Clamping mechanism and terminal CCD detection packing machine provided with same

A clamping mechanism and clamping piece technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of reducing clamping efficiency and adverse CCD detection efficiency, and achieve the goal of improving clamping speed and improving detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

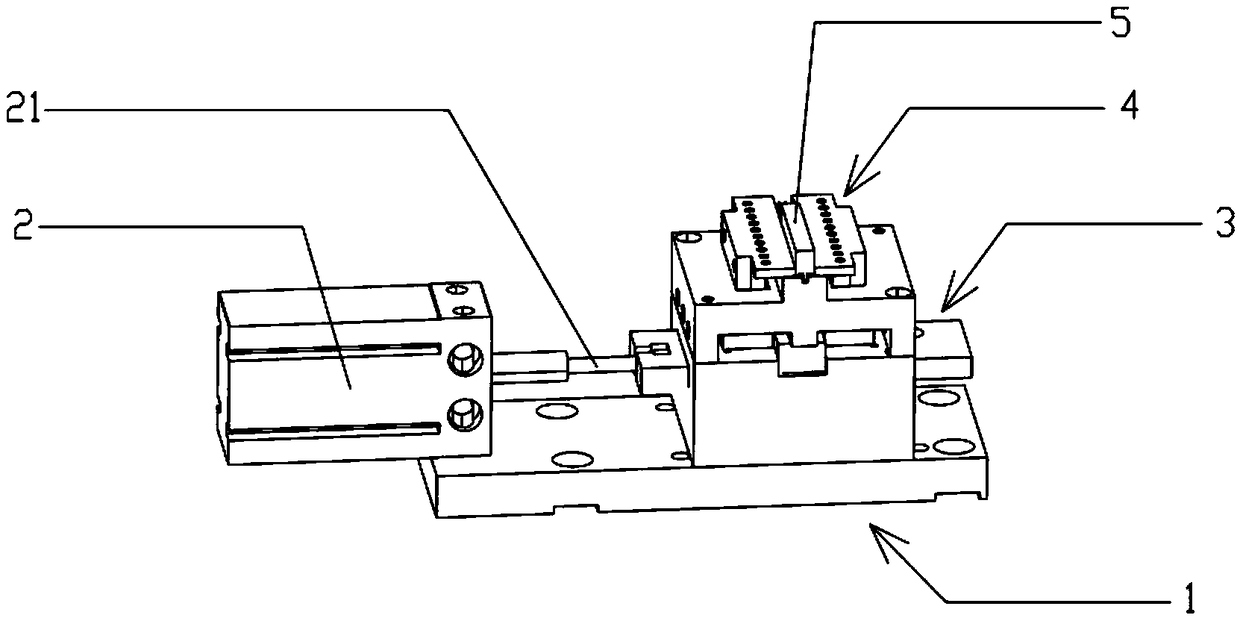

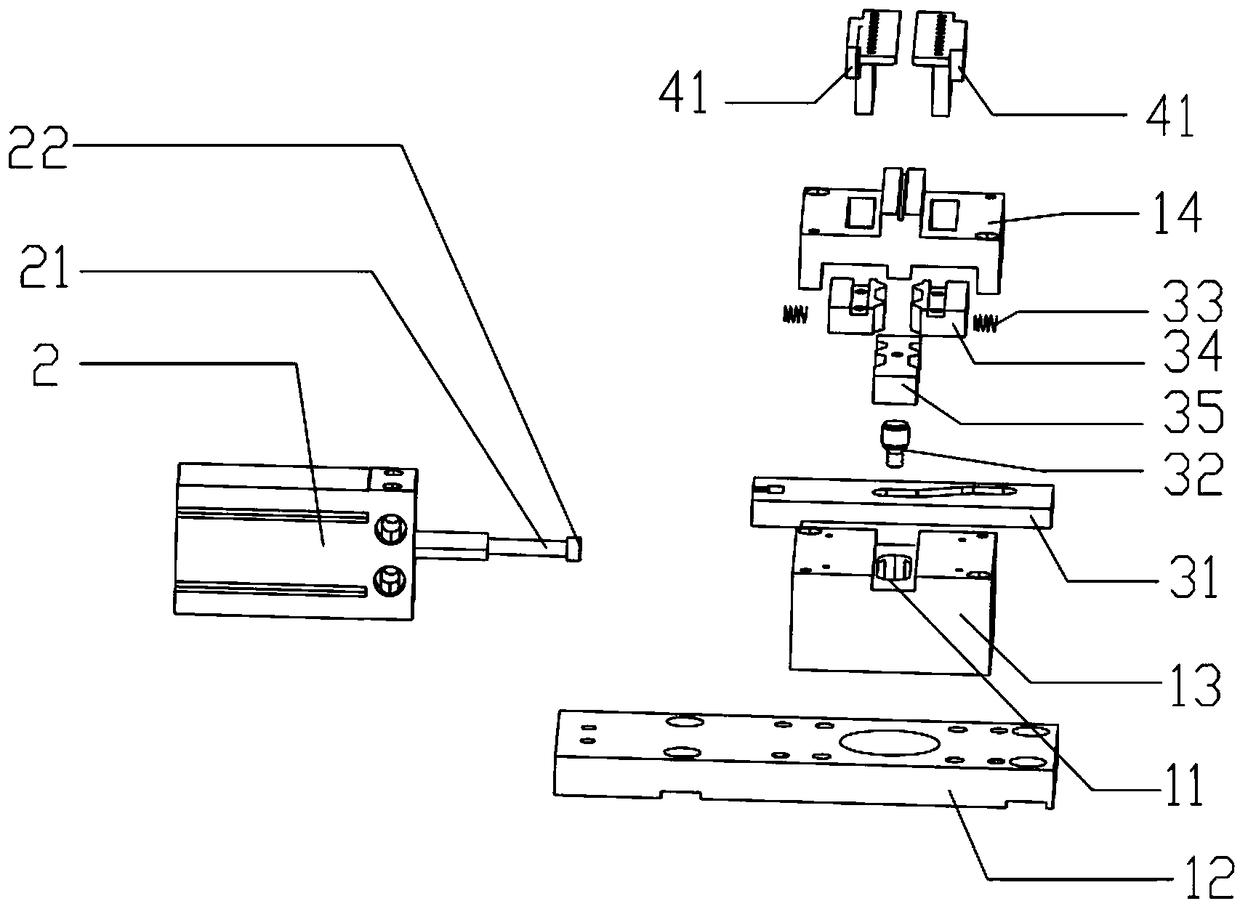

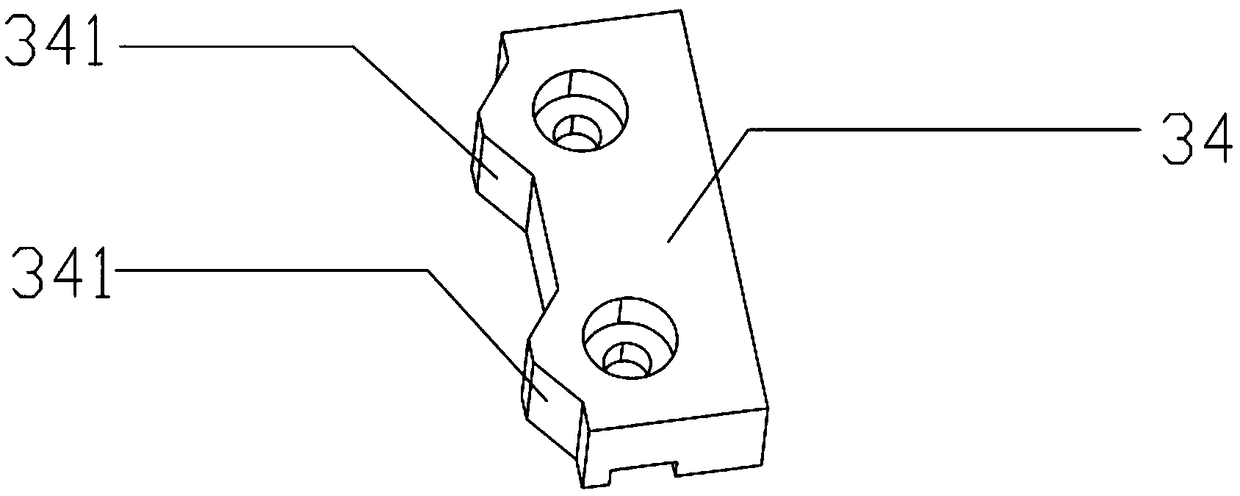

[0031] like figure 1 As shown, a clamping mechanism provided in this embodiment includes a base 1, the base 1 is provided with a cylinder 2, a transmission mechanism 3 and a clamping assembly 4, and the transmission mechanism 3 is arranged on the base 1 Specifically, the transmission mechanism 3 is movably plugged into the base 1; the clamping assembly 4 is arranged on the top of the base 1; the cylinder 2 is controlled by the transmission mechanism 3 The clamping assembly 4 is opened or closed.

[0032] The invention is installed in a terminal CCD detection packaging machine for positioning the terminals. When the present invention performs the clamping action, the piston rod 21 of the cylinder 2 retreats, and the transmission mechanism 3 drives the clamping assembly 4 to close. At this time, the product 5 slides into the clamping assembly 4 from the gap of the clamping assembly 4. At this time The terminal can only move along the direction of sliding into the clamping asse...

Embodiment 2

[0045] like Figure 9 As shown, a kind of CCD detection packaging machine provided in this embodiment includes a frame 6, and the frame 6 is provided with a feeding mechanism 7, a clamping mechanism, a feeding manipulator 8, a CCD detection mechanism 9 and a packaging mechanism 10; the product 5 is transferred to the clamping mechanism by the feeding mechanism 7, and the product 5 is clamped from the clamping mechanism to the CCD detection mechanism 9 by the feeding manipulator 8 for detection, and then the packaging mechanism 10 The tested product 5 is packaged; the clamping mechanism 4 is the above-mentioned clamping mechanism. Specifically, the clamping mechanism is arranged between the feeding mechanism and the CCD detection mechanism, and the feeding mechanism 7, the feeding manipulator 8, the CCD detection mechanism 9 and the packaging mechanism 10 described in this embodiment are all commonly used on the market. structure, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com