A kind of preparation method of airgel composite material

A composite material and aerogel technology, applied in the field of composite materials, can solve the problems of inability to integrally form large-thickness products, limited thickness of aerogel composite materials, poor adjustability of aerogel thickness, etc. Layers or cracks, thickness can be adjusted, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Preparation of an airgel composite material with a thickness of 500mm*500mm*30mm

[0043] Preparation:

[0044] (1) Forming tooling design: design the airgel forming tooling according to the product size, set 5 glue discharge ports on the upper and lower molds of the forming tooling, and design a glue inlet around the middle frame of the forming tooling;

[0045] (2) Fiber matrix mold closing: put the quartz fiber matrix with a thickness of 30mm into the forming mold to ensure that the forming mold is well airtight;

[0046] (3) Dipping molding: connect the pipeline, start pre-vacuuming, after the vacuuming time is 15 minutes, import the prepared glue into the glue injection tank, and start vacuum glue injection, the glue injection time is 5 minutes, and the vacuum injection time is 5 minutes. The amount of glue is 3000L; after that, the second vacuuming is started, the vacuum time is 5min, and the soaking time is 5min; after that, the pressure injection of ...

Embodiment 7

[0053] The preparation method and process of this embodiment are basically the same as in Example 1, except that in the dipping molding process, there is only one pressure application process and pressure holding process, and the dipping molding process is as follows:

[0054] Connect the pipeline and start pre-vacuuming. After the vacuuming time is 15 minutes, import the prepared glue into the glue injection tank, and start vacuum glue injection. The glue injection time is 5 minutes, and the glue discharge volume during vacuum injection is 3000L; after that Start the second vacuuming, the vacuum time is 5min, and the impregnation time is 5min; then start the pressure injection of 0.1MPa, the pressure holding time is 5min, the first discharge volume is 7500L, and finally the wet gel is obtained.

experiment example

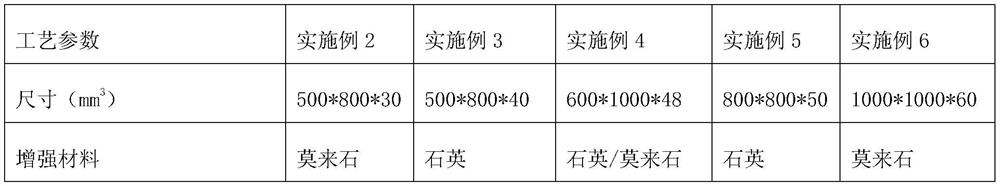

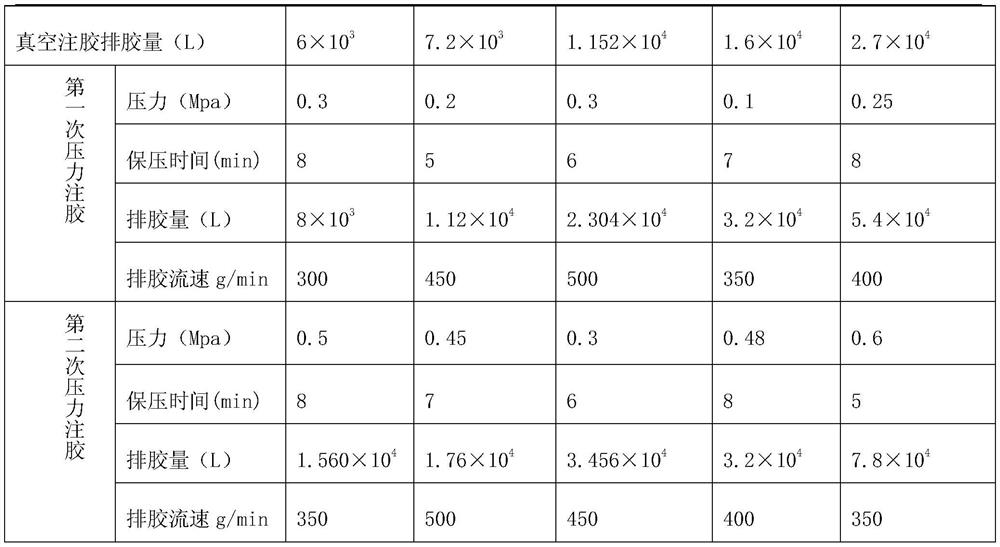

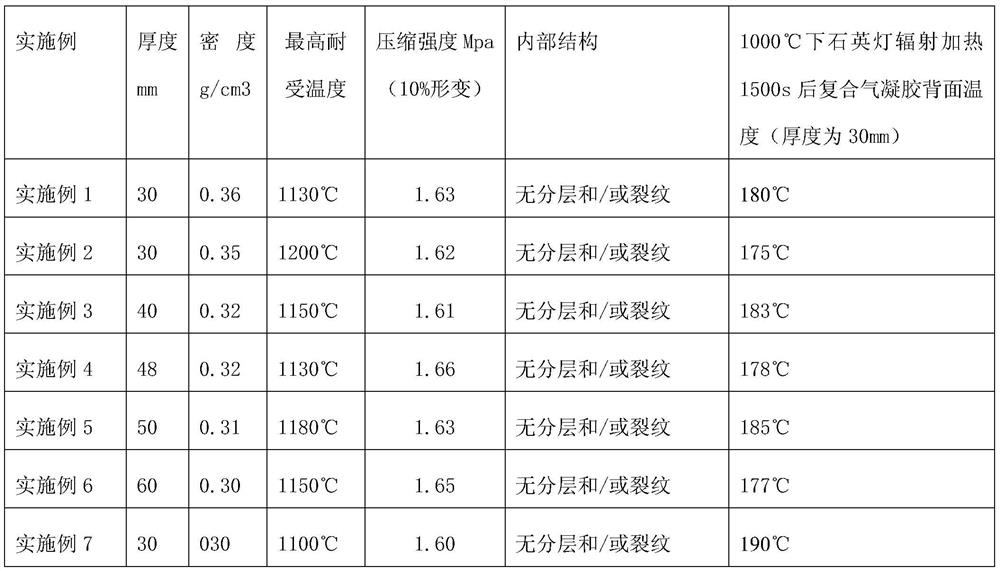

[0067] This experimental example is a performance comparison between the airgel composite materials prepared in Examples 1-7 and the airgel composite materials prepared in Comparative Examples 1 and 2. The results are shown in Table 2.

[0068] Table 2:

[0069]

[0070]

[0071] As can be seen from the above experimental results, compared with Comparative Example 1-2, the airgel composite material prepared in Example 1-7 has higher density, higher temperature resistance and greater compressive strength, and its internal density uniformity is good. No delamination and / or cracking occurred. However, both comparative example 1 and comparative example 2 are directly vacuum injected without pressure injection process, and their performance in all aspects is poor, and because of the vacuum injection of comparative example 1 has a certain amount of glue discharge, the internal density uniformity is poor , a small amount of delamination and / or cracks appeared, and the uniformi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com