Ion beam etching equipment and etching method thereof

A technology of ion beam etching and ion beam, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc. It can solve the problems of not having an independent loading and unloading chamber, chip damage, and long time to establish a vacuum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

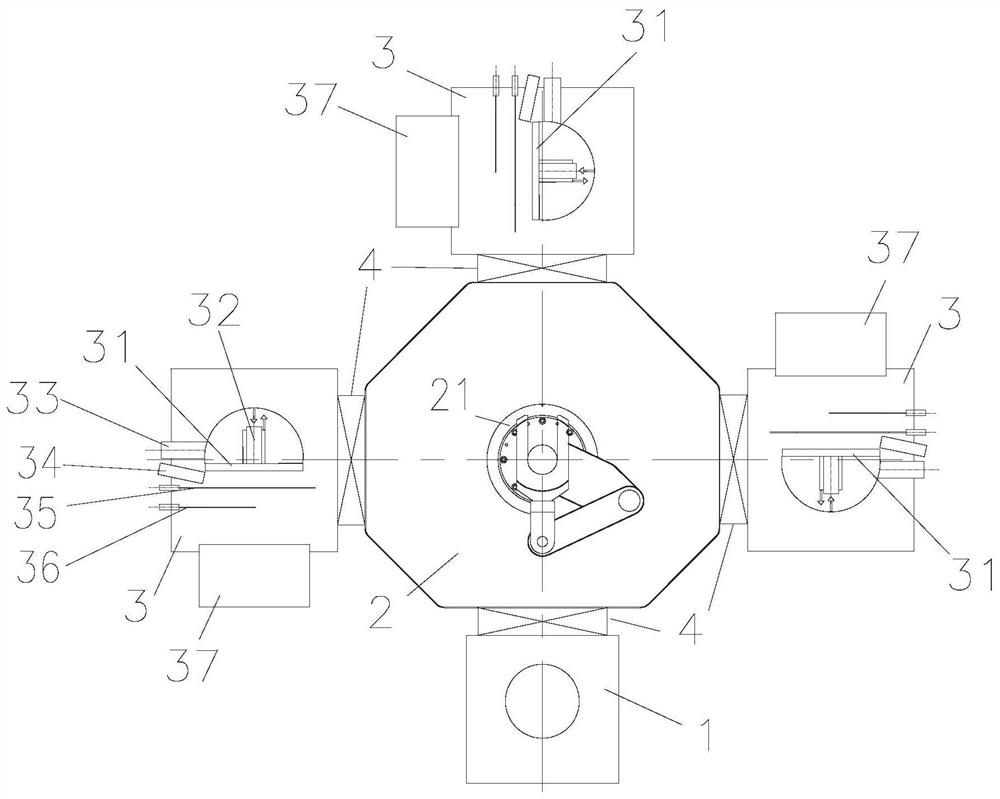

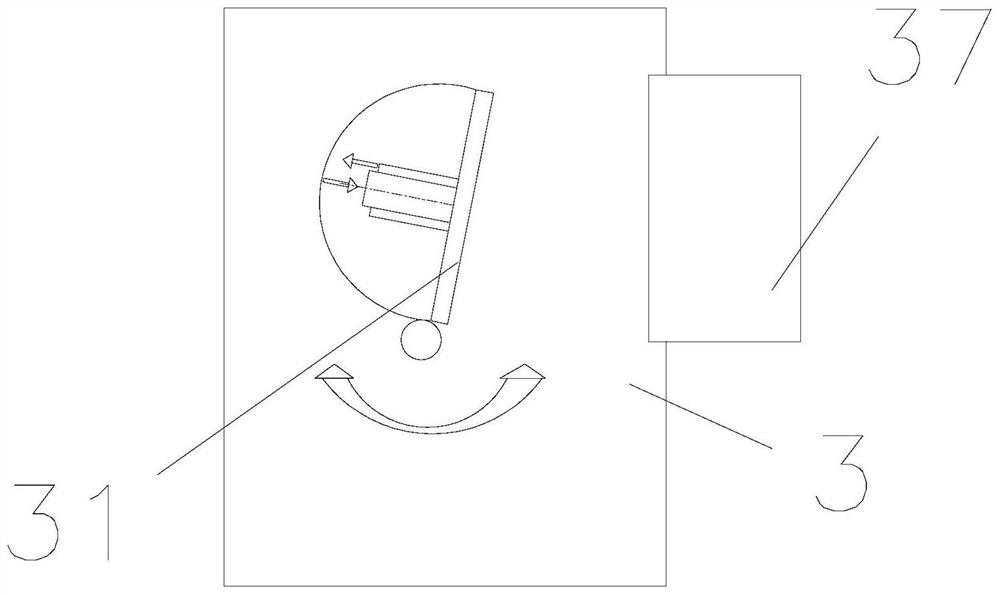

[0036] Such as figure 1 and figure 2 As shown, the ion beam etching equipment of this embodiment includes a loading and unloading chamber 1, a transport chamber 2 for transporting substrates (such as infrared devices) and at least one etching chamber 3 for etching substrates; The loading and unloading chamber 1 and the etching chamber 3 are respectively connected to the transfer chamber 2; an isolation valve 4 is provided between the loading and unloading chamber 1 and the transfer chamber 2; between the transfer chamber 2 and the etching chamber 3 An isolation valve 4 is provided; a transfer mechanism 21 for transferring substrates is provided in the transfer chamber 2 .

[0037]In the present invention, the provided loading and unloading chamber 1 is used to store different types of substrates, and a variety of different types of substrates can be placed in one loading and unloading. 1 and the transfer between the etching chamber 3, at least one etching chamber 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com