A wire-to-wire lightning circuit with a lower clamping voltage

A technology of clamping voltage and lightning protection circuit, which is applied in the field of LED power drive, can solve problems such as high residual voltage of the circuit, poor power supply lightning resistance, damage to LED drive power supply and lamp board, etc., to suppress transient surges and improve The effect of lightning resistance and low clamping voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

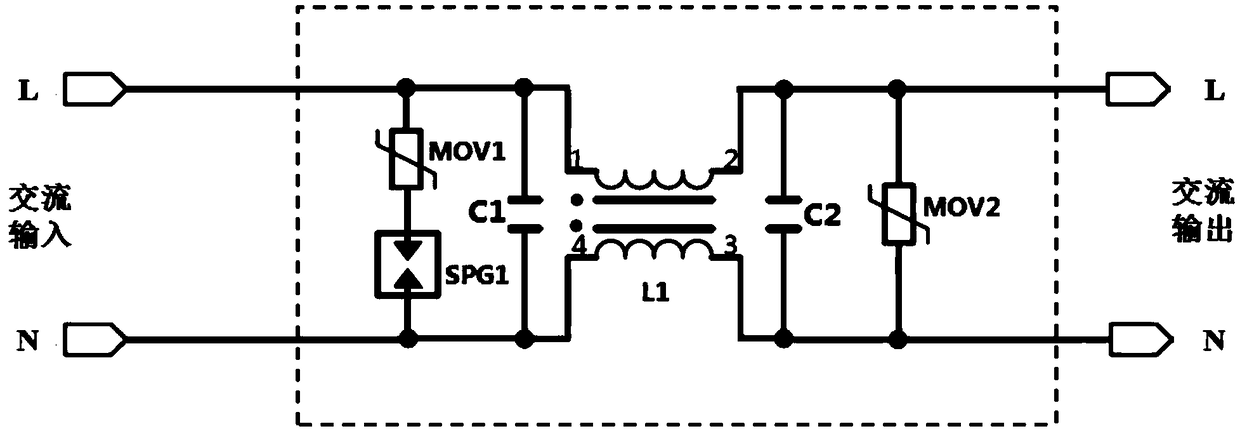

[0013] A line-to-line lightning protection circuit with a lower clamping voltage provided by an embodiment of the present invention, its electrical connection relationship is as follows figure 1 shown. In this embodiment, the line-to-line lightning protection circuit with lower clamping voltage is applied to LED power drive, and is specifically improved in the existing EMI circuit. The line-to-line lightning protection circuit of the embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com