Involute surface multi-cavity oscillating pump

A technology of swing pump and involute surface, which is applied in the field of multi-cavity swing pump with involute surface, can solve the problem of restricting the application fields of single-acting vane pump and double-acting vane pump, aggravating the friction and wear of blade and blade chute, affecting the blade, The service life of the chute and other issues have been achieved to achieve the effects of low vibration and noise, reduced speed requirements, and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

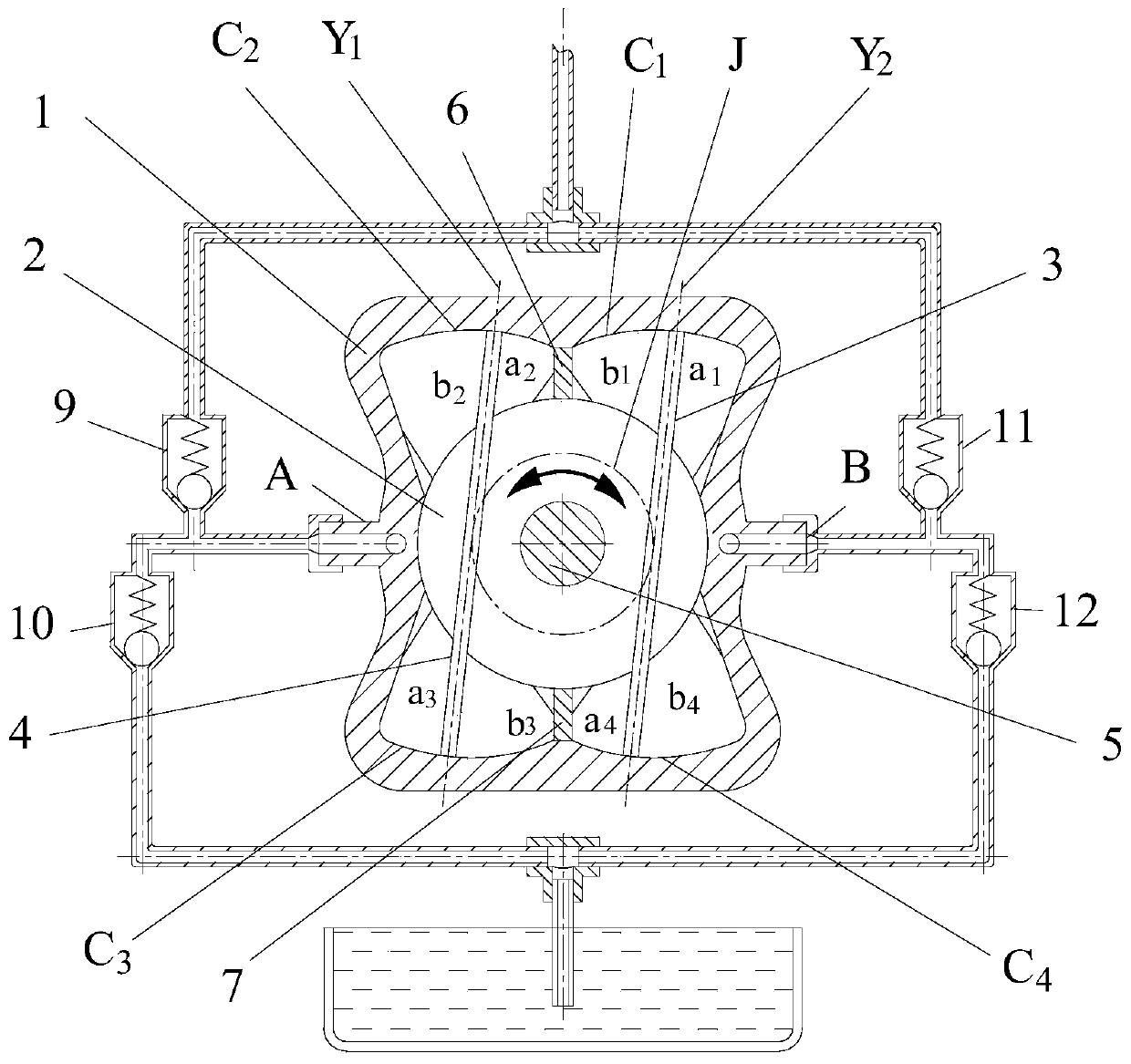

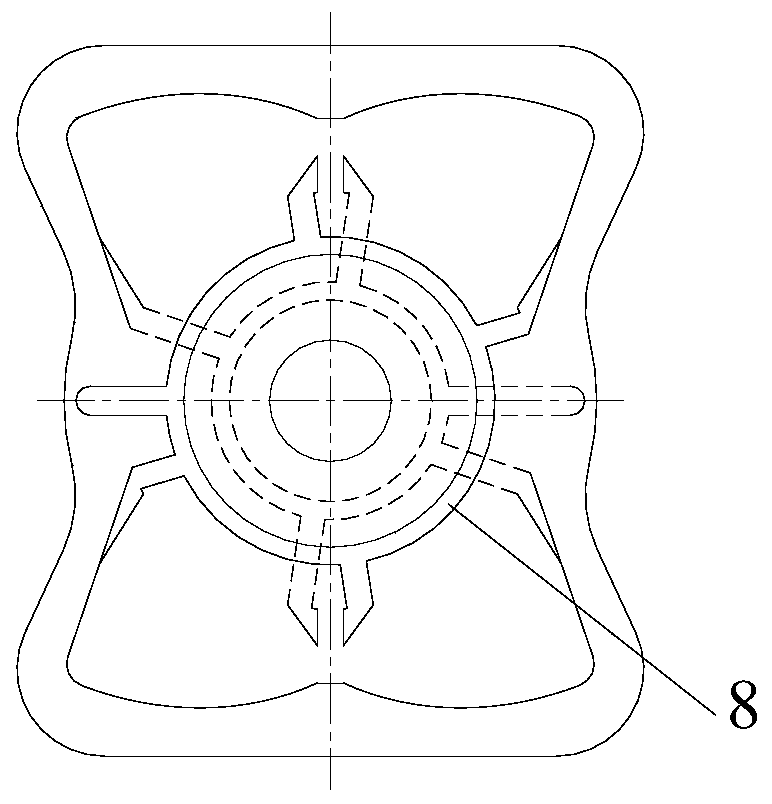

[0020] Figure 1 to Figure 2 It is an embodiment disclosed by the present invention. The involute surface multi-chamber swing pump of the present invention consists of a pump body 1, a rotor 2, a right vane 3, a left vane 4, a transmission shaft 5, an upper partition 6, a lower partition 7, a flow plate 8, oil ports A and B, Check valve 9 to 12 etc. form. There are four involute surfaces on the inner wall of the pump body 1: C 1 、C 2 、C 3 、C 4 , their corresponding base cylinders are all J, and the four involute surfaces C 1 、C 2 、C 3 、C 4 The positions are symmetrical and the dimensions are the same. The rotor 2 is provided with two chutes parallel to each other and symmetrical with respect to the center of the rotor. The distance between the centerlines of the two chutes is equal to the diameter of the base cylinder J. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com