Supermode microstructure optical fiber for transmitting orbital angular momentum

A technology of micro-structured optical fibers and transmission tracks, applied in the directions of multi-layer core/clad optical fibers, clad optical fibers, light guides, etc. problems such as the difficulty of solving the problem, so as to achieve the effect of low limit loss and large effective mode area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

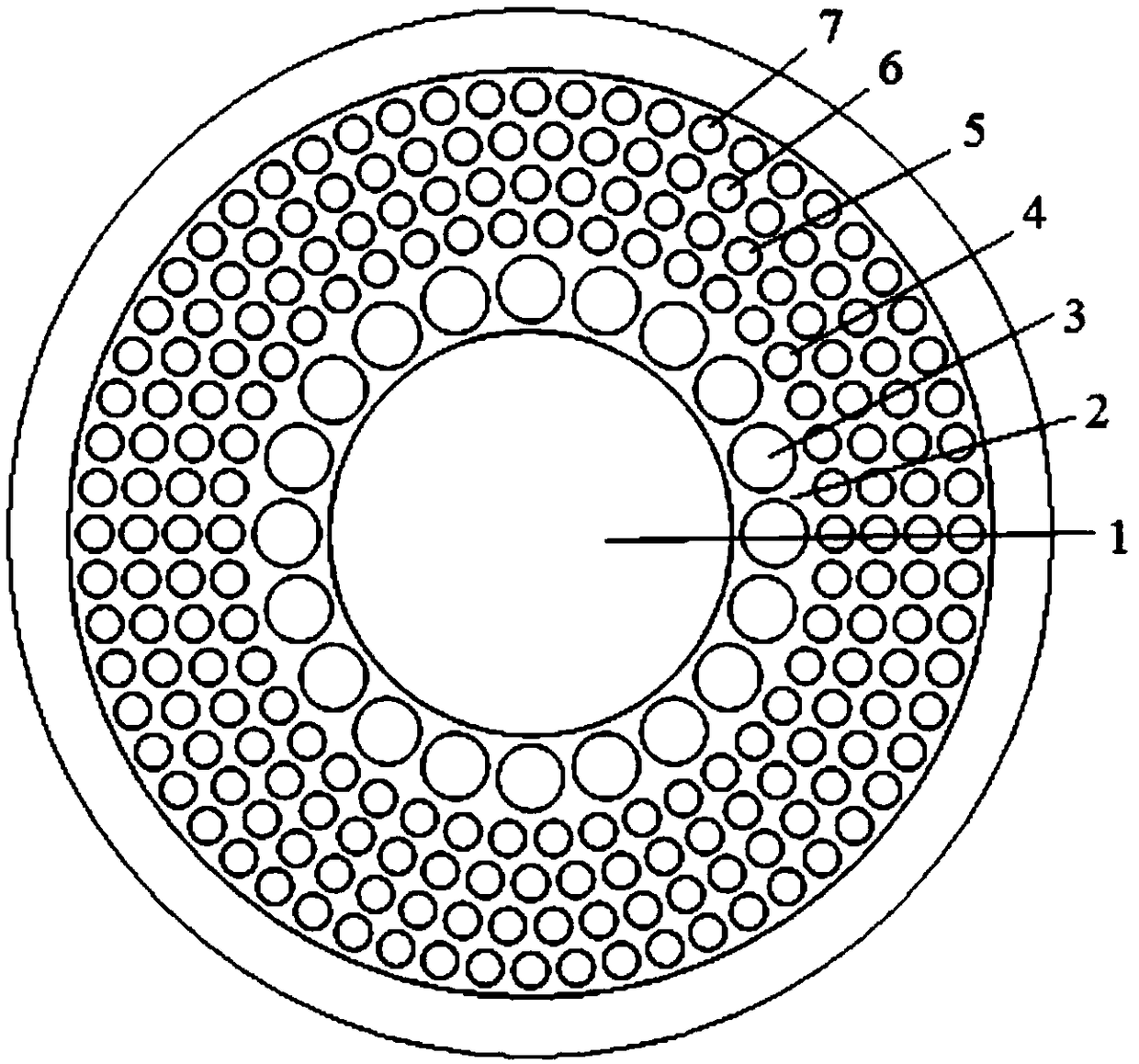

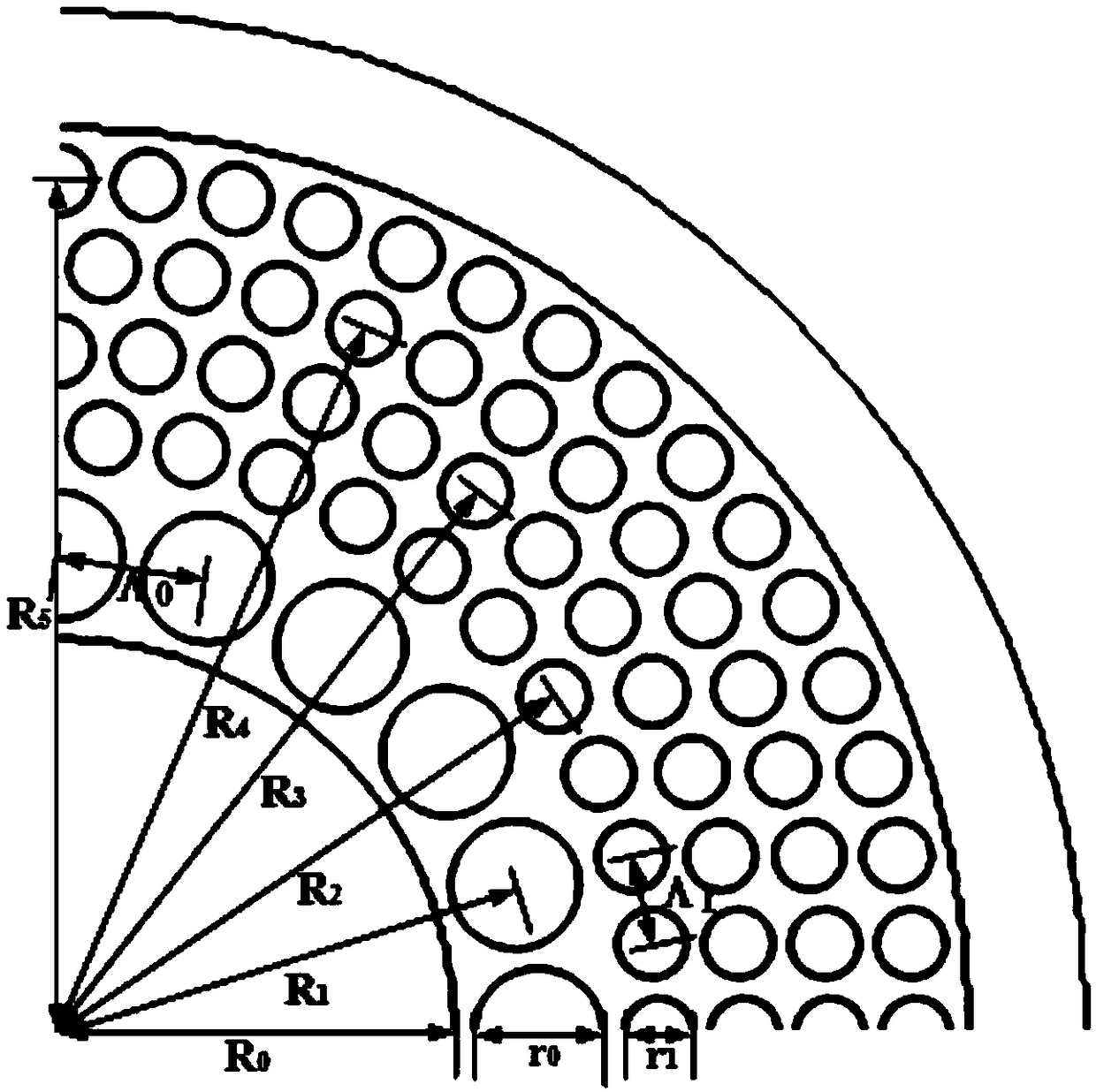

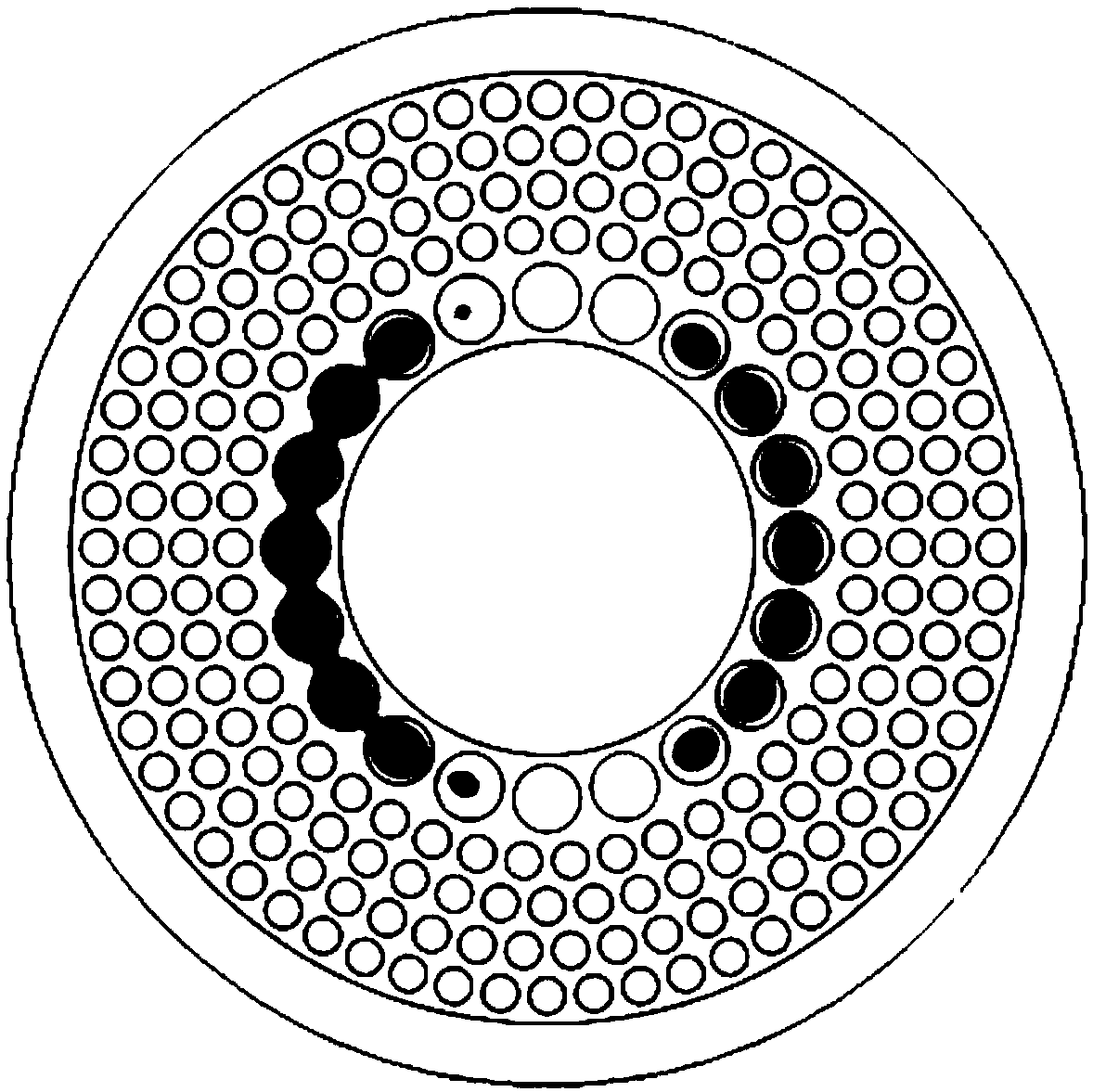

[0042] Embodiment 1: The radius R of the central air hole 1 0 =18.4um; the substrate 2 is pure silica glass; the refractive index of the annular array core region 3 doped quartz column is n at the wavelength of 1.55um 1 = 1.457, radius r 0 =2.98um, the distance to the fiber center is R 1 =22.2um, the distance between two adjacent doped quartz columns Λ 0 =6.95um; the air hole radius r of the first cladding layer 4, the second cladding layer 5, the third cladding layer 6 and the fourth cladding layer 7 in the fiber cladding area 1 =1.58um, the center distance R of 4 pairs of optical fibers in the first cladding layer 2 =27.8um, distance R between 5 pairs of optical fibers in the second cladding layer 3 =31.8um, distance R between 6 pairs of optical fibers in the third cladding layer 4 =35.8um, the fourth cladding 7 pairs of fiber center distance R 5 = 39.8um. The spacing Λ of adjacent air holes in the first cladding layer 4, the second cladding layer 5, the third claddin...

Embodiment 2

[0043] Embodiment 2: The radius R of the central air hole 1 0 =18.6um; the substrate 2 is pure silica glass; the refractive index of the annular array core region 3 doped quartz column is n at the wavelength of 1.55um 1 = 1.463, radius r 0 =3.02um, the distance to the fiber center is R 1 =22.6um, the distance between two adjacent doped quartz columns Λ 0 =7.07um; the air hole radius r of the first cladding layer 4, the second cladding layer 5, the third cladding layer 6 and the fourth cladding layer 7 of the optical fiber cladding area 1 =1.62um, the center distance R of 4 pairs of optical fibers in the first cladding layer 2 =28.2um, distance R between 5 pairs of optical fibers in the second cladding layer 3 =32.2um, distance R between 6 pairs of optical fibers in the third cladding layer 4 =36.2um, the fourth cladding 7 pairs of fiber center distance R 5 = 40.2um. The spacing Λ of adjacent air holes in the first cladding layer 4, the second cladding layer 5, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com