Low rotating speed self-priming extraction equipment

An extraction equipment and self-priming technology, applied in the field of liquid-liquid two-phase solvent extraction equipment, can solve the problems of maintaining the biological activity of biological macromolecules, reducing the stirring shear force, and difficulty in phase separation, avoiding emulsification, Low shear force and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

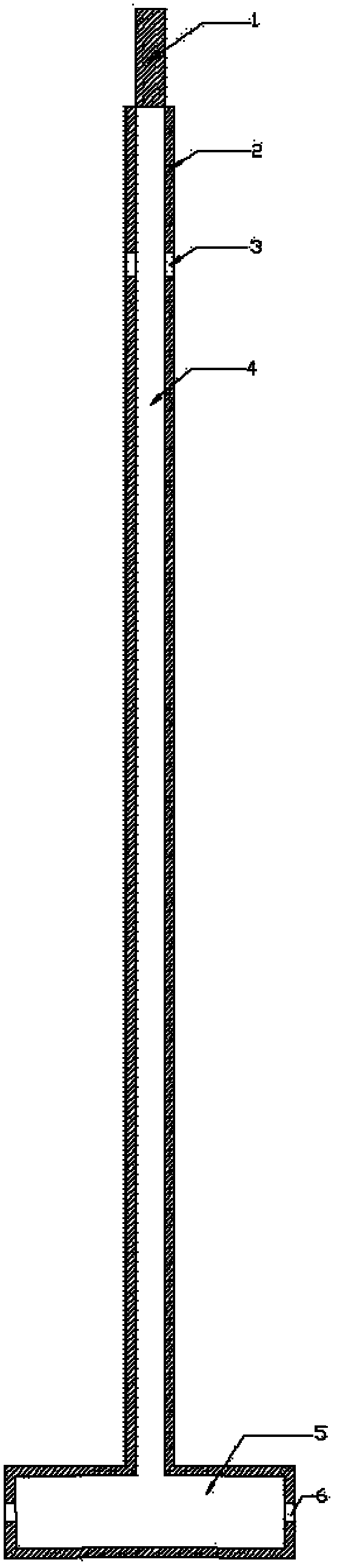

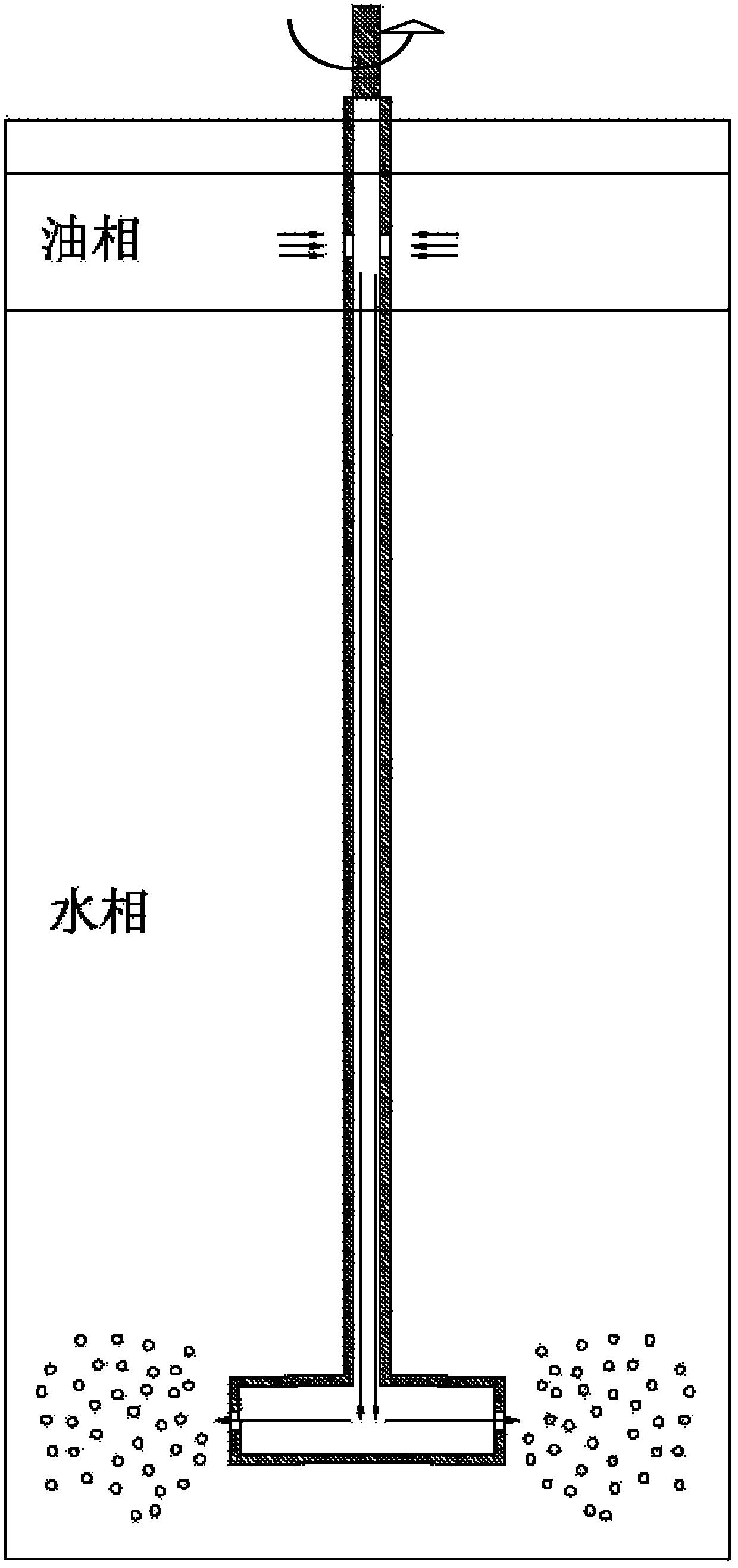

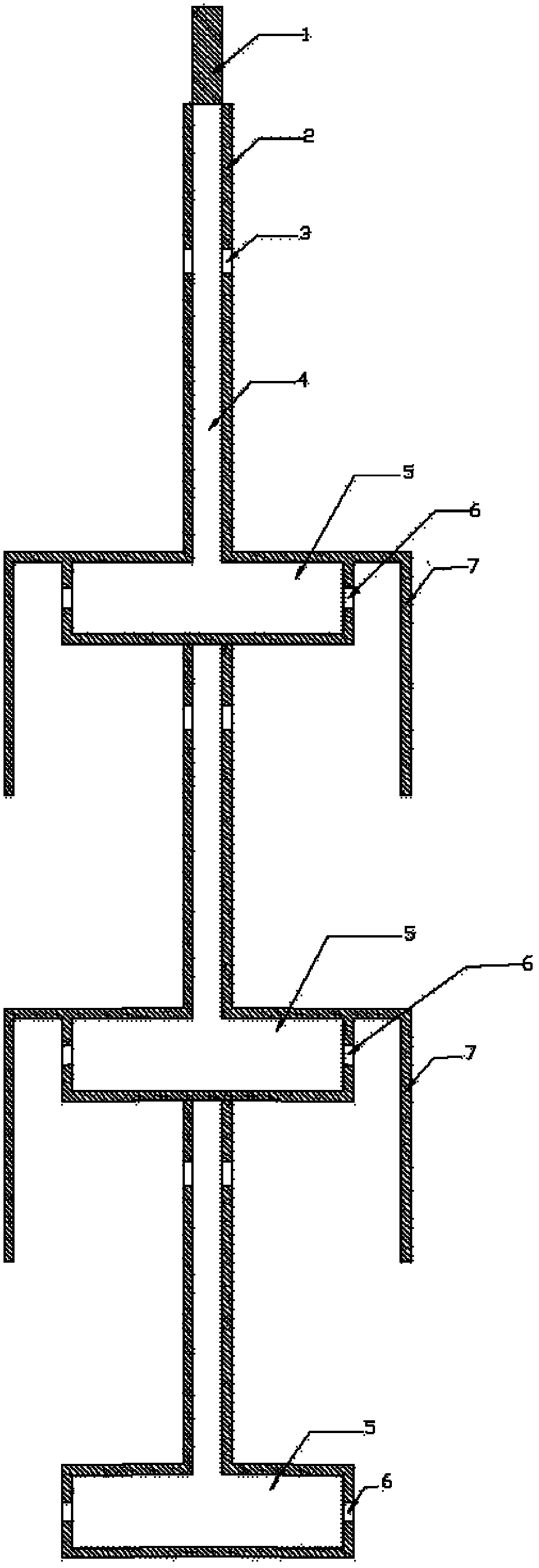

Embodiment 1

[0033] The organic phase is kerosene, and a color developer is added to the kerosene, the water phase is deionized water, and the ratio of the organic phase to the water phase is 1:10. The light phase feed inlet diameter of this low-speed self-priming extraction device is 5 mm, and is located at the relative position of the cavity shaft, with the oil phase as the dispersed phase, the shaft cavity diameter is 6 mm, the drum cavity diameter is 30 mm, and There are 12 relatively small holes with a diameter of 4mm. To achieve the same dispersion effect, the required speed of single-stage self-priming extraction equipment is 500rpm, and the required speed of low-speed self-priming extraction equipment is 170rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com