Steel bar bending device for engineering construction

A technology for engineering construction and bending device, applied in the field of engineering construction, can solve the problems of side slip between the device and the ground, large bending force, large bending range of steel bars, etc., so as to facilitate fixing, increase contact area, and increase friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

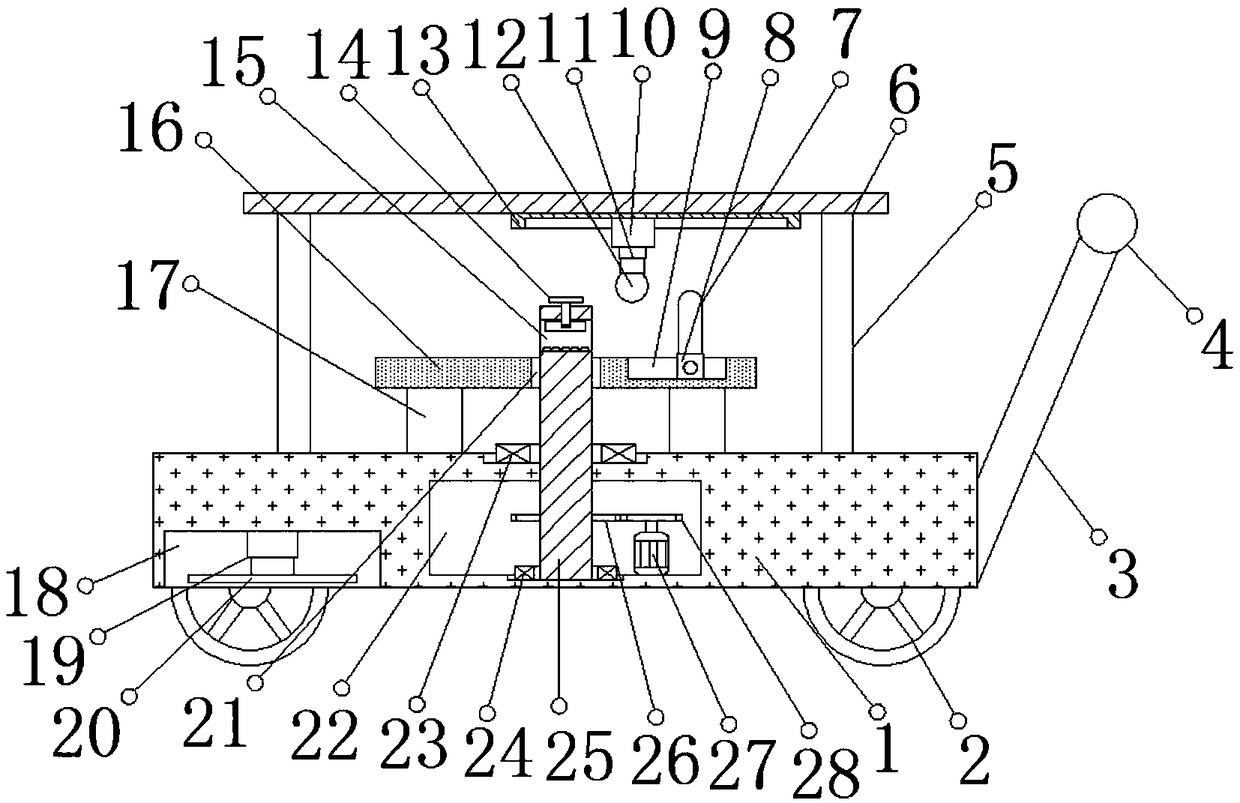

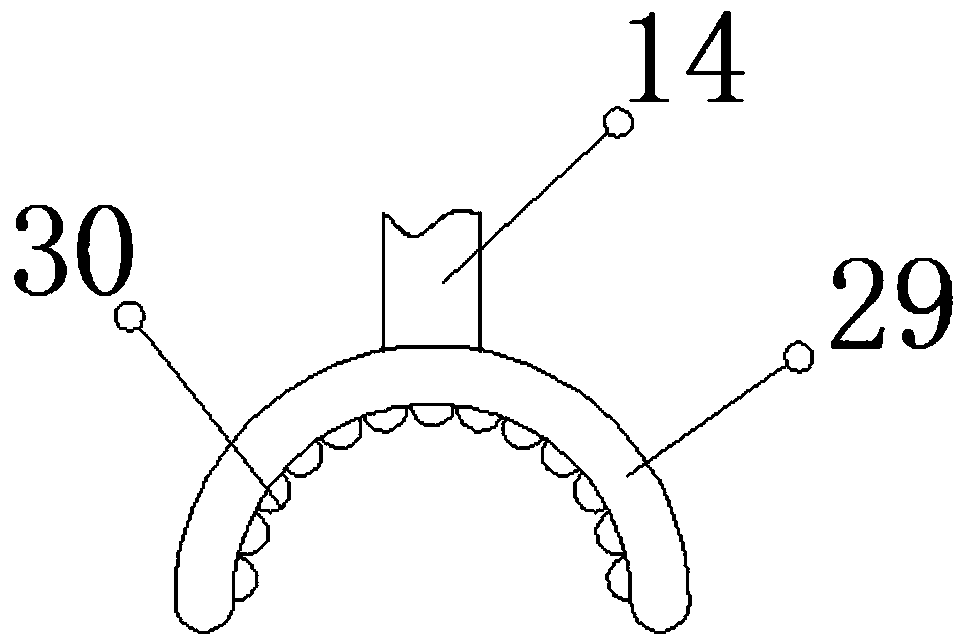

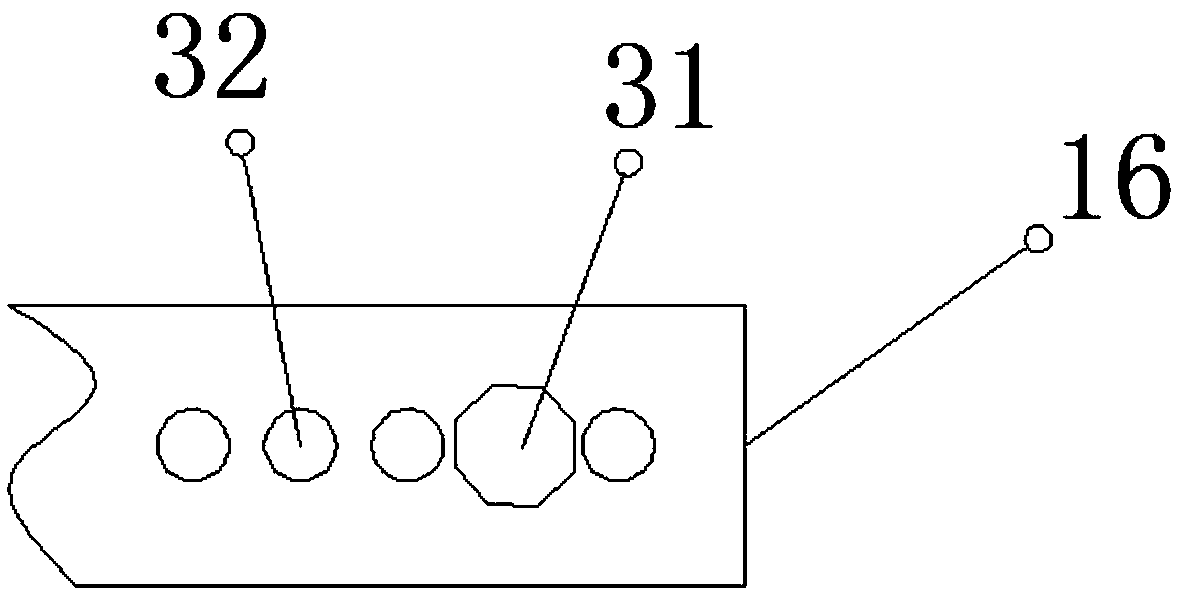

[0028] Reference Figure 1-5 , A steel bending device for engineering construction, comprising a bottom plate 1, the outer walls of both sides of the bottom plate 1 are rotatably connected with moving wheels 2, and the number of moving wheels 2 is four, and both sides of one side of the bottom plate 1 are welded There is a fixed rod 3, and a reinforcing rod 33 is welded on the outer wall of one side of the two fixed rods 3 near the middle. The outer wall of the two fixed rods 3 is connected with a push rod 4 by bolts on the side away from the bottom plate 1, and the push rod A protective sleeve 34 is sleeved on the outer wall of the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com