Coil framework L-shaped terminal pressing-in tool

A coil bobbin, L-shaped technology, applied in the field of press-fitting tooling, can solve the problems of laborious, oblique insertion and bending of L-shaped terminals, and achieve the effects of convenient use, prevention of frictional resistance, and improvement of labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

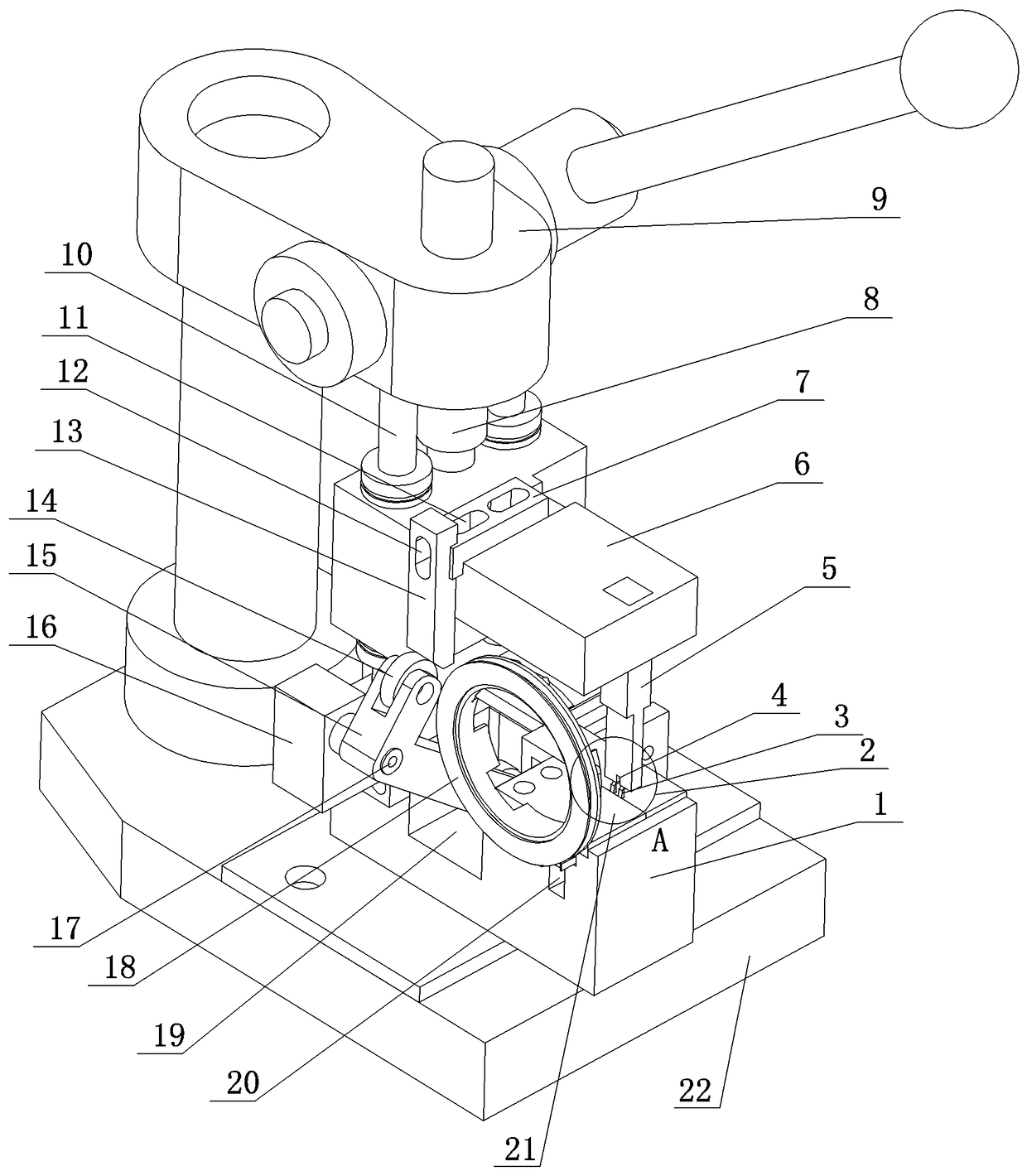

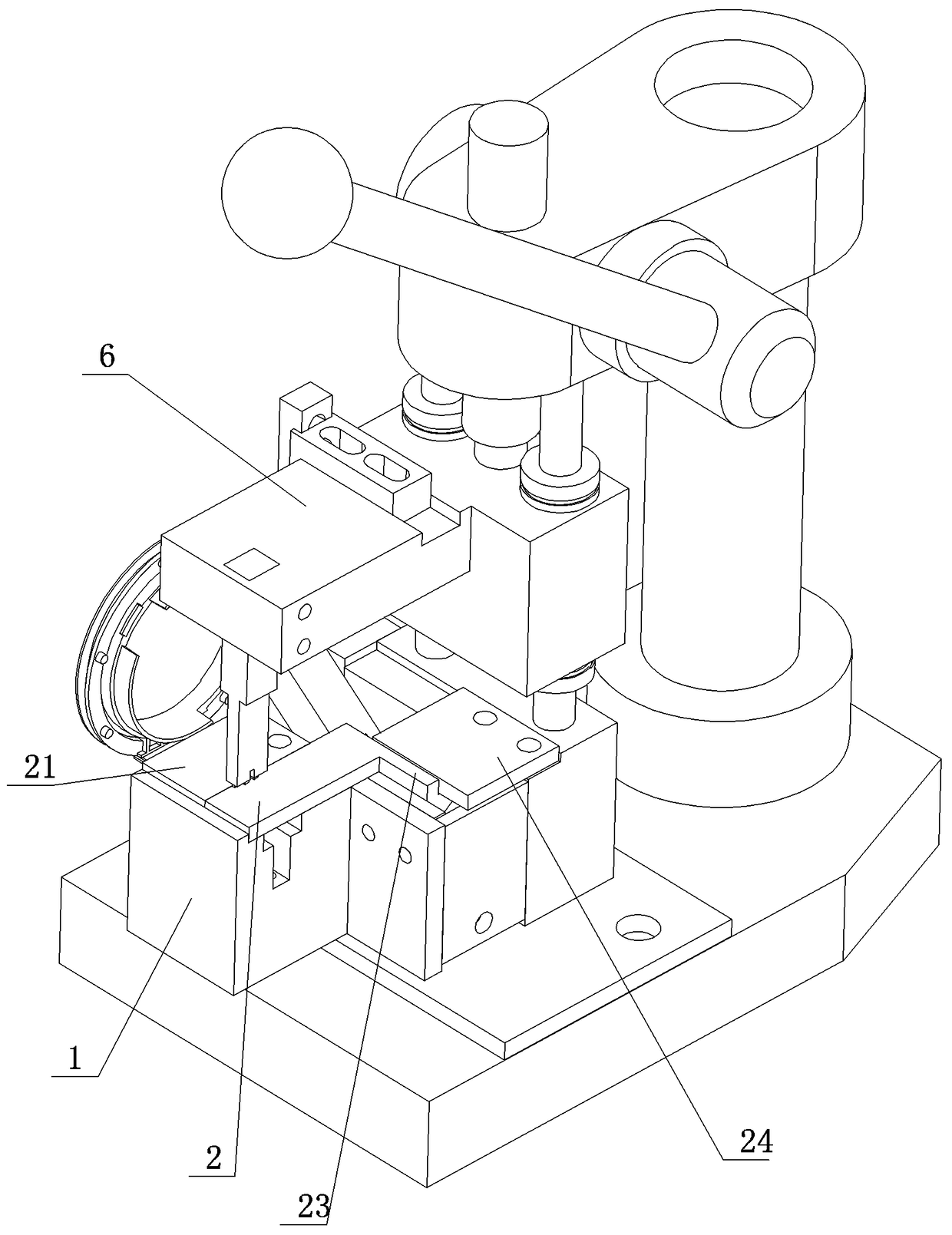

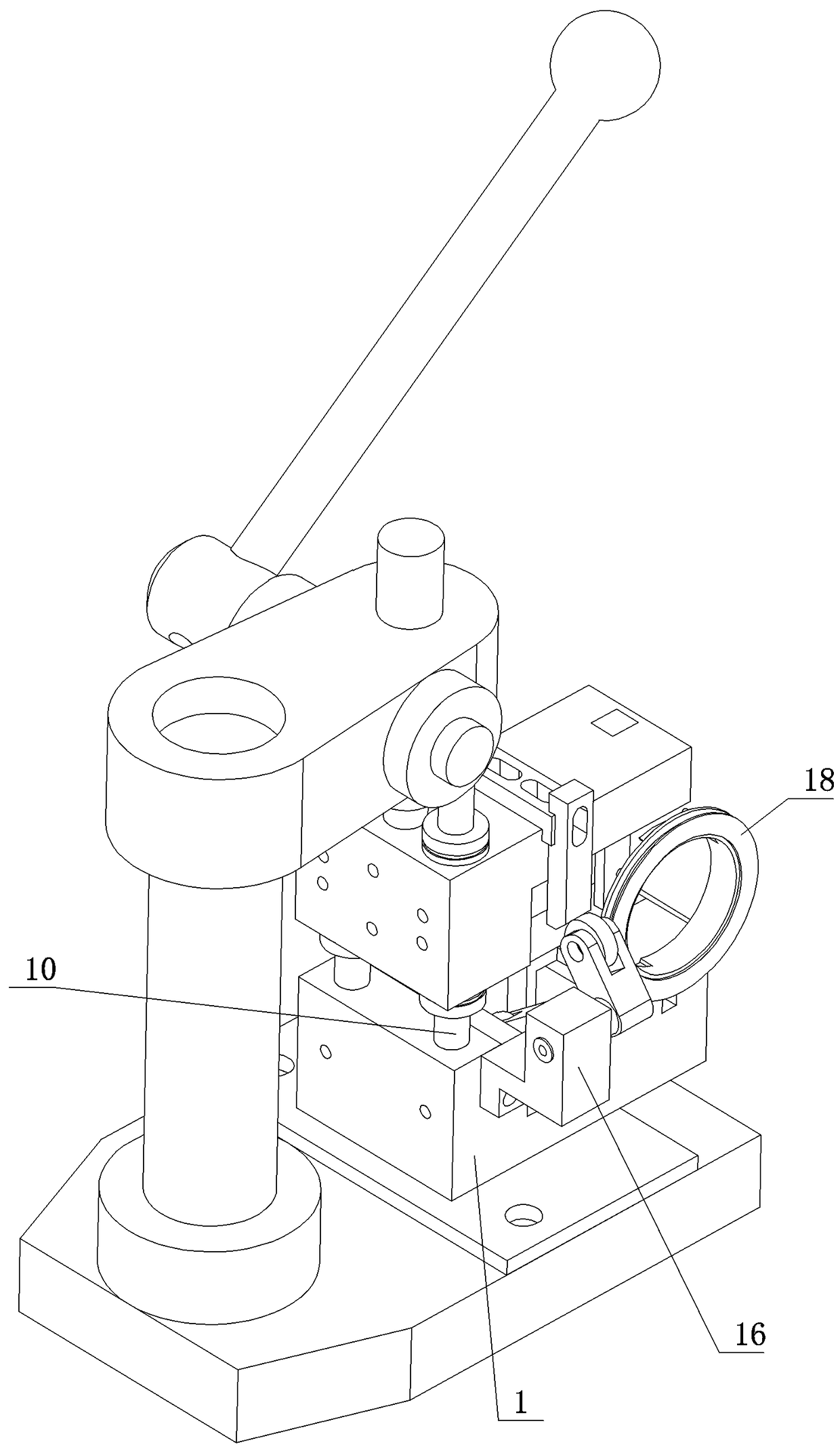

[0041] As shown in the figure, the present invention includes a bottom plate, on which a lower pin block is provided, a pin fixing plate is provided on one side of the upper end of the lower pin block, and a pin moving plate is provided on the other side of the upper end of the lower pin block, and the pin The initial position of the moving plate is connected to the pin fixing plate, and the contact surface between the pin moving plate and the pin fixing plate is provided with an L-shaped terminal insertion slot;

[0042] A horizontal upper plate is arranged above the lower block of the pin, and guide posts are pierced on both sides of the rear end of the upper plate. For the pressing block, the front end of the upper plate is provided with a downwardly extending vertical upward pressing head corresponding to the L-shaped terminal insertion groove, and the lower end surface of the oblique pressing block includes an outer inclined surface inclined from the outside to the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com