Compressor cylinder cutting control method, device and unit and air conditioning system

A technology for air conditioning systems and compressors, applied in heating and ventilation control systems, compressors, compressors with reversible cycles, etc., can solve problems such as failure to cut cylinders, and achieve the effect of ensuring energy efficiency and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0042] In the following description, the use of suffixes such as “module”, “part” or “unit” used to indicate elements is only for facilitating the description of the present invention, and has no specific meaning in itself. Therefore, "module", "part" or "unit" can be used in a mixed manner.

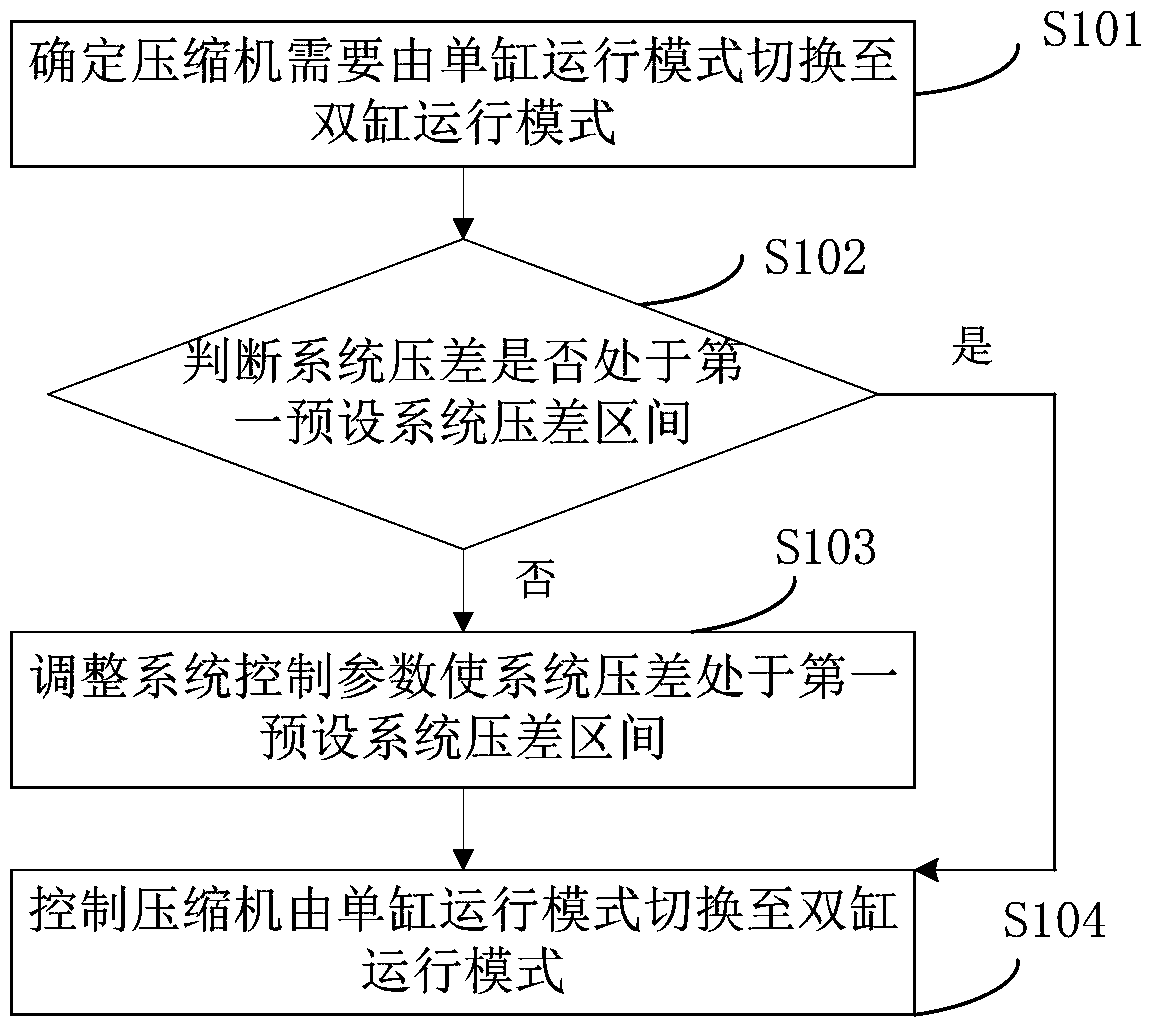

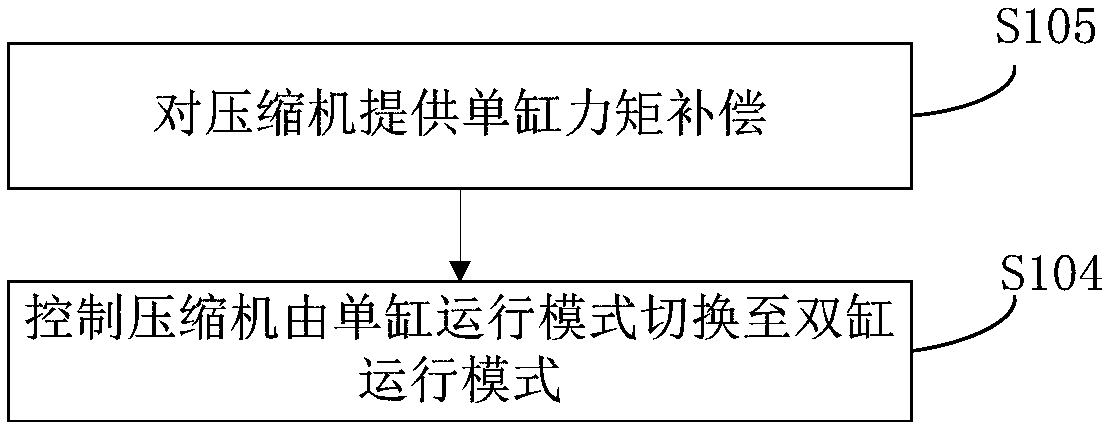

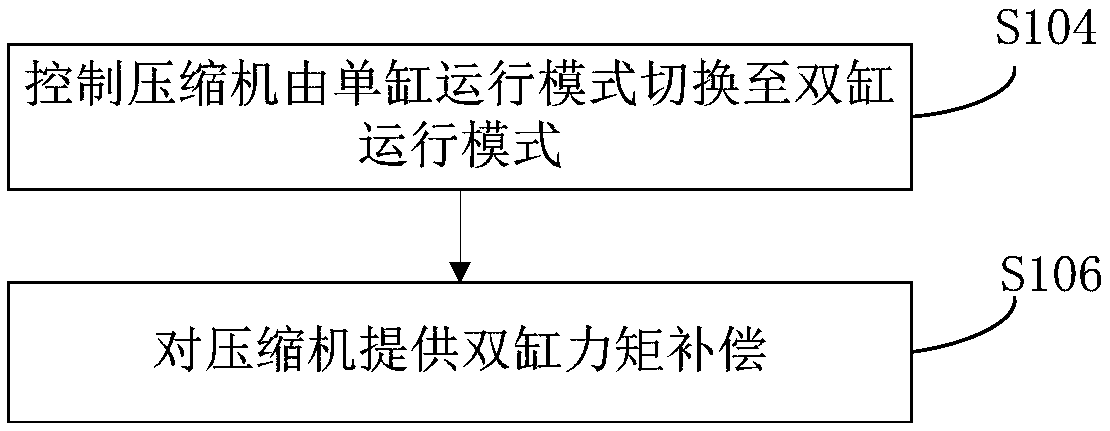

[0043] When the unit is in a special environment, for example, when the unit is in the start-up phase of ultra-low temperature heating, the compressor often cannot switch from single-cylinder operation mode to double-cylinder operation mode. This is because the system pressure difference at this time is small and the rising speed is relatively slow, and the system pressure difference v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com