Tramcar lifting device

A technology for lifting equipment and trams, applied in the field of hoisting, can solve problems such as increasing the area of the vehicle base, and achieve the effect of reducing the floor space and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

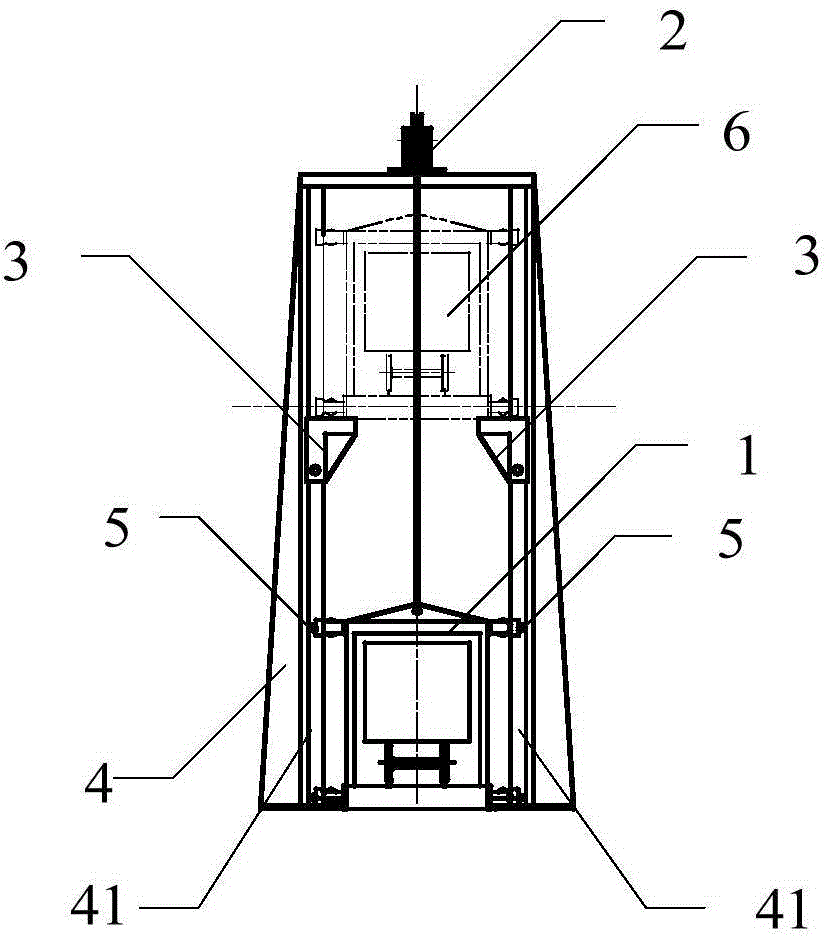

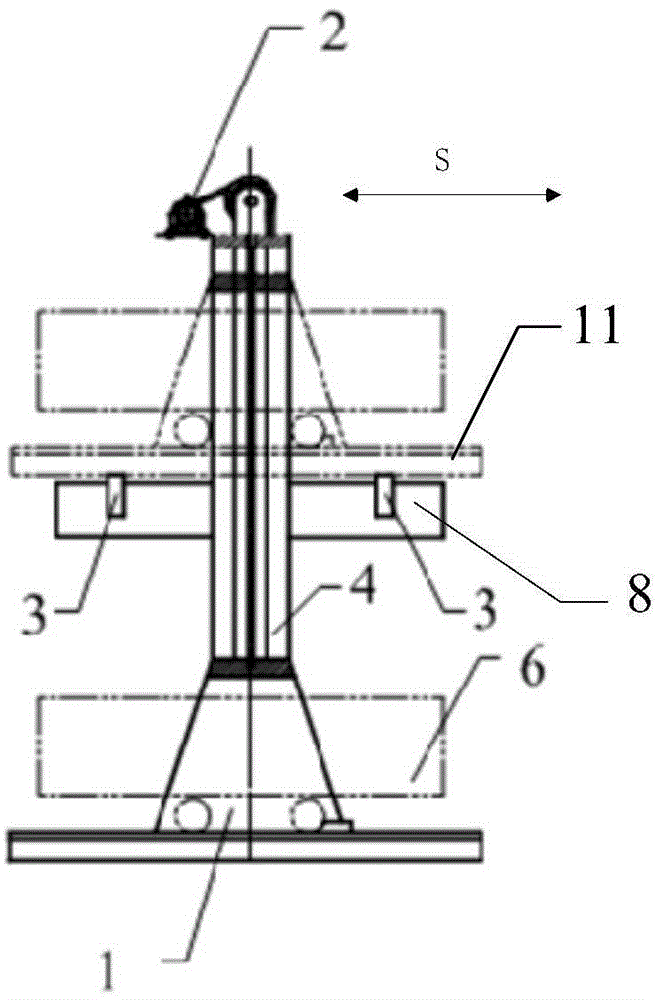

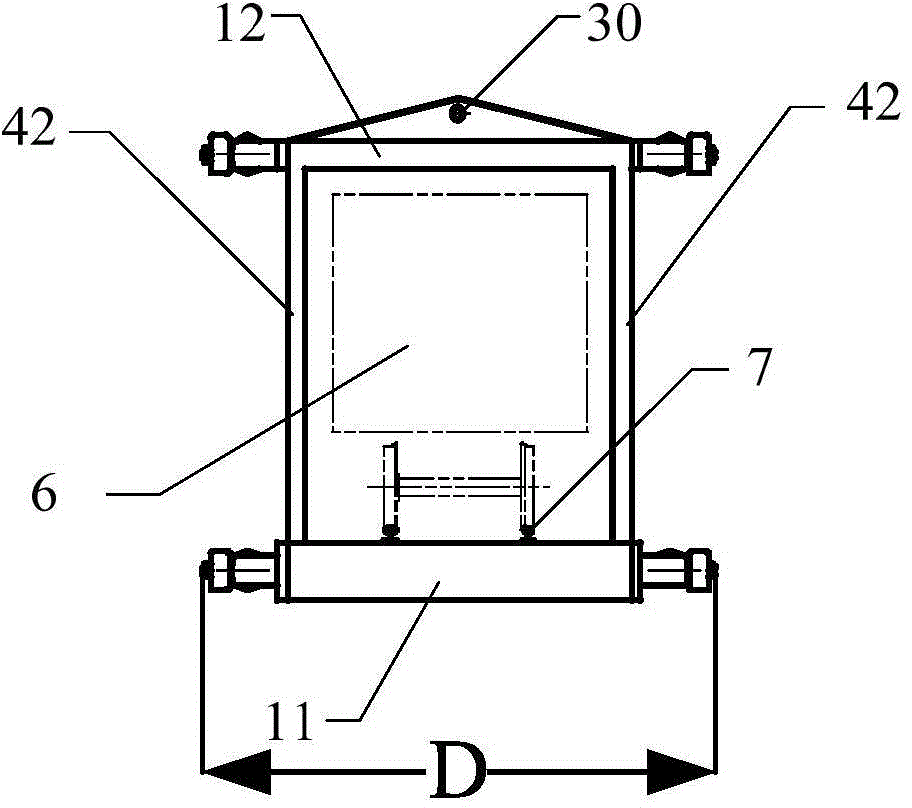

[0022] The tram lifting equipment provided in this embodiment includes at least one lifting unit, figure 1 A side view of a hoisting unit of the tram hoisting device provided in Embodiment 1 of the present invention, figure 2 It is a front view of a lifting unit of a tram lifting device provided by another embodiment of the present invention, image 3 A structural schematic diagram of the lifting platform 1 provided for another embodiment of the present invention, as figure 1 with figure 2 As shown, the lifting unit includes: a lifting platform 1 , a lifting power device 2 , a supporting device 3 , a basic supporting mechanism 4 and a plurality of guide wheel sets 5 . Wherein, the foundation support mechanism 4 adopts a steel frame, including two first side walls 41 perpendicular to the ground. Specifically, the two first side walls 41 may be respectively symmetrically arranged on both sides of the tram 6 .

[0023] Such as figure 1 with image 3 As shown, the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com