Automatic butting and automatic detaching device for crane

An automatic docking and crane technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of easy decoupling of hooks, and achieve the effect of increasing stability, saving manpower and facilitating connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

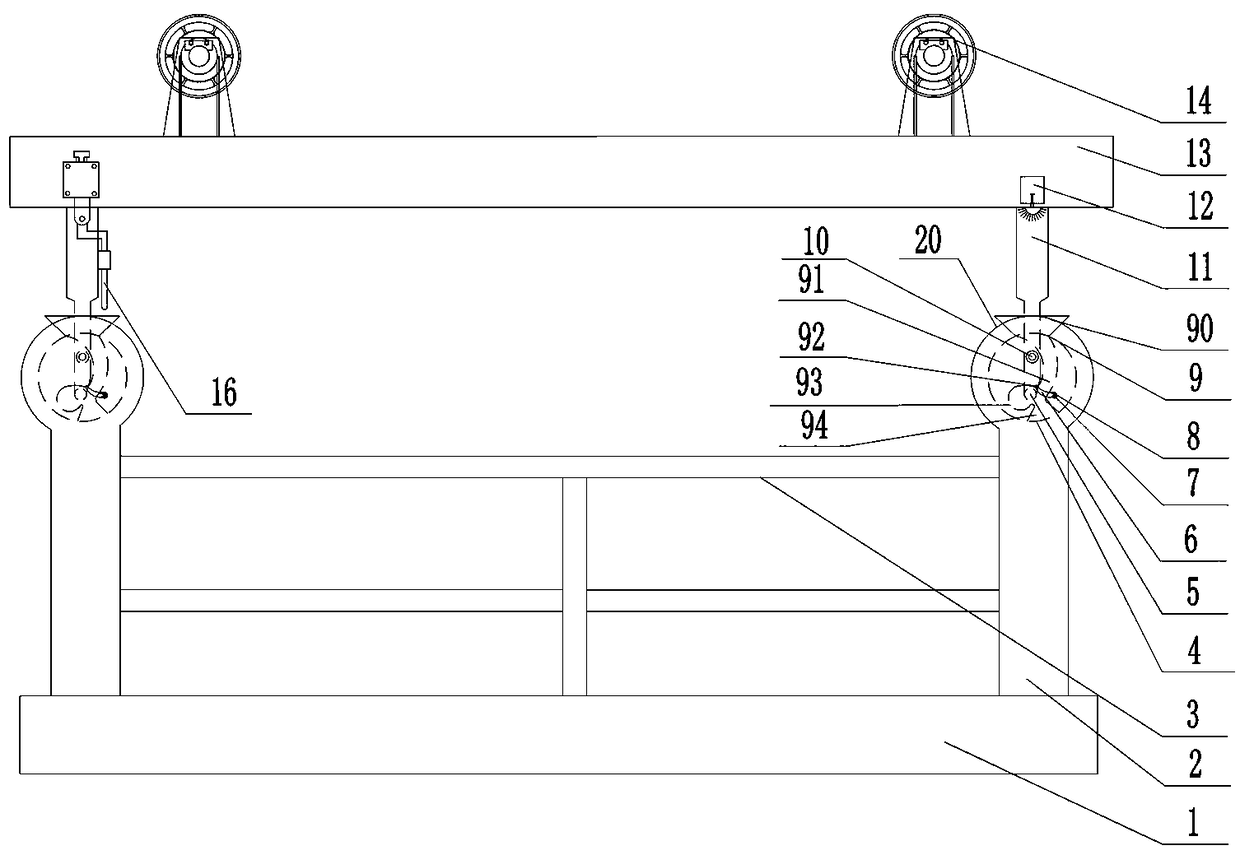

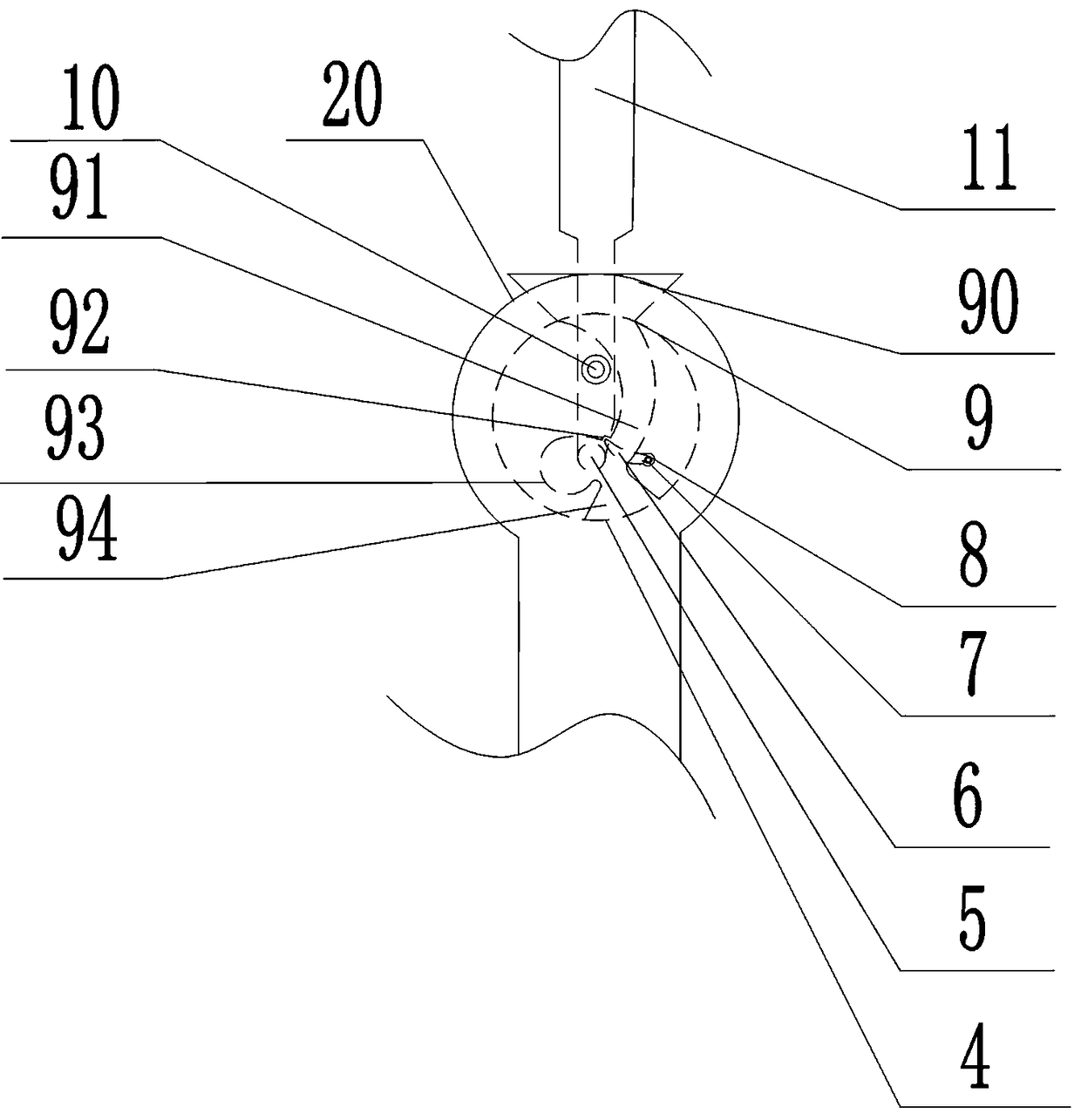

[0018] Such as figure 1 and figure 2 As shown, a kind of automatic docking automatic unhooking device for crane, comprises shelf and spreader 13, is provided with hanger bar 11 at the bottom of spreader 13, is provided with symmetrically arranged horizontal shaft 10 on the top of shelf, and horizontal shaft 10 can be symmetrically arranged about the center of the shelf or the center line. The number of horizontal rotating shafts 10 corresponds to the number of booms 11. On the horizontal rotating shaft 10, an inner disc 4 is eccentrically arranged, and the inner disc 4 rotates with the horizontal rotating shaft 10. Connected, the inner disc 4 is provided with a drive slot 9 on the side close to the shelf, and the drive slot 9 rotates with the inner disc 4 around the horizontal shaft 10, and the side of the inner disc 4 near the shelf refers to the inner disc 4. 4 and the side between the shelf, the notch of the drive slot 9 points to the shelf, the drive slot 9 is sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com