Lightning-stroke-resistant composite coating, spraying method thereof and lightning-stroke-resistant aluminum skin

A composite coating and anti-lightning technology, applied in the field of anti-lightning composite coating and anti-lightning aluminum skin, can solve problems such as detonation, and achieve the effects of reducing temperature rise, improving safety performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

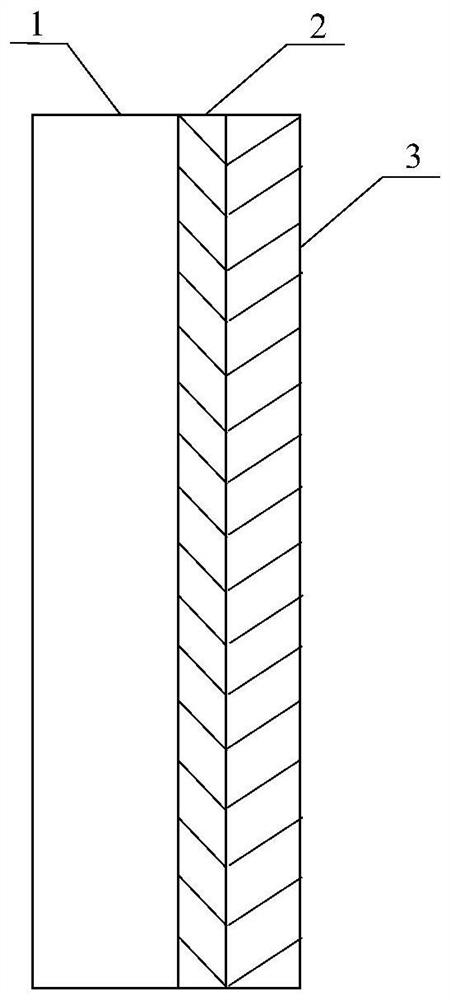

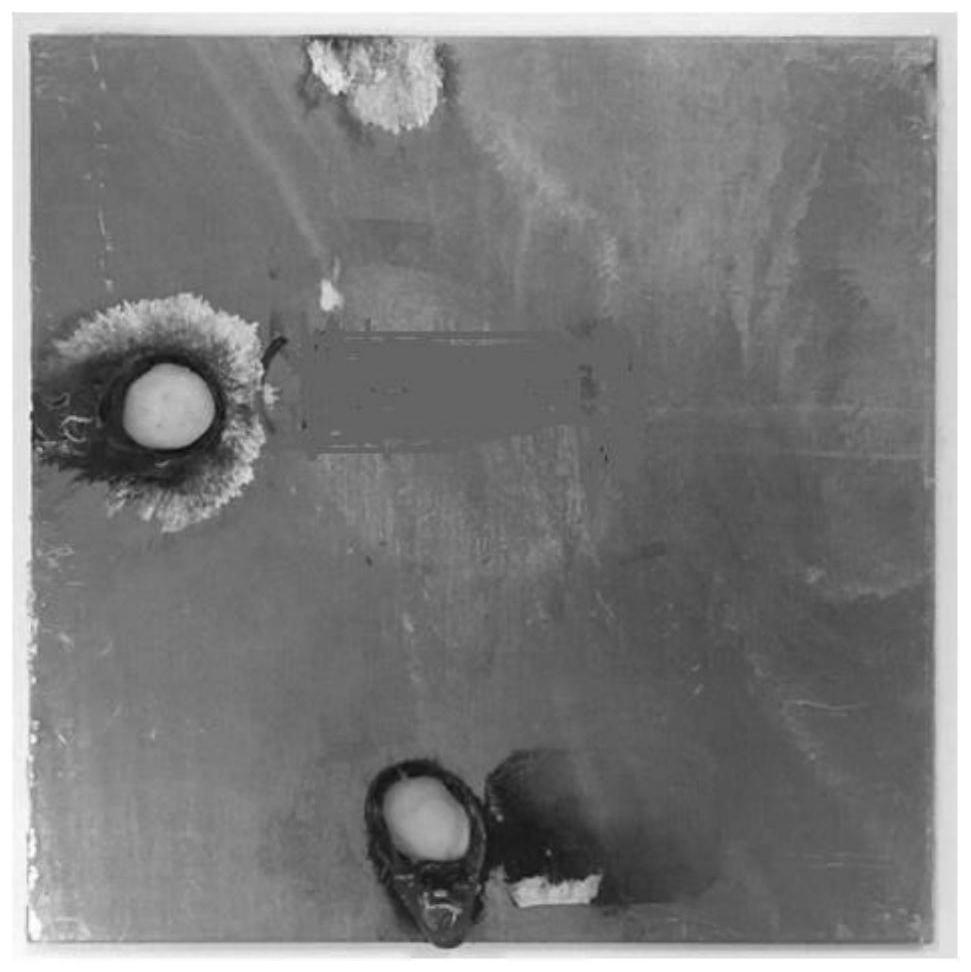

Image

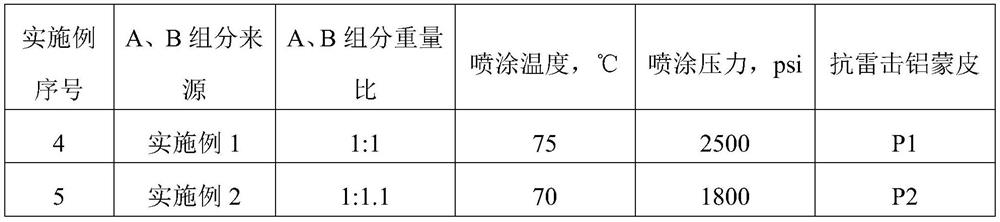

Examples

Embodiment 1

[0048] In parts by weight, 28 parts of hydroxyl-terminated polyether BASF LF901; 23 parts of isocyanate resin Huntsman 5005; 23 parts of fluorosilicon modified resin; 13 parts of closed-cell ceramic powder with a diameter of 80 microns; 7 parts of carbon nano-conductive scales parts, and a total of 6 parts of reactive diluent RD-601, German BYK-344 leveling agent and BASF yellow color paste, mixed to obtain A1 component. In parts by weight, 53 parts of amino-terminated resin; 25 parts of BASF chain extender ADR4368C; 6 parts of carbon nano-conductive flakes; German BYK-344 leveling agent, German Henkel company Texaphor dispersant, French SYNTHRO-THIX 905S thickener agent and 16 parts of German BYK-420 anti-settling agent, mixed to obtain B1 component.

Embodiment 2

[0050] In parts by weight, 26 parts of hydroxyl-terminated polyether BASF LF901; 25 parts of isocyanate resin Japan MR200; 22 parts of silicone resin; 10 parts of closed-cell perlite with a diameter of 50 microns; Thinner RD-601, German BYK-344 leveling agent and BASF yellow colorant total 10 parts, mix to get A2 component. In parts by weight, take 50 parts of amino-terminated resins; 25 parts of BASF amino chain extender ARD4370; 6 parts of carbon nano-conductive scales; German BYK-344 leveling agent, German Henkel company Texaphor dispersant, French SYNTHRO-THIX 905S additive Thickener and 19 parts of German BYK-420 anti-sedimentation agent were mixed to obtain B2 component.

Embodiment 3

[0052] In parts by weight, 30 parts of hydroxyl-terminated polyether BASF LF901; 23 parts of isocyanate resin Bayer 44V20; 20 parts of fluororesin; 10 parts of closed-cell glass microspheres with a diameter of 10 microns; 7 parts of carbon nanoconductive scales and active dilution A total of 10 parts of agent RD-601, German BYK-344 leveling agent and BASF yellow color paste were mixed to obtain A3 component. In parts by weight, take 50 parts of amino-terminated resin; 22 parts of American secondary ammonia chain extender G18; 5 parts of carbon nano-conductive flakes; German BYK-344 leveling agent, German Henkel company Texaphor dispersant, French SYNTHRO-THIX 905S A total of 16 parts of thickener and German BYK-420 anti-settling agent, and 7 parts of aluminum powder pigment are mixed to obtain component B3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com