Eccentric sleeve, oil return device and scroll compressor

A technology of scroll compressors and eccentric sleeves, applied in the field of compressors, can solve problems affecting the heat dissipation and lubrication effects of compressors, and achieve the effects of improving service life and oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

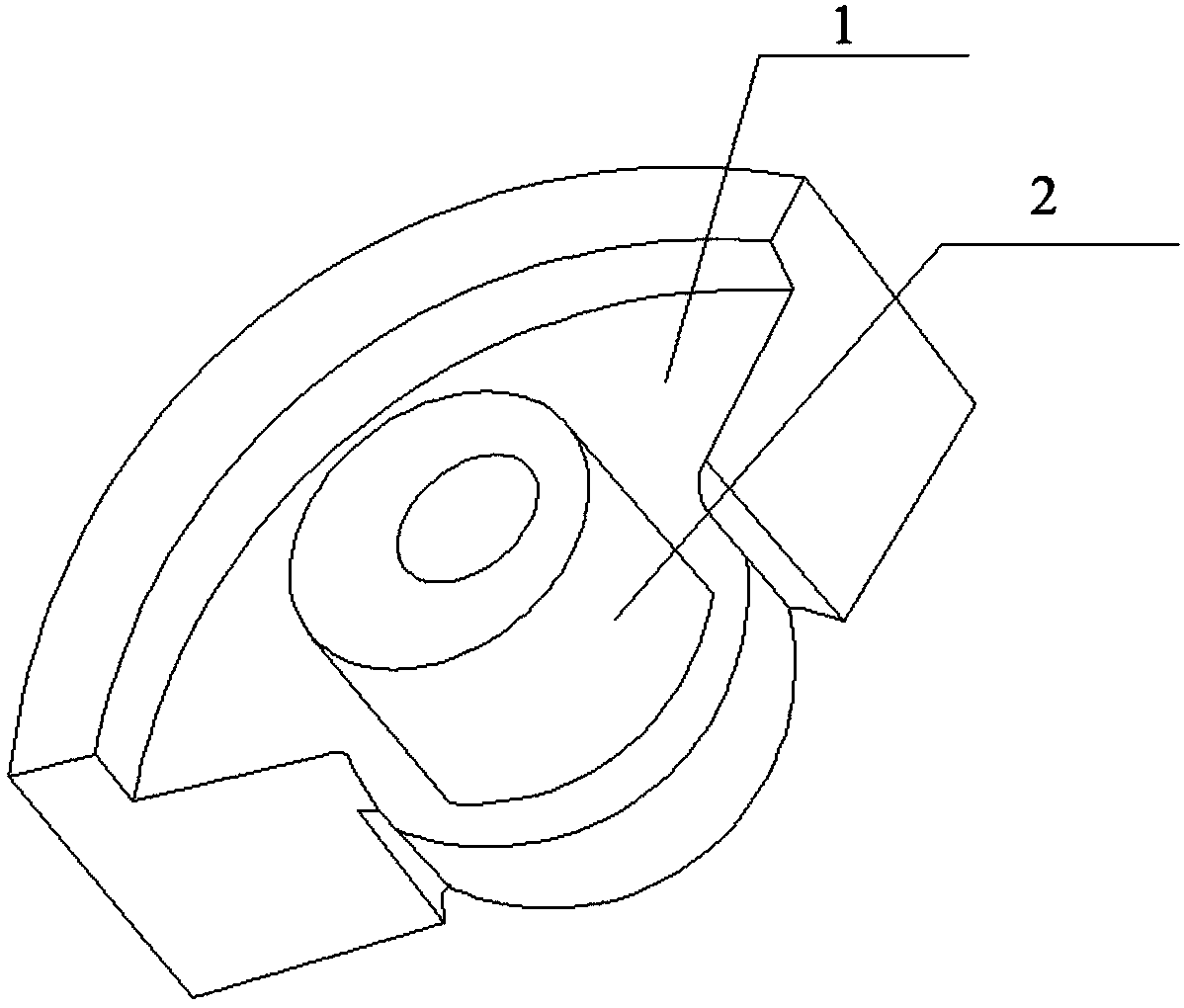

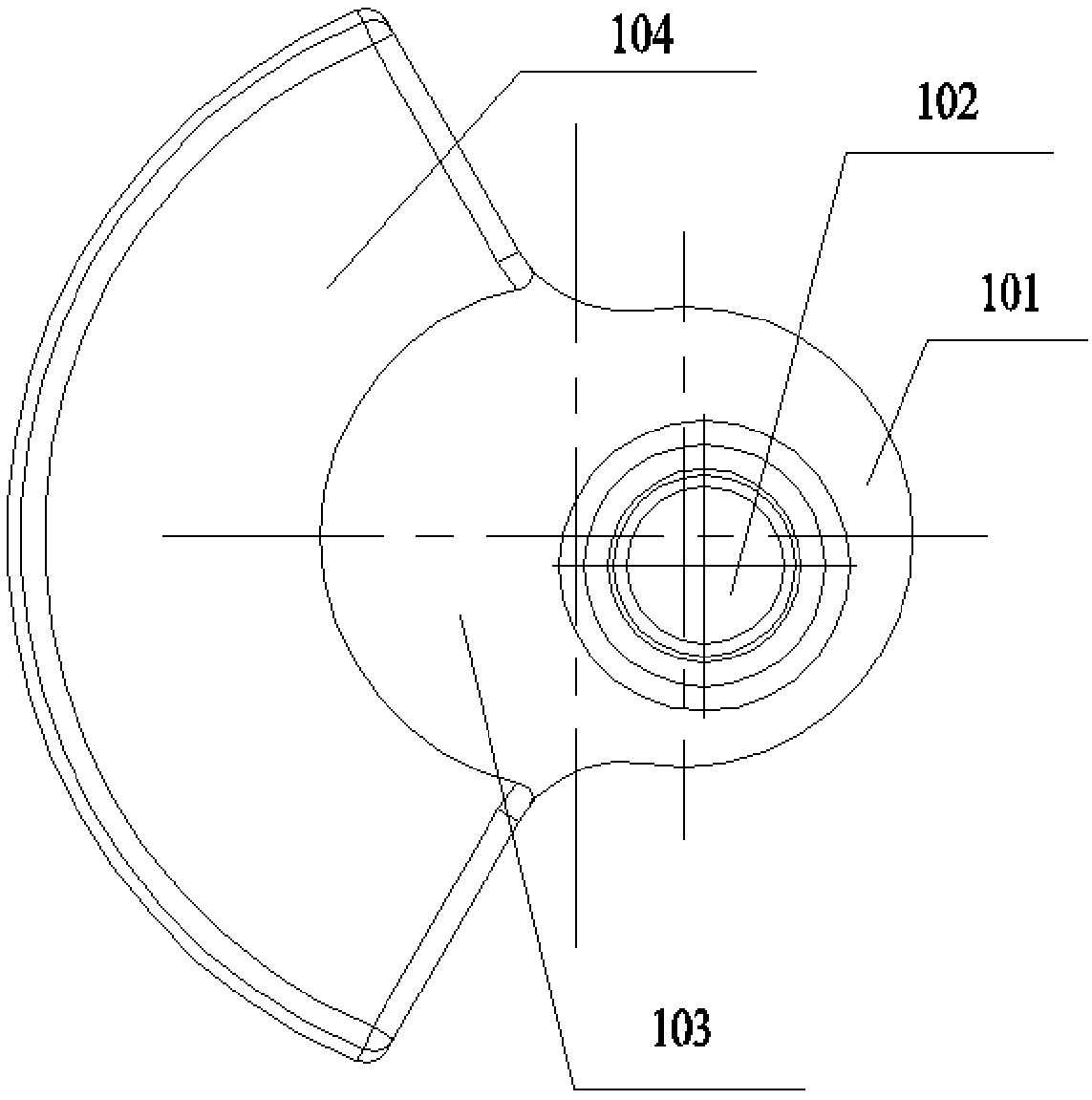

[0032] combine Figure 4 and Figure 5 The eccentric sleeve of this embodiment will be described in detail.

[0033] The eccentric sleeve of the present embodiment includes a mounting part 101, and a through hole 102 is formed on the mounting part 101, such as Figure 4 or Figure 5 shown. The crankshaft 2 is assembled in the through hole 102 and forms a gap with the through hole 102 , and at least one oil return structure is provided on the installation part 101 , and the at least one oil return structure communicates with the gap.

[0034] In this embodiment, at least one oil return structure is provided on the installation part 101 of the eccentric sleeve, and the at least one oil return structure communicates with the gap formed between the crankshaft 2 and the through hole 102, so that the oil return structure appears in the through hole of the installation part during the operation of the compressor. 102 and the yellow grease and impurities on the end face 103 can be...

Embodiment 2

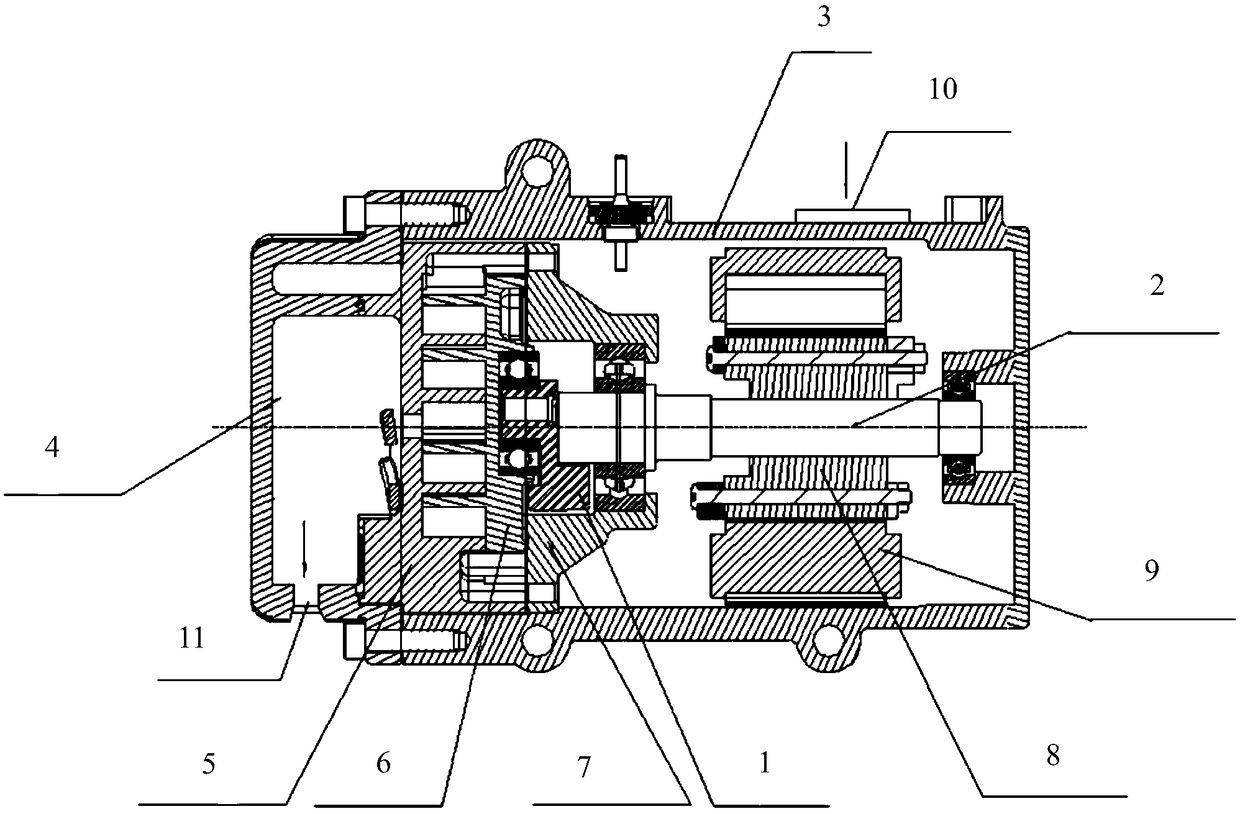

[0051] to combine Image 6 The oil return device and the scroll compressor of this embodiment will be described in detail.

[0052] The oil return device of this embodiment includes at least one oil return structure on the eccentric sleeve of any technical solution of this embodiment. At least one oil return structure on the eccentric sleeve in this embodiment can make the oil return and lubrication at the joints of the eccentric sleeve 1, the crankshaft 2 and the bracket assembly 7 smoother, thereby improving the oil return and lubrication effects of the compressor through the oil circuit circulation , reduce the amount of yellow grease attached, improve the service life of the compressor.

[0053] According to a preferred embodiment, the lubrication circuit of the preferred technical solution of this embodiment needs to pass through the following components: such as Image 6 As shown, during the operation of the compressor, the low-pressure gas enters the suction cavity th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com