Disinfection laundry detergent and preparation method

A technology of laundry detergent and defoamer, applied in the field of disinfecting laundry detergent and preparation, can solve the problems of single washing or sterilizing function, low killing rate of bacteria and fungi, strong irritation, etc., and achieves good killing, excellent Wetting, product gentle and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

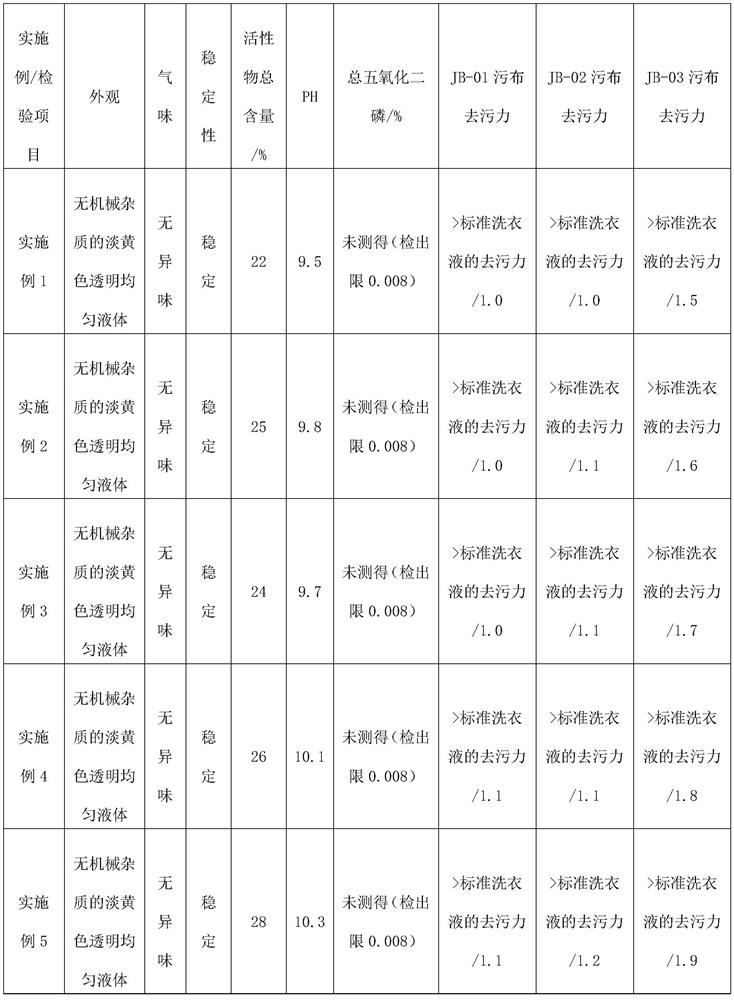

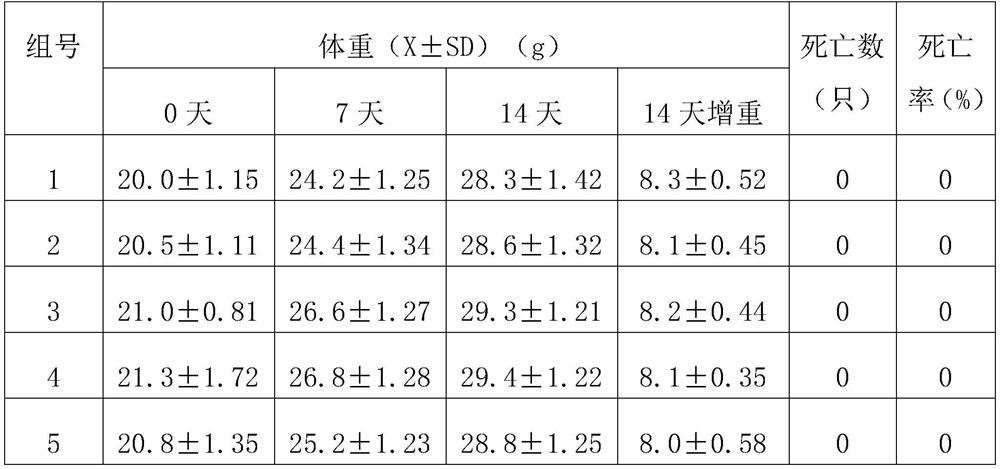

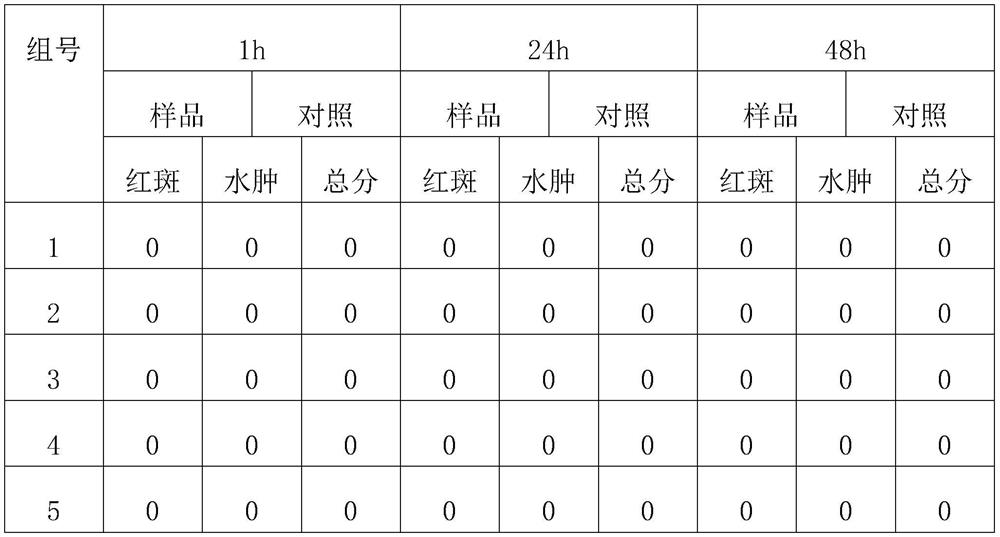

Examples

Embodiment 1

[0029] To prepare a sanitizing laundry detergent:

[0030] 1.1 Raw materials:

[0031] The preparation of disinfectant laundry liquid comprises following raw materials in parts by weight:

[0032] 1 part of sodium ethoxylated sulfate; 1 part of potassium cocoate soap, 5 parts of fatty alcohol-C12-15-polyoxyethylene ether, methyl ethylene oxide and ethylene oxide mono(2-propylheptane ) ether polymer 3 parts, dodecyl dipropylene triamine 1 part, silver ion 0.1 part, tetrasodium glutamic acid diacetate 0.1 part, silicone defoamer 0.05 part, essence 0.1 part, water 75 parts .

[0033] 1.2 Preparation method:

[0034] Contains the following steps:

[0035] (1) Raw materials are prepared according to the proportion; the prepared silicone defoamer is pre-dispersed according to the ratio of silicone defoamer: water=8:1 to obtain a pre-dispersed defoamer;

[0036] (2) First add the remaining water of step (1) into the batching pot;

[0037] (3) Add tetrasodium glutamic acid diace...

Embodiment 2

[0041] To prepare a sanitizing laundry detergent:

[0042] 2.1 Raw materials:

[0043] 6 parts of sodium α-olefin sulfonate; 5 parts of potassium cocoate soap, 30 parts of alkyl glycosides, 25 parts of polymers of methyl oxirane and ethylene oxide mono(2-propylheptane) ether, 5 parts of dodecyl dipropylene triamine, 2 parts of silver ions, 1 part of tetrasodium glutamic acid diacetate, 0.2 parts of silicone defoamer, 0.6 parts of essence, 10 parts of water.

[0044] 2.2 Preparation method:

[0045] Contains the following steps:

[0046] (1) Prepare the raw materials according to the proportion; pre-disperse the prepared silicone defoamer according to the ratio of silicone defoamer: water = 10:1, to obtain a pre-dispersed defoamer;

[0047] (2) First add the remaining water of step (1) into the batching pot;

[0048] (3) Add tetrasodium glutamic acid diacetate prepared in step (1) to the batching pot under stirring until it dissolves completely;

[0049] (4) In the state o...

Embodiment 3

[0052]To prepare a sanitizing laundry detergent:

[0053] 3.1 Raw materials:

[0054] 2 parts of sodium ethoxylated sulfate; 2 parts of potassium cocoate soap, 10 parts of fatty alcohol-C12-15-polyoxyethylene ether, methyl ethylene oxide and ethylene oxide mono(2-propylheptane ) ether polymer 8 parts, dodecyl dipropylene triamine 2.5 parts, silver ions 0.5 parts, tetrasodium glutamic acid diacetate 0.2 parts, silicone defoamer 0.08 parts, essence 0.2 parts, water 55 parts .

[0055] 3.2 Preparation method:

[0056] With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com