Dual-purpose semi-feeding motor-driven threshing machine capable of being used in sunny and rainy days

A semi-feeding and threshing machine technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as insufficient protective measures, affecting work efficiency, and inability to continue to use, so as to achieve safe and convenient use, thorough threshing, and time-saving long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

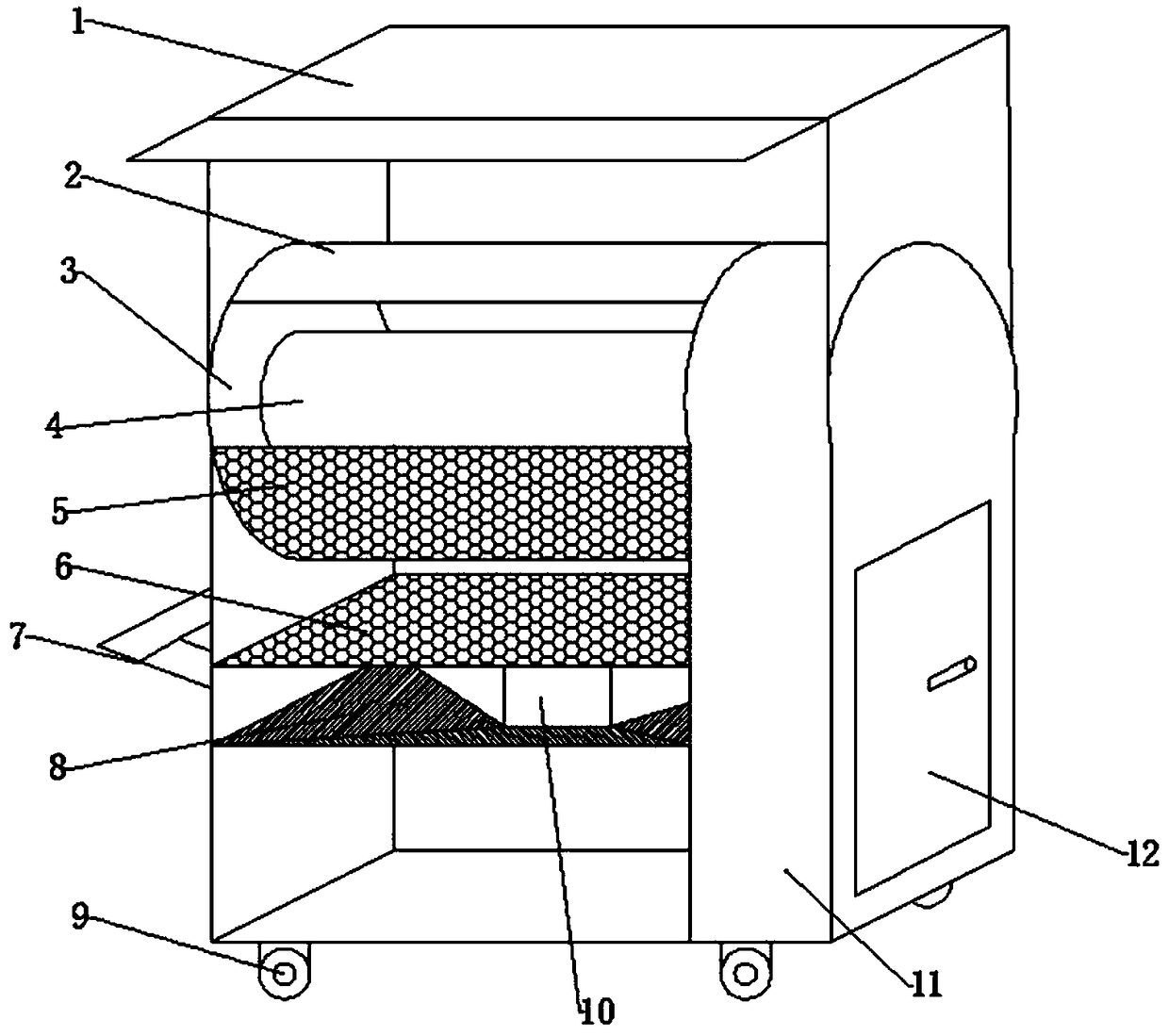

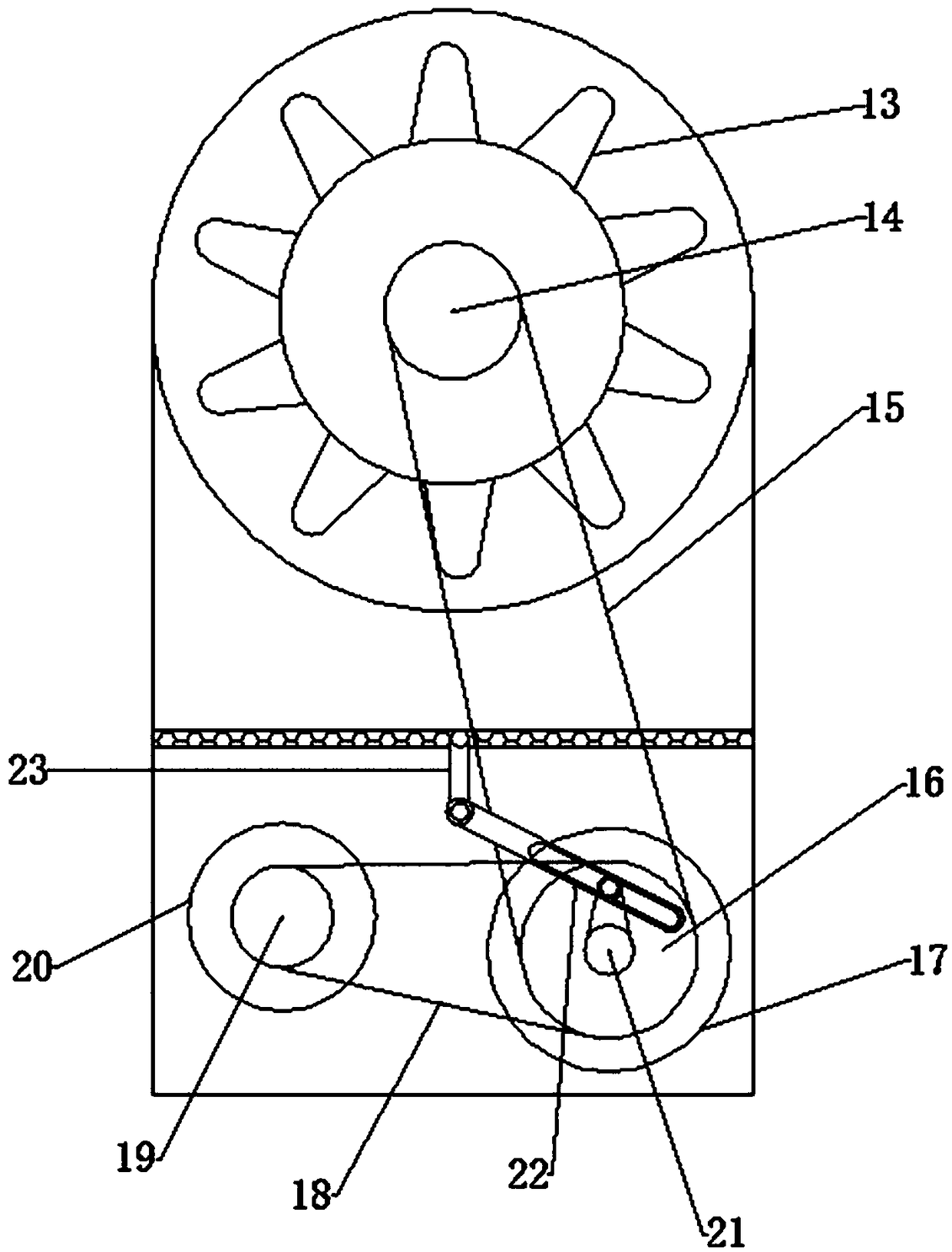

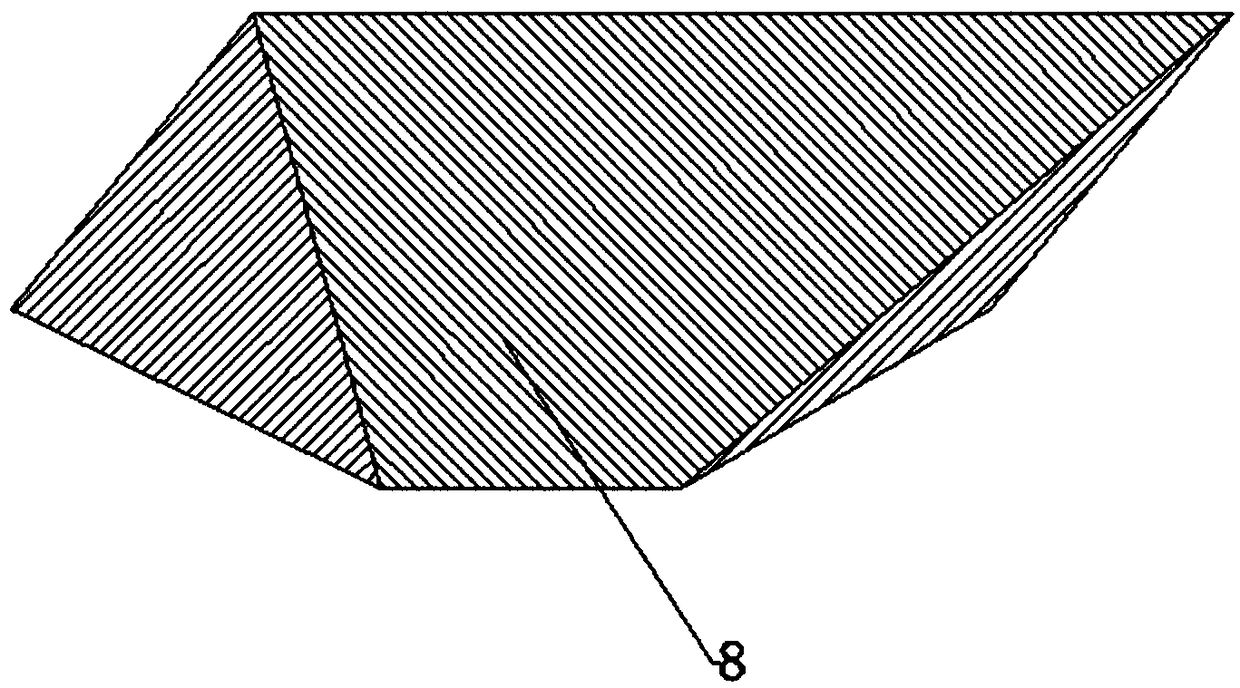

[0019] Example: such as Figure 1-Figure 4 As shown in the figure, a semi-feeding mobile threshing machine for both weather and rain includes a protective cover 1, and a working box 2 is installed under the protective cover 1. In order to ensure the stability of the protective cover 1, bolts are used between the protective cover 1 and the working box 2. connection, the upper end of the working box 2 is provided with a threshing cabin 3, a threshing drum 4 is installed in the threshing cabin, an arc-shaped screen 5 is installed under the threshing drum 4, and a fine screen 6 is installed under the arc-shaped screen 5, in order to make fine Screen cloth 6 can carry out reciprocating motion, and the two ends of fine screen cloth 6 are equipped with pulley, and fine screen cloth 6 is installed on the chute that workbench 2 is provided with, and one side of fine screen cloth 6 is provided with chaff outlet 7, fine screen cloth 6 The bottom of the screen 6 is equipped with a grain h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com