Programmable upper computer automatic follow-up method

An automatic, position-machine technology, applied in the fields of slitting machinery, earth-moving drilling, mine roof support, etc., can solve the problems of limited processing and storage capacity of the support controller, large differences in geological conditions, and program solidification, etc. The effect of computer interaction experience and work efficiency, reducing the number of downholes, and improving control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

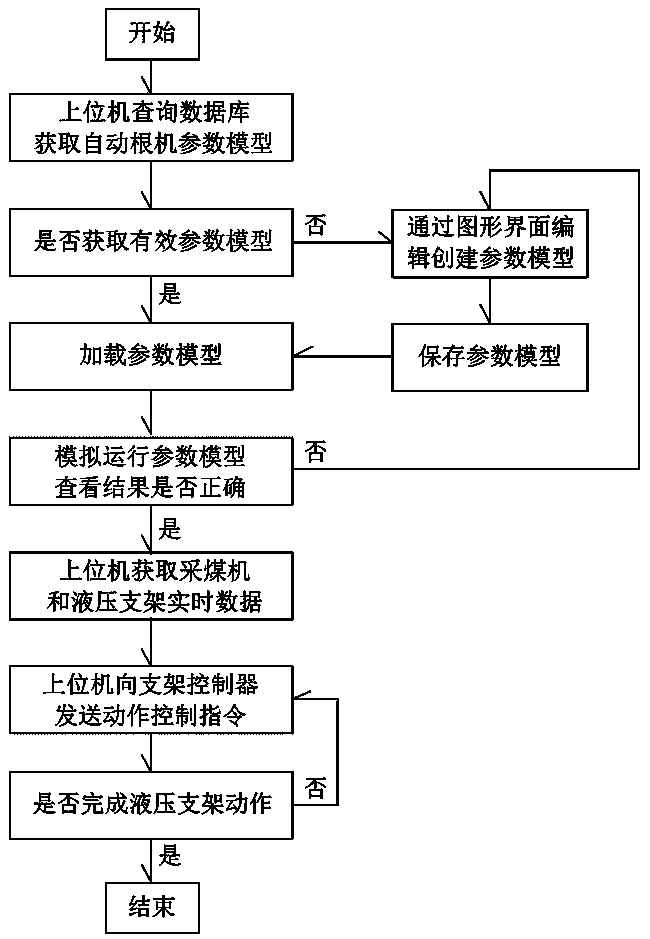

[0020] Such as figure 1 As shown, the programmable upper computer automatic follow-up method of the present invention is carried out according to the following steps:

[0021] The first step, the upper computer queries the database to obtain an effective automatic follow-up parameter model;

[0022] In the second step, the upper computer judges whether the obtained automatic follow-up parameter model is valid, and if it is an effective automatic follow-up parameter model, proceed to the third step; if it is an invalid automatic follow-up parameter model, create an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com