Isostatic pressing forming method of ceramic inner container and die of ceramic inner container

A technology of isostatic pressing and ceramic pots, which is applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of low pass rate, inconsistent product size, strong green body and low density, and achieve productivity and product pass rate Improvement, uniform internal density, high green body density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] Specific implementation plan

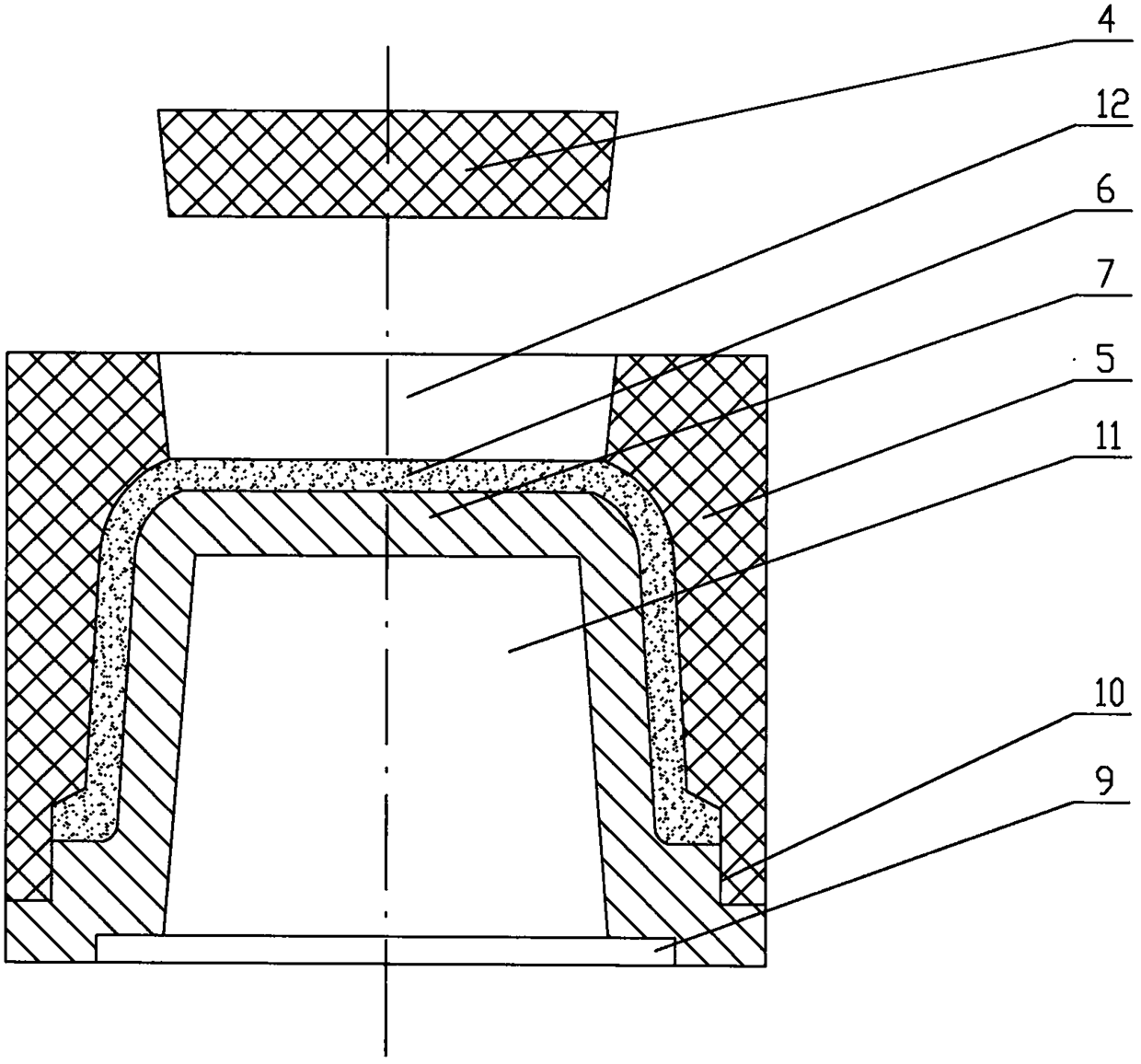

[0013] Such as figure 2 The isostatic pressure forming ceramic pot mold shown in is to tightly sleeve the rubber or polyurethane outer mold 5 at the positioning step 10 of the metal mold core 7, and hollow out the center of the mold core to reduce the weight of the metal mold core 7. 11. Of course, it can also be solid without hollowing out. Remove the rubber or polyurethane bottom mold 4, and add the granulated ceramic powder 6 from the outer mold feed port 12 to the gap between the rubber or polyurethane outer mold 5 and the metal core 7 that is the cavity, and place the upper part The ceramic powder 6 is flattened, and then the rubber or polyurethane bottom mold 4 is plugged into the outer mold feeding port 12, and the filling is completed by plugging. The filled isostatic pressing ceramic pot forming mold can be pressed into a dry bag isostatic press or a traditional wet bag isostatic press.

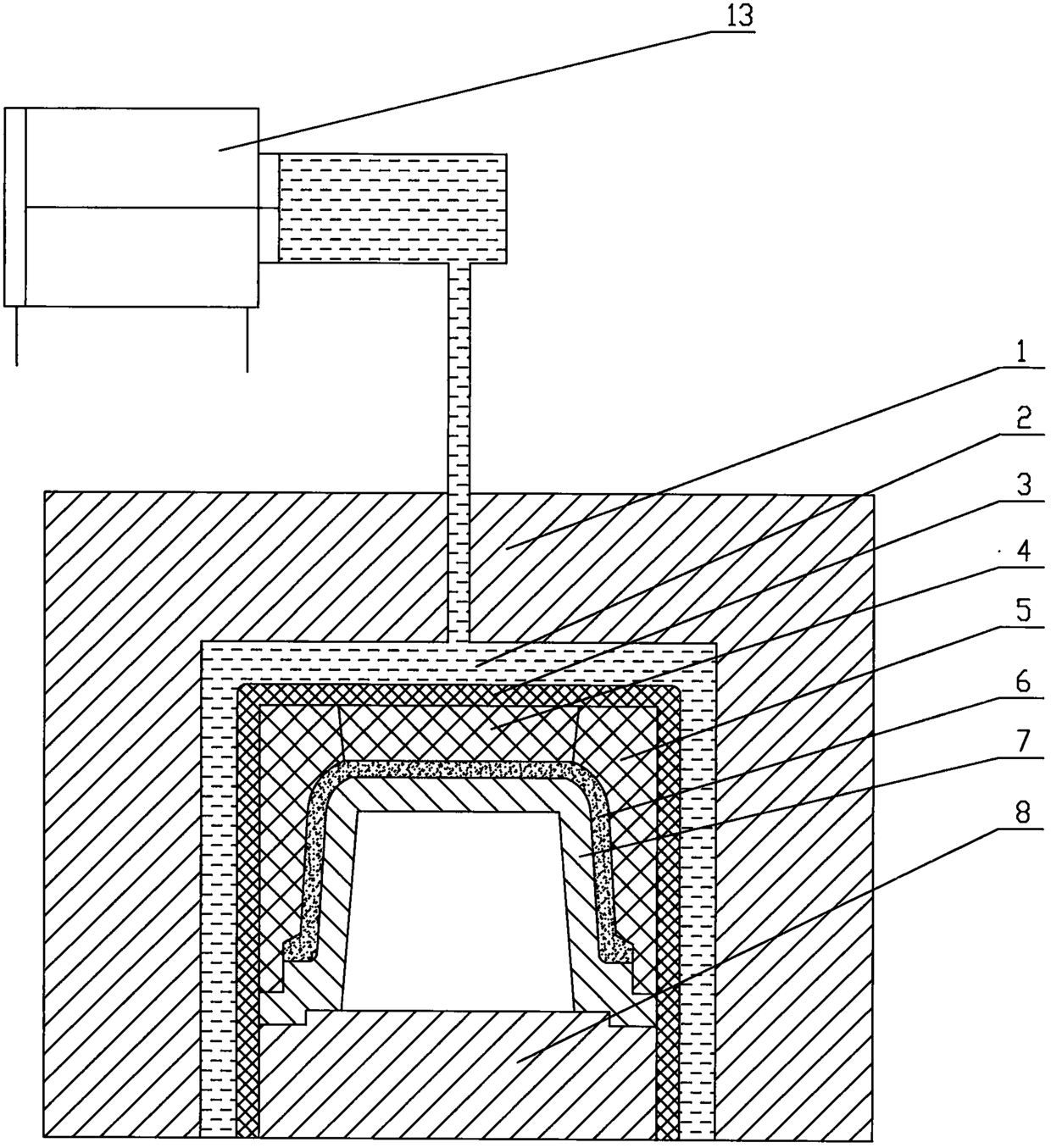

[0014] Such as figure 1 As shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com