Method for aligning high-intensity bolt hole sites of connecting plate of steel beam installation via positioning pins

A technology of high-strength bolts and positioning pins, which is applied in the processing of building materials, construction, building construction, etc., which can solve the problems of labor-intensive and installation of mechanical shifts, long time for alignment, and increased investment in construction costs, etc. problems, achieve good economic benefits, easy operation, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

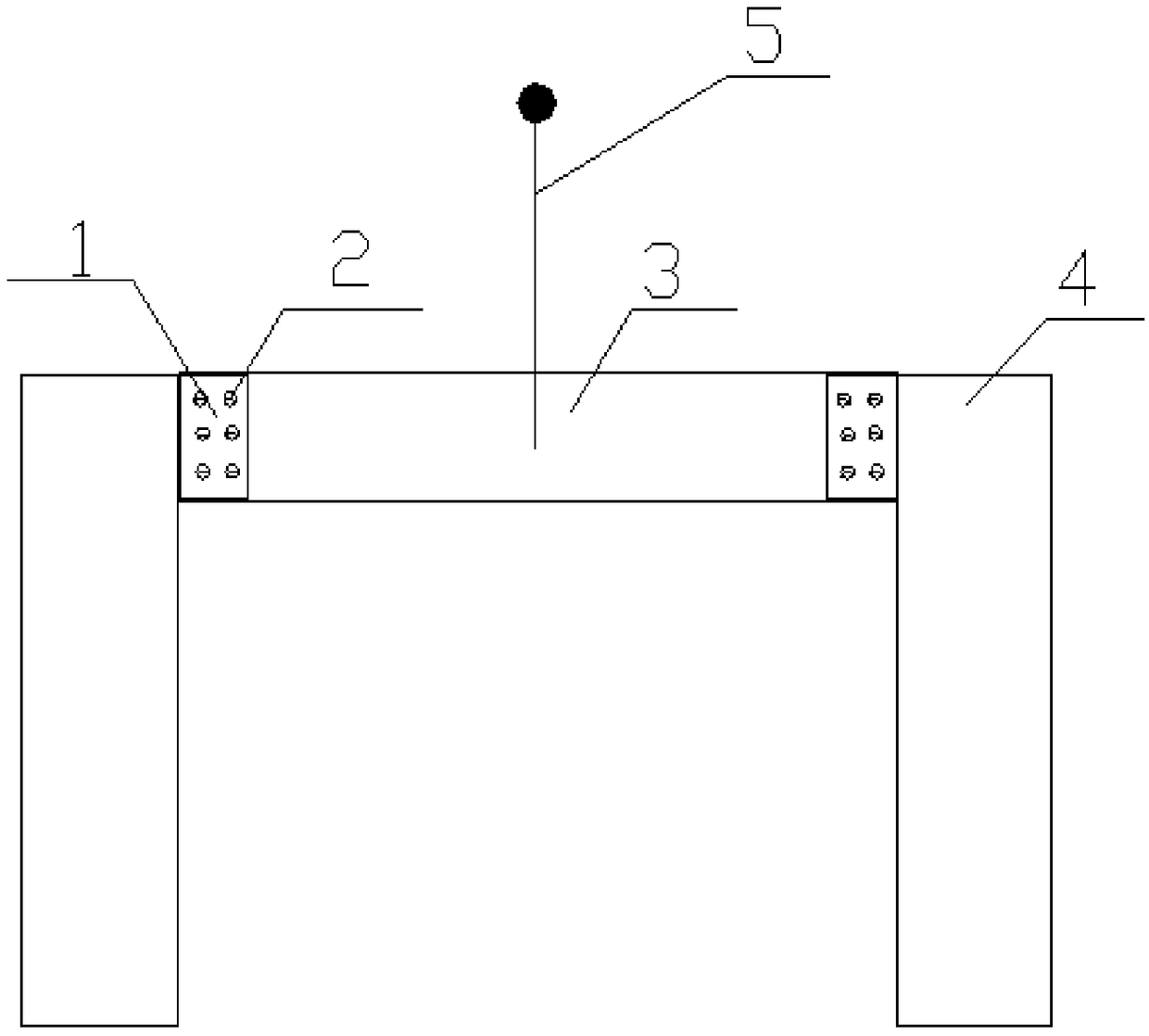

[0018] Figure 1-Figure 7 It is a specific embodiment of the present invention. The specific implementation is as follows:

[0019] In the first step, during the installation of the roof steel beam 3 through the crane sling 5, the high-strength bolt hole 2 that is misaligned between the steel beam 3 and the steel column 4 connecting plate 1 needs to be corrected;

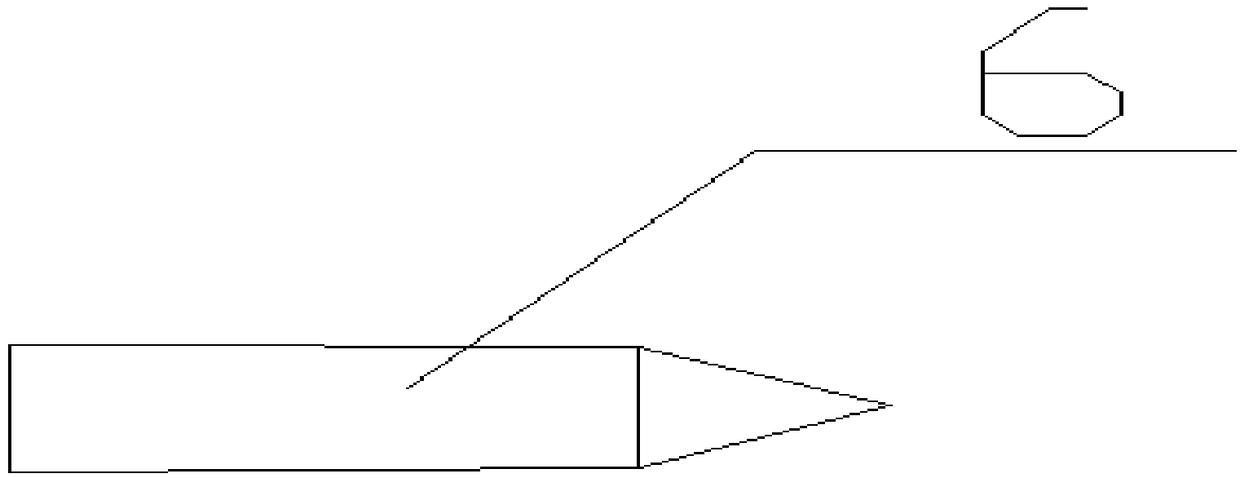

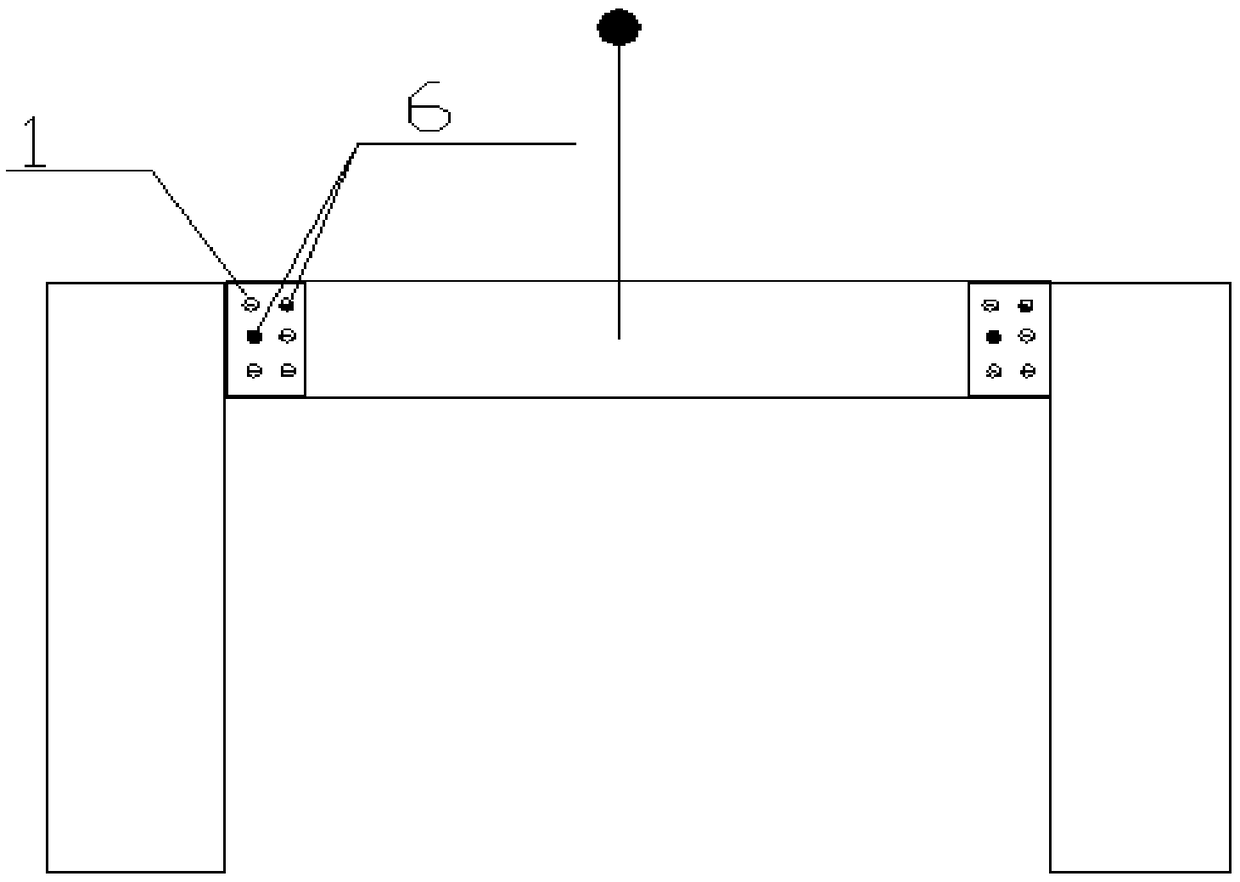

[0020] In the second step, use the processed steel positioning pin 6 to arbitrarily select two high-strength bolt holes 2 with staggered holes in the steel beam 3 and the installation connecting plate 1, and pass through two positioning pins 6;

[0021] The third step is to use external force to hit the positioning pin 6, so that the positioning pin 6 is pushed into the steel beam 3 and the connecting plate 1 to completely align with the high-strength bolt hole 7. The alignment of the two bolt holes determines the bolt holes on all connecting plates. all aligned;

[0022] In the fourth step, high-strength bolts 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com