Differential pressure limiting type six-way switch valve for conveying fluid

A six-way switching valve and fluid delivery technology, which is applied to multi-way valves, devices for pressure relief on the sealing surface, and lifting valves, etc., can solve the problem of unsatisfactory performance of valve parts, stuck, heavy workload, etc. problems, to avoid jamming and internal leakage, to avoid crushing the cam, and to improve the movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

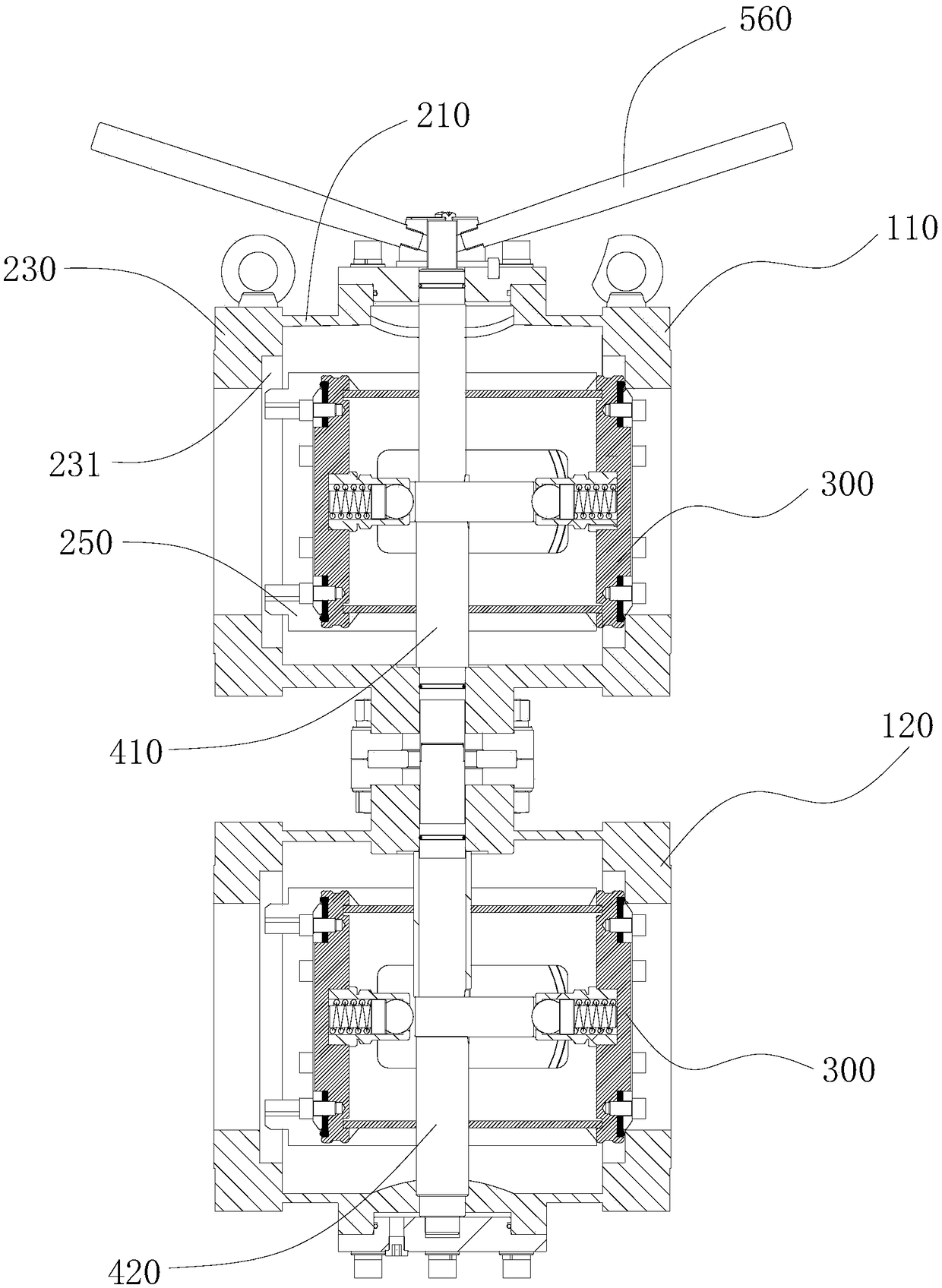

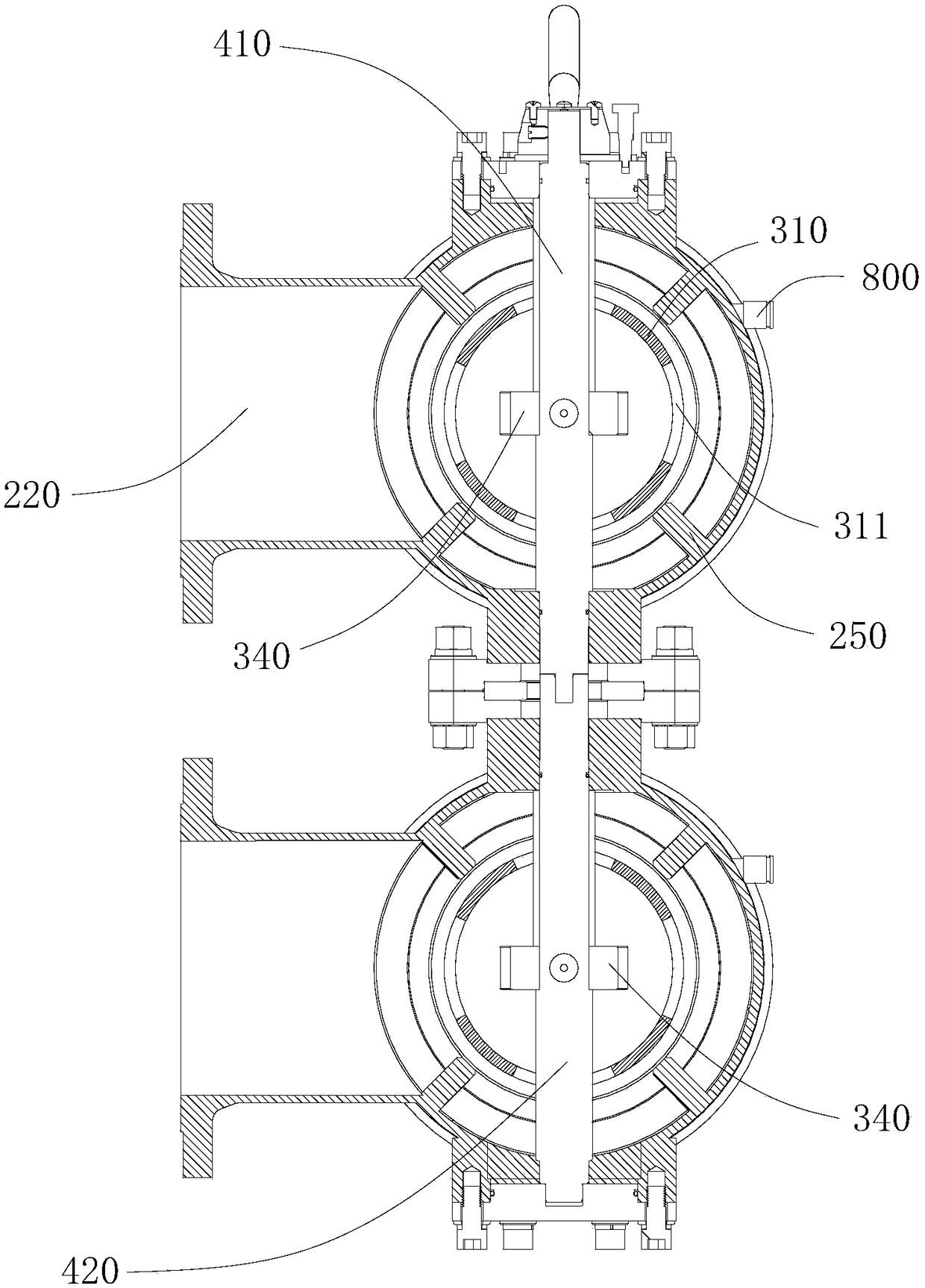

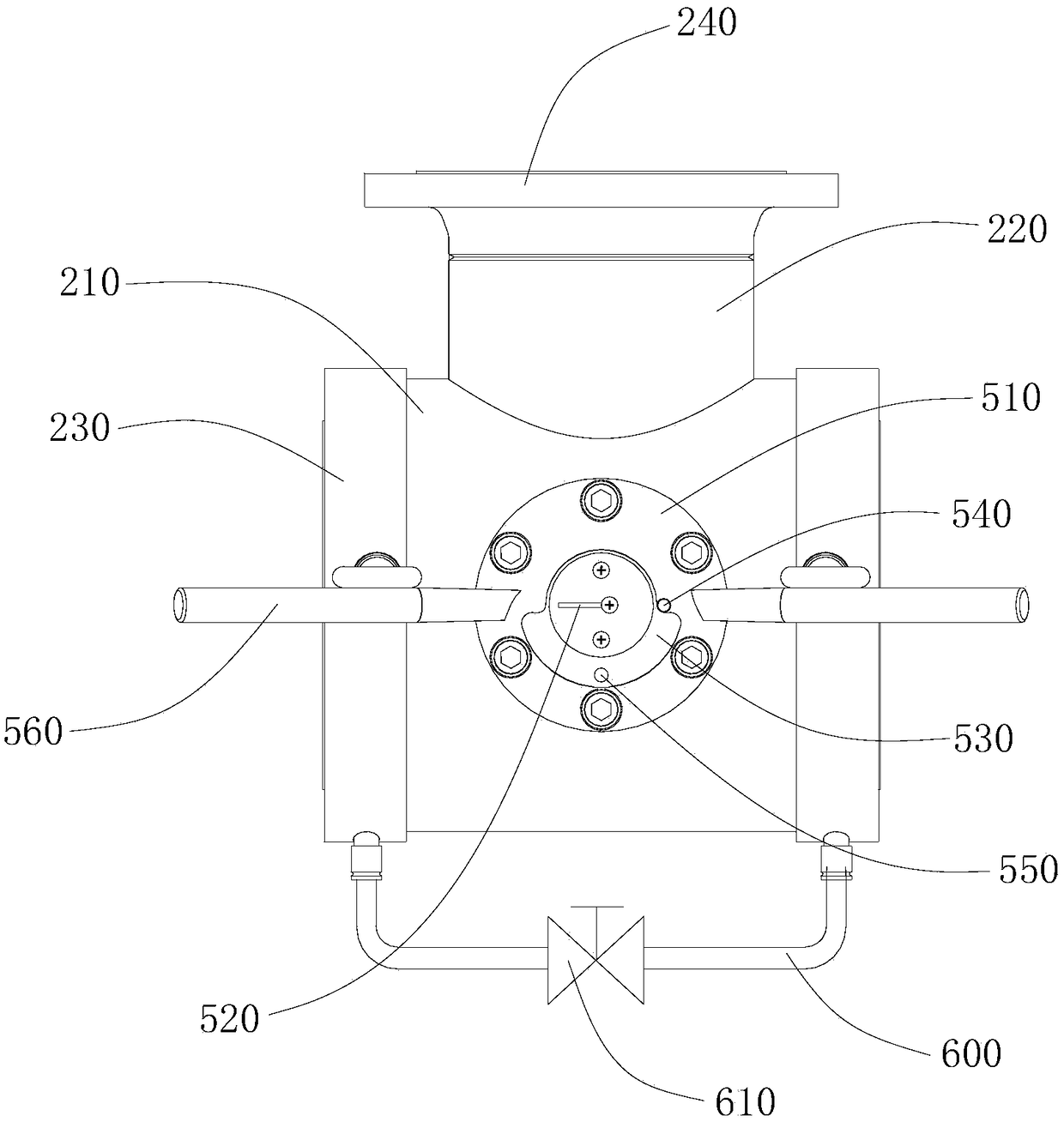

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] like Figure 1 to Figure 3 As shown, a specific embodiment of the present invention discloses a pressure-difference-limiting six-way switching valve for conveying fluids, including a first valve body 110 and a second valve body 120 connected to each other, and the first valve body 110 and the second valve body 120 are connected to each other. The second valve body 120 includes a pipe body 210 and a main pipe 220 fixed on the side wall of the pipe body 210, the main pipe 220 communicates with the pipe body 210, and both ends of the pipe body 210 are provided with Transition flange 230, the transition flange 230 and the two ends of the pipe body 210 are fixedly connected by bolts, the end of the main pipe 220 is fixedly provided with a connecting flange 240, the connection between the main pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com