Lifting device for vertical transport

A hoisting device and vertical transportation technology, which is applied to cranes and other directions, can solve the problems of complex structure, inconvenient use, unusable hoisting equipment, etc., and achieve the effect of simple structure, convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

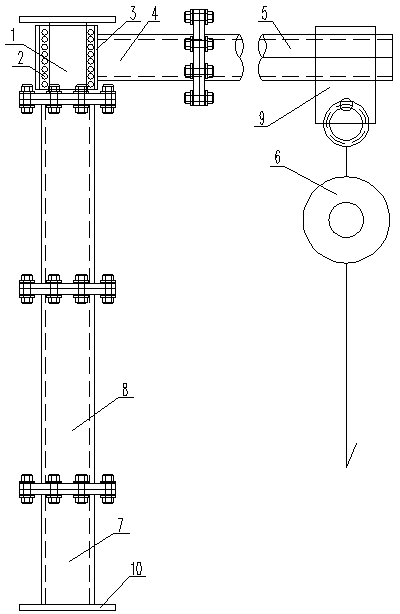

[0014] A hoisting device for vertical transportation, comprising a vertical rod, the upper end of the vertical rod is provided with a bearing column 1, a bearing 2 is sleeved on the bearing column 1, a bearing sleeve 3 is sleeved on the outer surface of the bearing 2, and the bearing sleeve 3 is sleeved on the bearing column 1. A crossbeam 4 perpendicular to the sidewall of the bearing sleeve 3 is fixed on the sidewall of the sleeve 3 , a cantilever 5 is provided at the front end of the crossbeam 4 , and an electric hoist 6 is provided at the front end of the cantilever 5 .

[0015] As a further improvement of the above technical solution, the vertical pole includes a base pole 7 and several support poles 8, the upper end of the base pole 7 and the two ends of the support pole 8 are respectively provided with connecting flanges, and the adjacent support pole 8 and the base pole Both the rod 7 and the support rod 8 are connected through connecting flanges.

[0016] As a further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com