Anaerobically curable (meth)acrylate compositions

A methacrylate-functional, acrylate-based technology for use in anaerobically curable compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159]

[0160] The methacrylate-functionalized polybutadiene used in Example 1 was a methacrylate (vinyl) terminated butadiene (VTB) polymer with a number average molecular weight of about 4,450. Such VTB polymers are available under the trade name Hypro TM 2000X168LC from Emerald Performance purchased.

[0161]Suitable styrene-butadiene block copolymers are available under the trade names D1155E polymer was purchased from Kraton Performance Polymers. D1155E is a transparent linear block copolymer based on styrene and butadiene with 40% by mass of bound styrene.

[0162] A suitable source of propoxylated bisphenol A fumarate polyester is FILCO 663P, other sources include those commercially available under the tradenames ATLAC 382 and DION 382E.

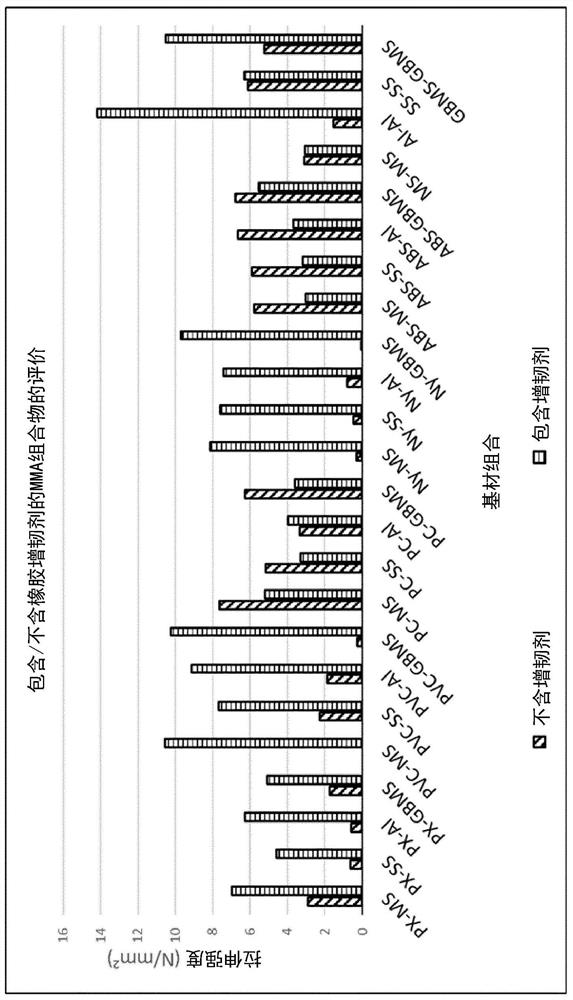

[0163] Figures 1 to 6 The tensile strength of various compositions observed on various substrates is shown. Substrates shown are abbreviated as follows: Perspex (polymethyl methacrylate; "PX"); mild steel ("MS"); stainle...

Embodiment 2

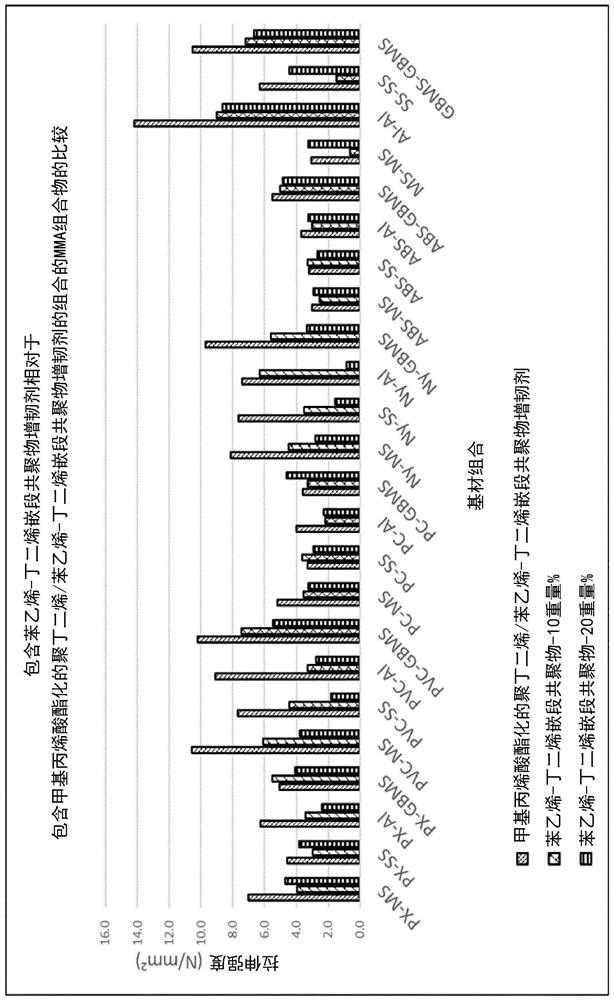

[0165] Example 2 (comparative): The tensile strength properties of methyl methacrylate (MMA) compositions comprising different levels of styrene-butadiene block copolymer on lap shear substrates were evaluated. Compositions comprising 10% and 20% by weight styrene-butadiene block copolymer were prepared as follows.

[0166]

[0167] figure 2 The tensile strength performance of Composition A versus Compositions C and D on various passive substrates is shown. Although the addition of styrene-butadiene block copolymers improved the tensile strength properties on several substrates, the styrene-butadiene block copolymers and methacrylate-functionalized polybutadiene The combination results in improved tensile strength properties.

Embodiment 3

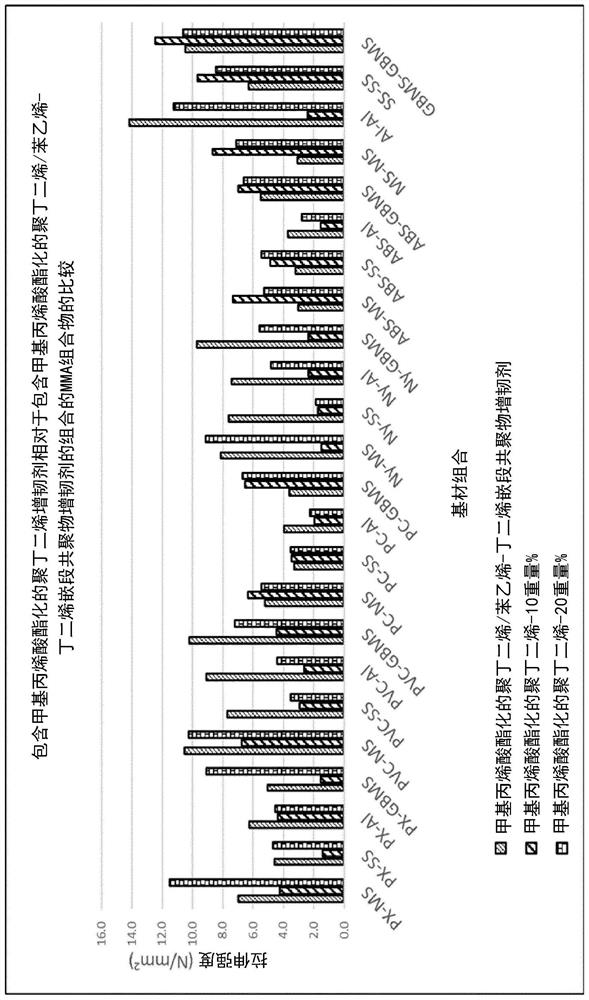

[0168] Example 3 (comparative): The tensile strength properties of MMA compositions comprising different levels of methacrylate functionalized polybutadiene on lap shear substrates were evaluated. Compositions comprising 10% and 20% by weight methacrylate functionalized polybutadiene were prepared as follows.

[0169]

[0170] image 3 The tensile strength performance of Composition A relative to Compositions E and F on various passive substrates is shown. While the incorporation of methacrylate-functionalized polybutadiene improved tensile strength properties on several substrates, styrene-butadiene block copolymers and methacrylate-functionalized polybutadiene The combination results in enhanced tensile strength properties for certain substrates.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap