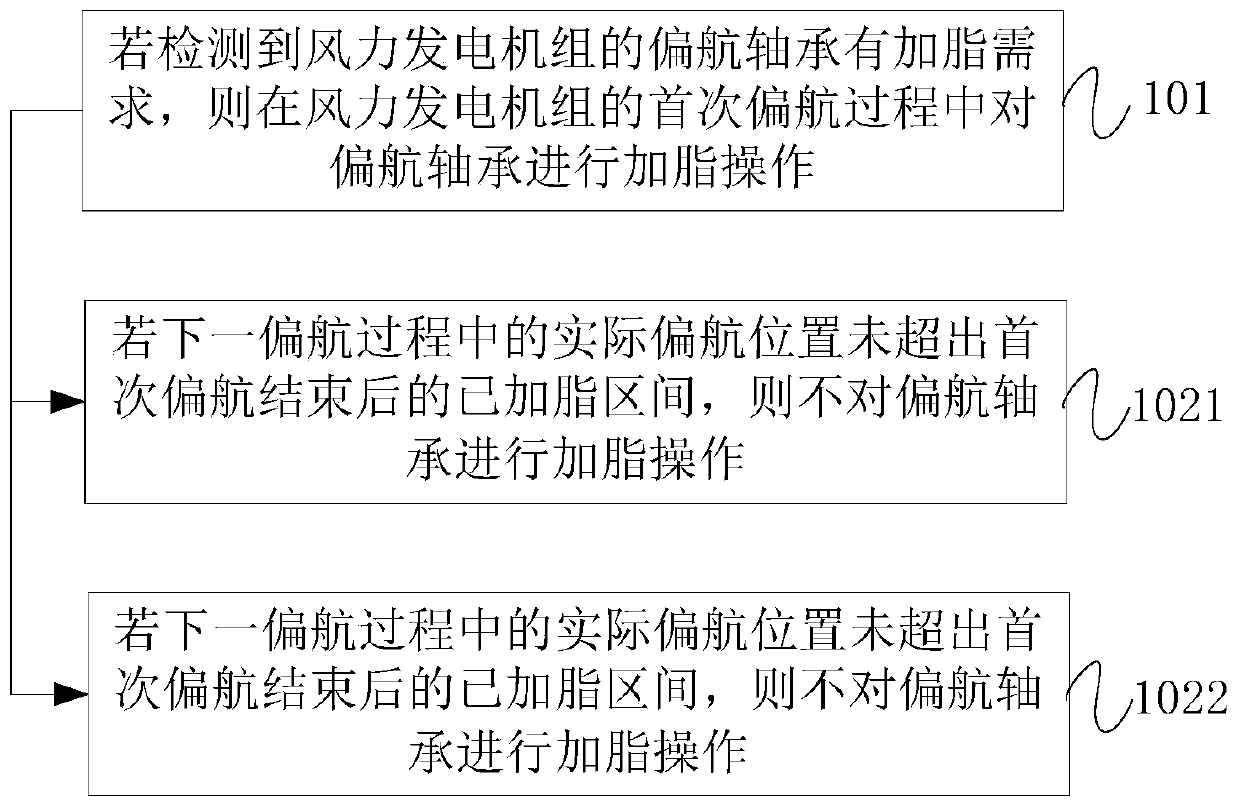

[0037] figure 1 It is a schematic flow chart of the yaw refueling method provided by an embodiment of the present invention. Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com