A Method of Gas Pipeline Leakage Detection and Location Based on Mathematical Model

A mathematical model and leak detection technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of poor detection effect, cumbersome process and difficult operation of large pipelines, and achieve the level of efficient leak detection and location , Simple operation process, less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

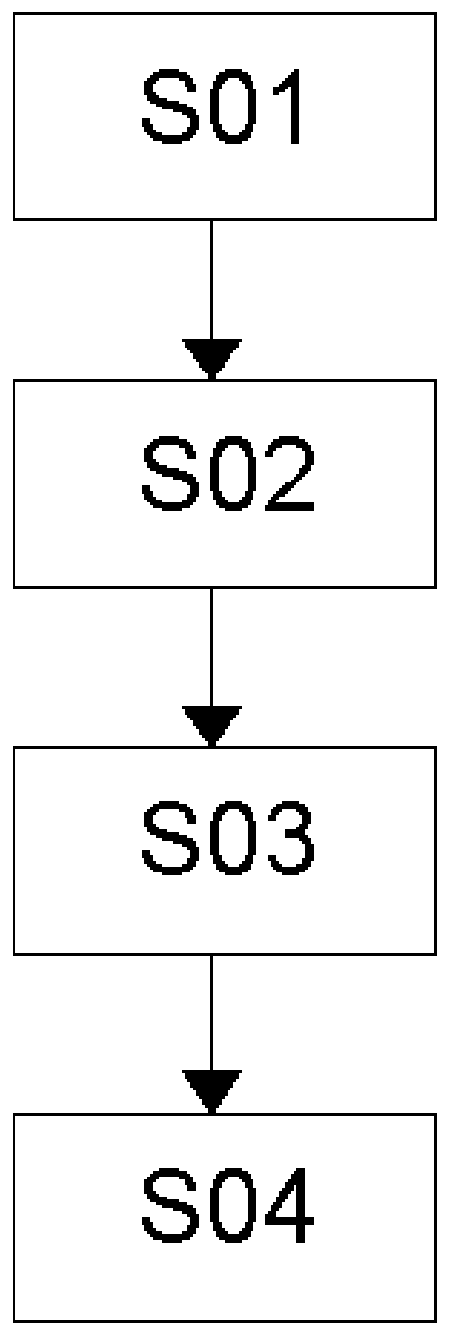

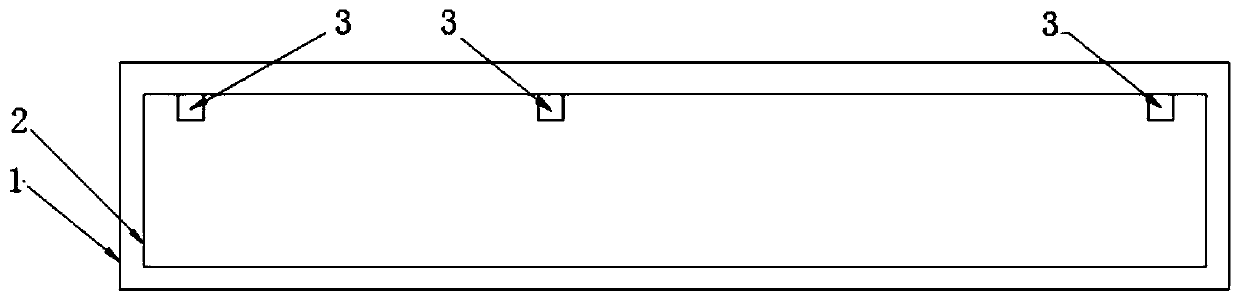

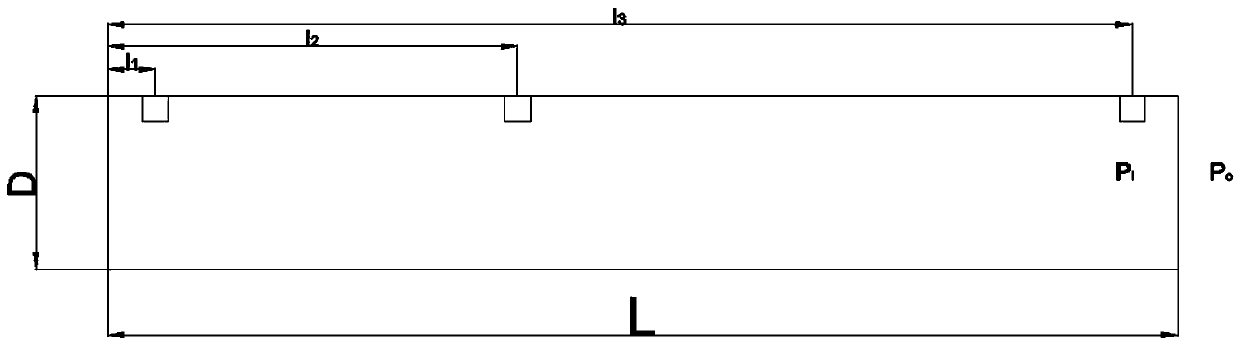

[0022] A method for detecting and locating gas pipeline leaks based on a mathematical model. According to the value of the pipeline pressure at different times and combined with the initial physical parameters, the position of the pipeline leakage point is obtained through the mathematical model; the initial interior of the test pipeline is in a positive pressure state , both ends of the pipeline are closed during the test; the specific steps are as follows:

[0023] Step S01: record the original parameters of the pipeline;

[0024] Step S02: Conduct a test and collect three sets of data on the pressure at both ends and the middle of the pipeline as a function of time;

[0025] Step S03: Use the recorded original parameters of the pipeline as the input of the mathematical model, any set of data obtained from the test as the input variable of the mathematical model in the algorithm, and the location of the pipeline leak as the output of the mathematical model;

[0026] Step S0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com