Mechanical clamping device

A technology of mechanical clips and mechanical grippers, applied in the field of gripping devices, can solve the problems of inconvenient application, cost waste, cost increase of mechanical arms, etc., and achieve the effects of novel design, convenient use, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

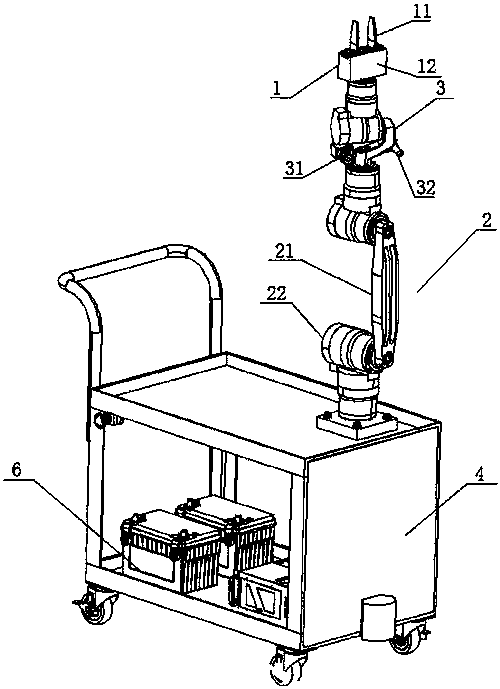

[0019] Such as figure 1 As shown, a kind of mechanical clamping device comprises mechanical gripper 1, mechanical arm 2, positioning mechanism 3 and movable platform 4, and described mechanical arm 2 is installed on movable platform 4, and described mechanical arm 2 is composed of power arm 21 and The sensor 22 is composed of six sensors. Under the action of the power arm 21 and the sensor 22, the mechanical arm realizes a 360° random rotation movement and realizes the flexibility of movement. In order to facilitate the grabbing of objects during the construction process, the mechanical gripper 1 is fixedly mounted on the end of the mechanical arm 2 and is detachable. The mechanical gripper 1 includes a fork claw 11 at the front end and a fixed end 12 at the rear end. There are two fork claws 11. The two fork claws 11 move across each other to realize the grasping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com