NB-IoT-based automatic lifting trolley case

A technology of automatic lifting and trolley case, which is applied to suitcases, machine-to-machine/machine-type communication services, clothing, etc., can solve problems such as short service life, inconvenient use, and inability to use the automatic lifting function, and achieve low delay , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

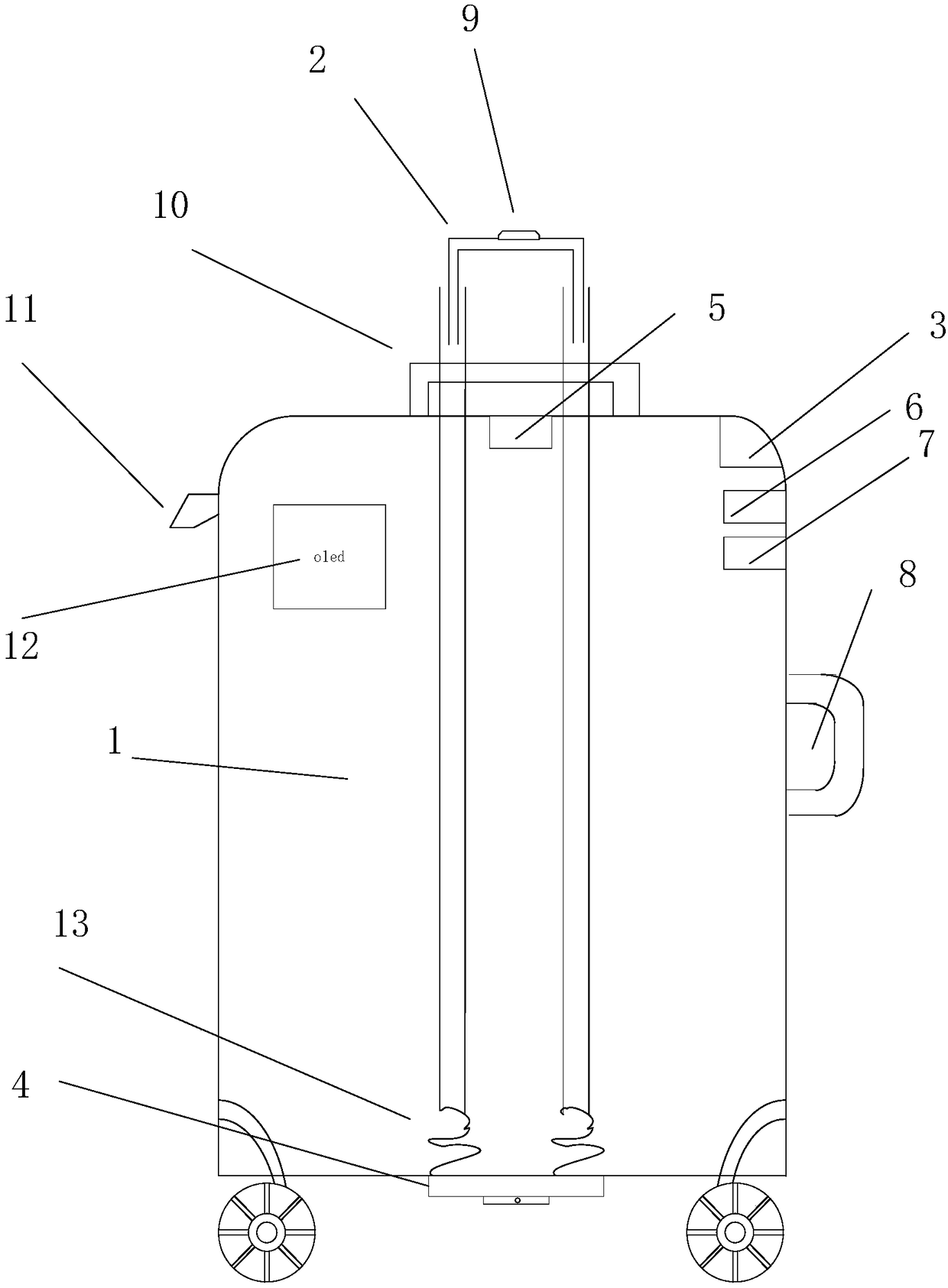

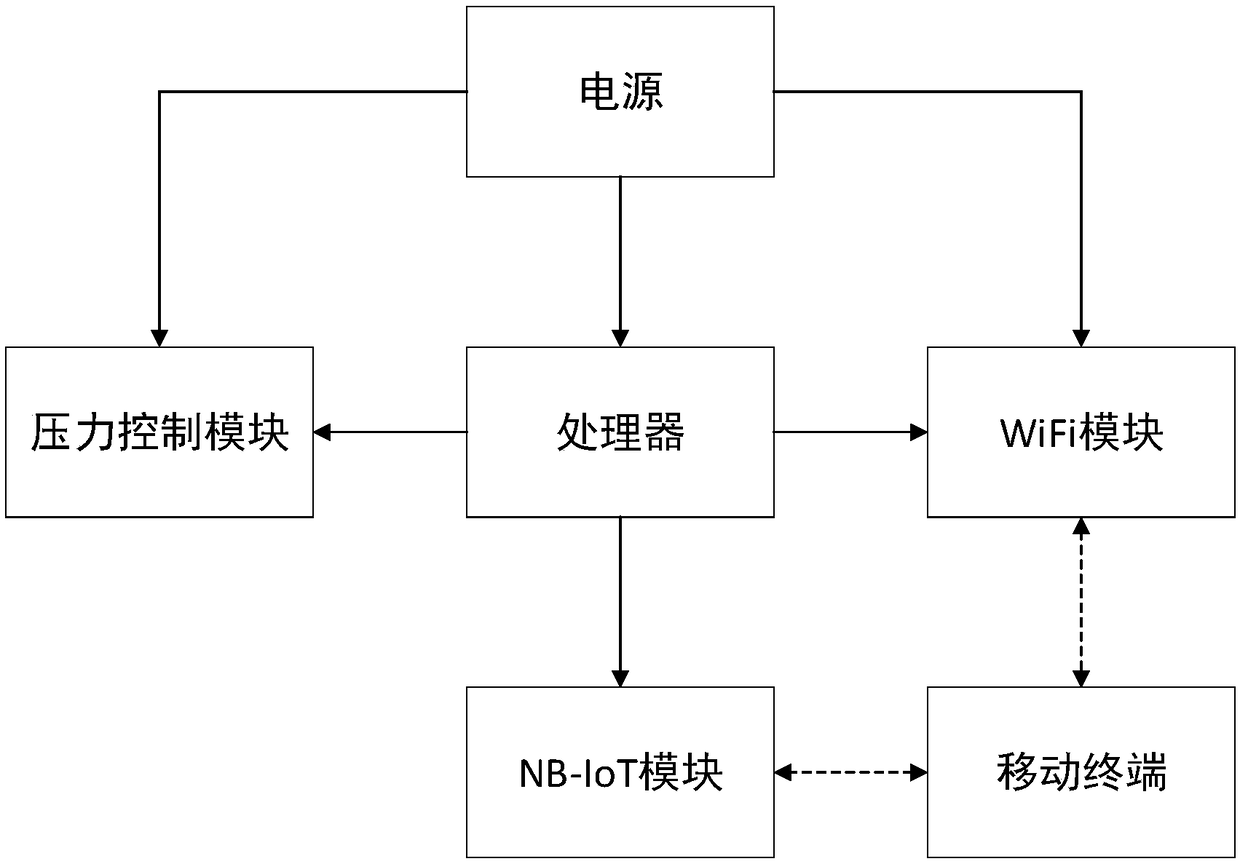

[0015] NB-IoT-based automatic lifting trolley case, such as figure 1 As shown, it includes trolley case body 1, lifting rod 2, processor 3, pressure control module 4, power supply 5, WiFi module 6 and NB-IoT module 7. The bottom of the lifting rod 2 is connected with the bottom of the trolley box casing 1 with a spring 13; figure 2 As shown, the pressure control module 4, power supply 5, WiFi module 6 and NB-IoT module 7 are respectively connected to the processor 3; the processor 3 is used to generate the lifting signal of the lifting rod 2 and send it to the pressure control module 4; Control the rise and fall of the lifting rod 2 by controlling the spring 13 between the bottom of the lifting rod 2 and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com