Cutting device for excess materials of plastic products

A technology of cutting device and plastic products, applied in metal processing and other directions, can solve the problems of unfavorable collection of waste and waste of labor, and achieve the effect of good continuity and reduced purchase cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

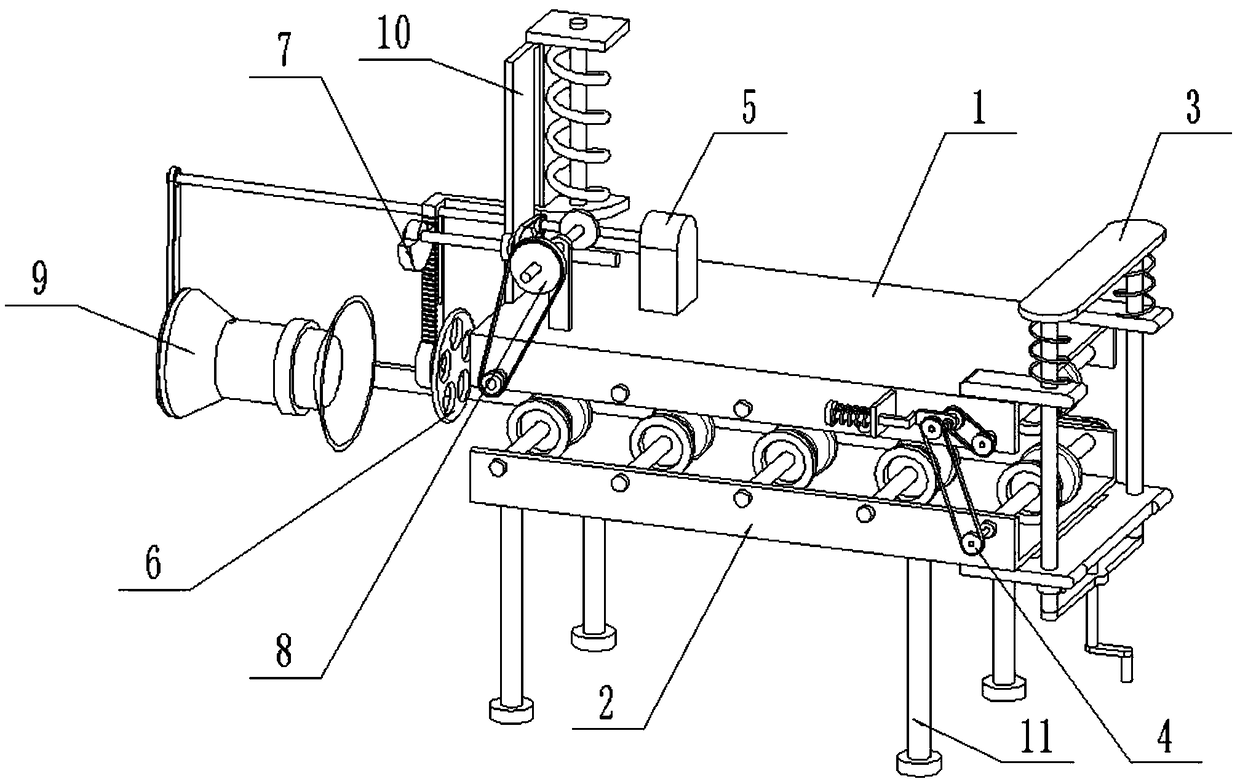

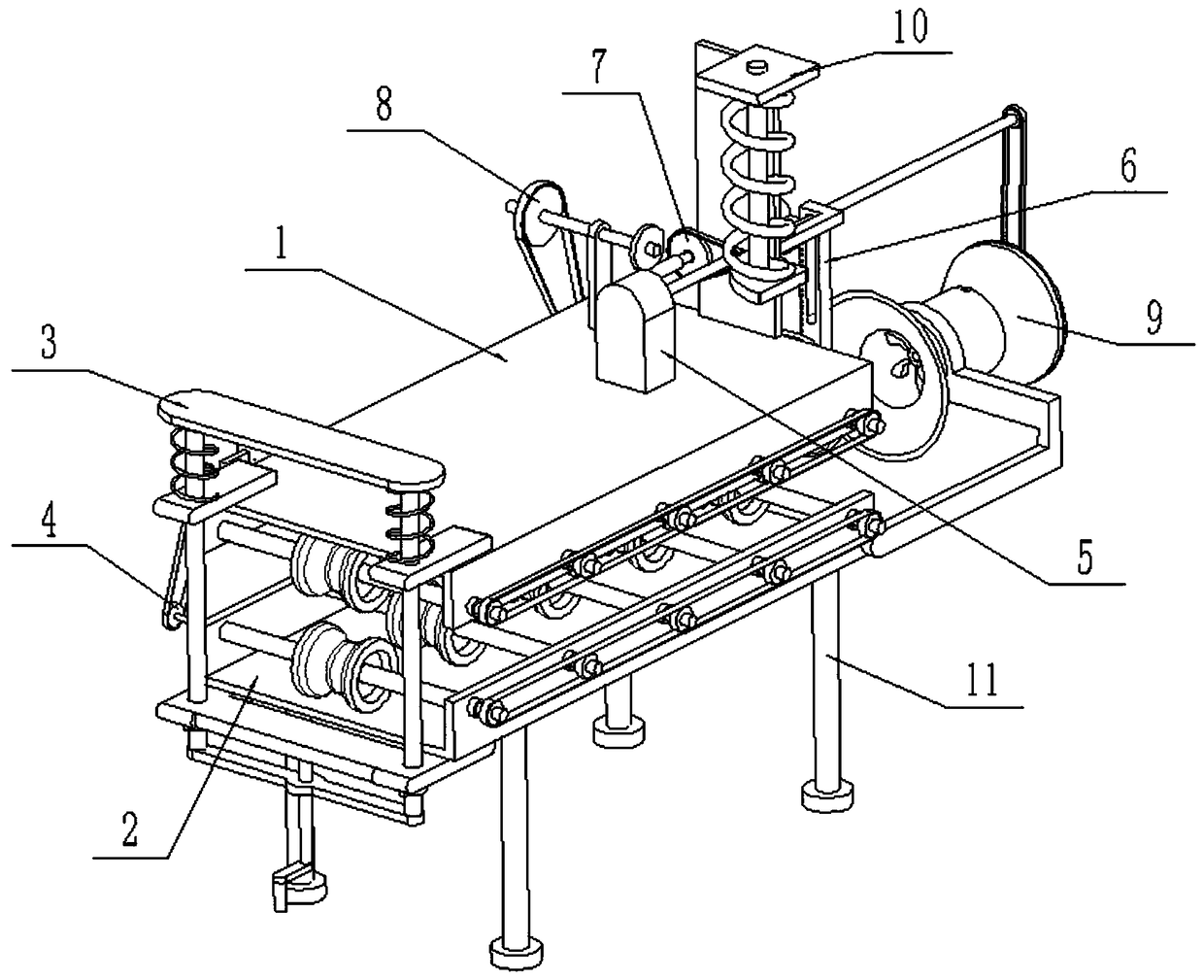

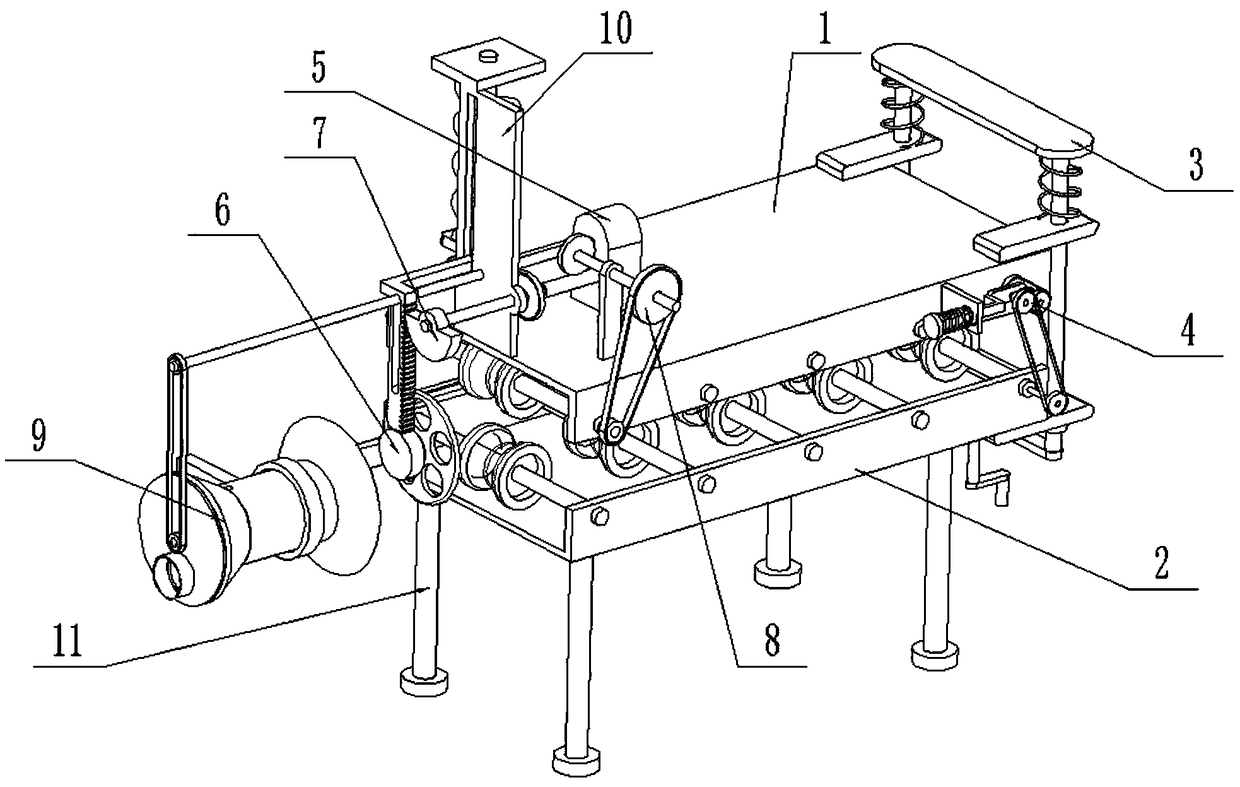

[0035] Such as Figure 1-14 As shown, a cutting device for excess material of plastic products includes an upper feeding table 1, a lower feeding table 2, a vertical adjustment frame 3, a tension linkage wheel 4, a driving mechanism 5, an excess material cutting knife 6, an elevating transmission wheel 7, a speed change Transmission wheel 8, debris collector 9, vertical frame plate 10 and support leg 11, the right end of described upper feeding table 1 is fixedly connected with the upper end of vertical adjustment frame 3, and the lower end of vertical adjustment frame 3 is fixedly connected with lower feeding table 2; Each of the four corners at the bottom of the lower feeding table 2 is fixedly connected with a support leg 11; 4. The transmission is connected to the lower feeding platform 2; when in use, the drive mechanism 5 and the surplus material cutting knife 6 are respectively connected to the power supply through a wire and turned on by a control switch, the drive mec...

specific Embodiment approach 2

[0037] Such as Figure 1-14 As shown, the upper feeding platform 1 includes an upper mounting frame 1-1, an upper feeding pressure roller 1-2, an upper roller shaft 1-3, an upper linkage sprocket 1-4 and an upper linkage chain 1-5; There are multiple roller shafts 1-3, and the multiple upper roller shafts 1-3 are rotatably connected to the upper mounting frame 1-1 through bearings with seats from left to right, and the middle ends of the multiple upper roller shafts 1-3 are fixedly connected. One upper feeding pressure roller 1-2; the rear ends of multiple upper roller shafts 1-3 are each fixedly connected to an upper linkage sprocket 1-4, and the upper linkage chains 1-5 are used for transmission between multiple upper linkage sprockets 1-4 Connection; the drive motor 5-1 is fixedly connected to the top of the upper mounting frame 1-1; the vertical frame plate 10 is fixedly connected to the left side of the top of the upper mounting frame 1-1. When the upper feeding table 1 ...

specific Embodiment approach 3

[0038] Such as Figure 1-14 As shown, the lower feeding platform 2 includes a lower mounting frame 2-1, a lower feeding pressure roller 2-2, a lower roller shaft 2-3, a lower linkage sprocket 2-4 and a lower linkage chain 2-5; There are multiple roller shafts 2-3, and the multiple lower roller shafts 2-3 are rotatably connected to the lower mounting frame 2-1 through bearings with seats from left to right, and the middle ends of the multiple lower roller shafts 2-3 are respectively fixed. Connect a lower feeding pressure roller 2-2; the rear ends of multiple lower roller shafts 2-3 are each fixedly connected to a lower linkage sprocket 2-4, and the lower linkage chain 2-4 is passed between multiple lower linkage sprockets 2-4 5 transmission connection; a plurality of lower feeding pressure rollers 2-2 and a plurality of upper feeding pressure rollers 1-2 are arranged oppositely, and the roller surfaces of the lower feeding pressure rollers 2-2 and the upper feeding pressure ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap