Composite insulator

A technology of composite insulators and insulating blocks, applied in the direction of insulators, supporting insulators, coatings, etc., can solve the problems of composite insulators such as easy damage, weak performance, short circuit, etc., to improve wind deflection resistance, enhance wind deflection resistance and lightning strike resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

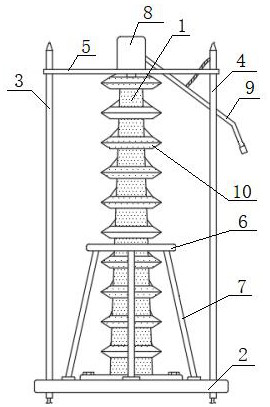

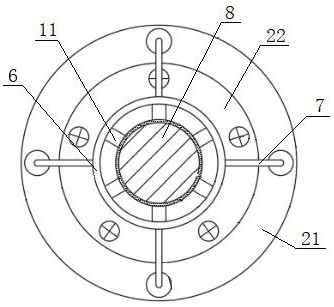

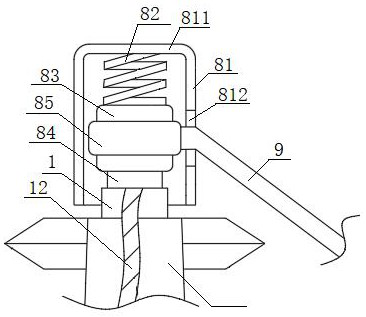

[0040] see Figure 1 to Figure 5 , a composite insulator, including a mandrel 1, six connecting columns 11 uniformly arranged around the circumference of the mandrel 1, a support seat assembly 2, No. 1 lightning arresters 3 and No. 2 arresters symmetrically arranged on the left and right sides of the mandrel 1 Lightning arrester 4, a conductive upper seat 8 located above the mandrel 1, and an arc striker 9. The support seat assembly 2 includes a base 21 and a support pad 22 embedded in the middle of the base 21. The upper surface of the base 21 is provided with There are multiple No. 2 arc spraying through holes 211, the lower end of the mandrel 1 is fixedly connected to the middle part of the support pad 22, the upper end of the mandrel 1 is connected with a transverse connecting rod 5, and the two ends of the transverse connecting rod 5 They are respectively fixedly connected to the upper ends of the No. 1 arrester 3 and the No. 2 arrester 4, and the lower ends of the No. 1 ...

Embodiment 2

[0042] The difference with Example 1 is:

[0043] The mandrel 1 is a tapered structure whose diameter gradually increases from top to bottom, and 10 sheds 10 are arranged on the mandrel 1 from top to bottom, and the outer walls of the mandrel 1 and sheds 10 are coated with Covered with an antifouling coating, the raw material composition and weight ratio of the antifouling coating are: silicone 30, polytetrafluoroethylene 22, fluorine-containing acrylic resin 30, crosslinking agent 25, organic fluoropolymer 17, Polyisocyanate 8, defoamer 7, surfactant 4, catalyst 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com