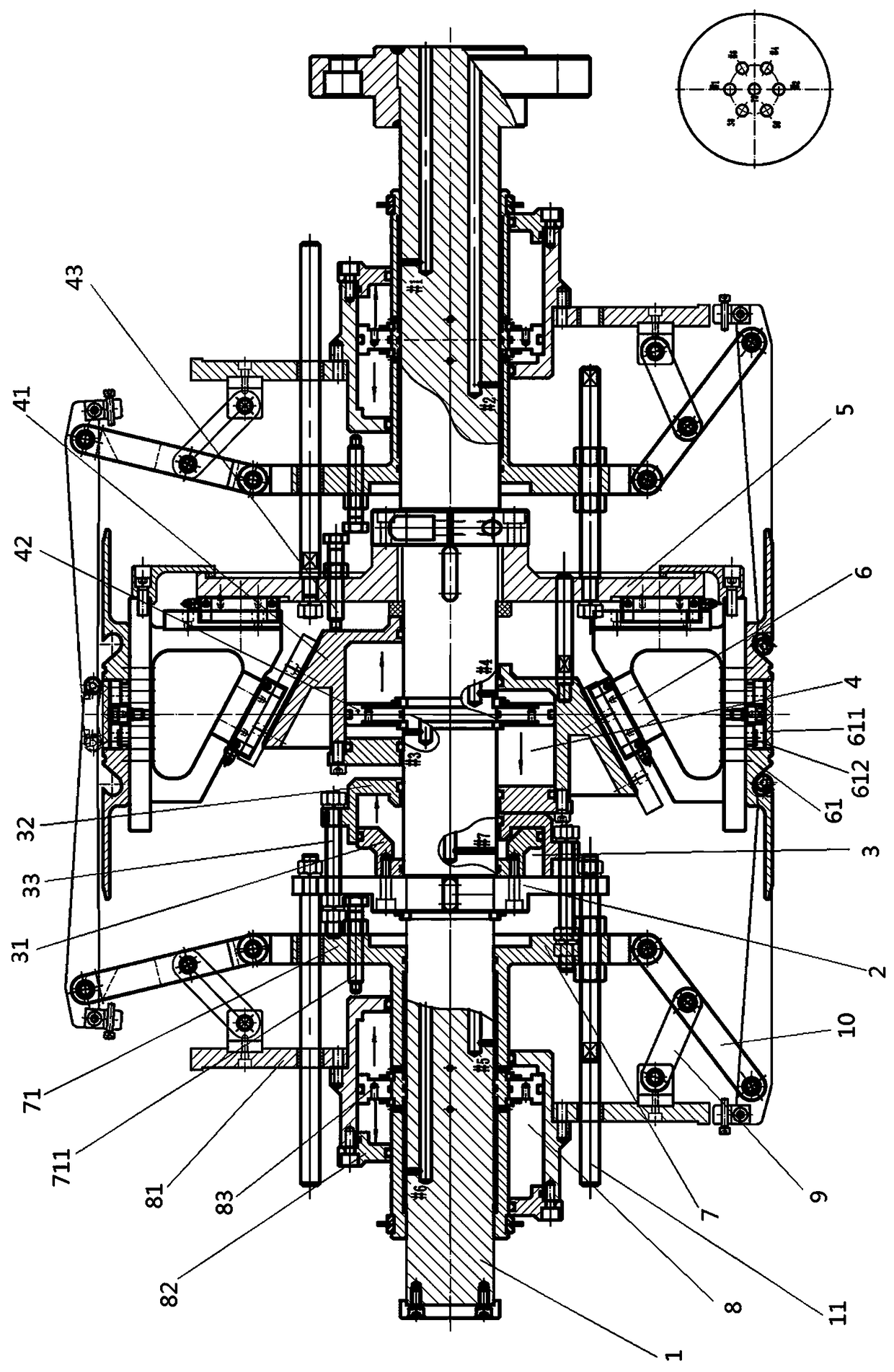

Two-time radial expanding-type shaping drum

A radial expansion and forming drum technology, which is applied in the field of secondary radial expansion forming drums, can solve the problems of heavy drum body weight, non-adjustable drum expansion twice, and poor synchronization of drum tiles, so as to reduce failure rate and inertia Small, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] As shown in the figure: a secondary radial expansion forming drum, including a horizontally placed main shaft 1, an adjustable outer turn-up mechanism distributed on the main shaft 1 from left to right, a positioning disc 2, and an adjustable primary expansion drum Cylinder 3, adjustable secondary drum expansion cylinder 4, limit block 5, adjustable inner turn-up mechanism, the outside of the adjustable secondary drum expansion cylinder 4 is provided with a drum tile bracket 6, and the drum tile bracket 6 The inner side of the inner side is an inclined vertebral surface and forms a sliding connection with the adjustable secondary expansion drum cylinder 4, and the right side of the drum tile bracket 6 forms a sliding connection with the limit block 5, and the drum tile bracket 6 is connected between the limit block 5 and the The adjustable secondary drum expansion cylinder 4 makes radial movement, and the outer drum tile bracket 6 is fixed with a drum tile 61; the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com