Hot rolling low-temperature reeling band steel surface purging control method based on water area

A control method and water area technology, applied in temperature control, metal rolling, metal rolling, etc., can solve the problems of increased energy consumption for purging, reduce energy consumption, reduce equipment use costs, and improve temperature measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

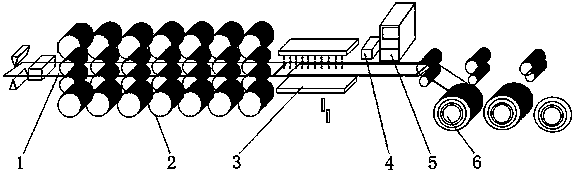

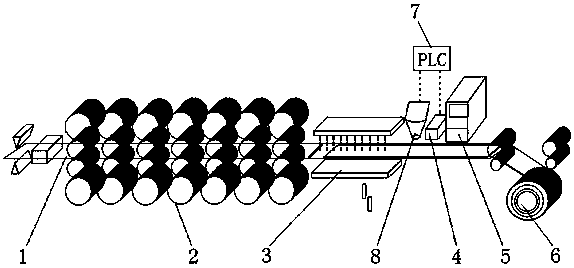

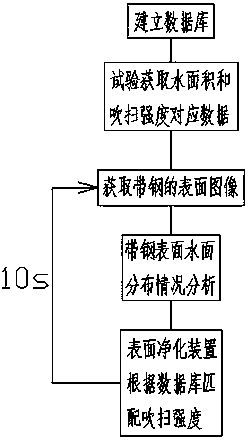

[0030] Such as figure 2 , 3 As shown, a method of purging the surface of the hot-rolled low-temperature coiled steel strip based on the water area, divides the nozzles of the surface cleaning device 4 into several groups, and the air supply pipeline of each group of nozzles is controlled by the purge controller 7 On and off, an imaging device 8 is set between the laminar flow cooling device 3 and the surface cleaning device 4, and then controlled according to the following steps:

[0031] S1. establish water area percentage and purge intensity database, store in the database after obtaining the required purge intensity of strip steel surface in each water area percentage by test;

[0032] Percentage of water area = (residual water area on strip surface / total surface area of strip) × 100%

[0033] Purge intensity = (number of opened nozzle groups / total number of nozzle groups) × 100%;

[0034] S2. The imaging device acquires the surface image of the steel strip and send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com