High-voltage cable leading-in device of field emission electron gun

A technology of high-voltage cables and lead-in devices, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of insufficient ground withstand voltage, insufficient withstand voltage of high-voltage cables, and easy damage of high-voltage cables of equipment, and achieve stable quality and improve. The effect of imaging quality and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides an introduction device for a high-voltage cable of a field emission electron gun, which is used to provide working power for the field emission electron gun, wherein the field emission electron gun is arranged in an electron gun chamber with an ultra-high vacuum.

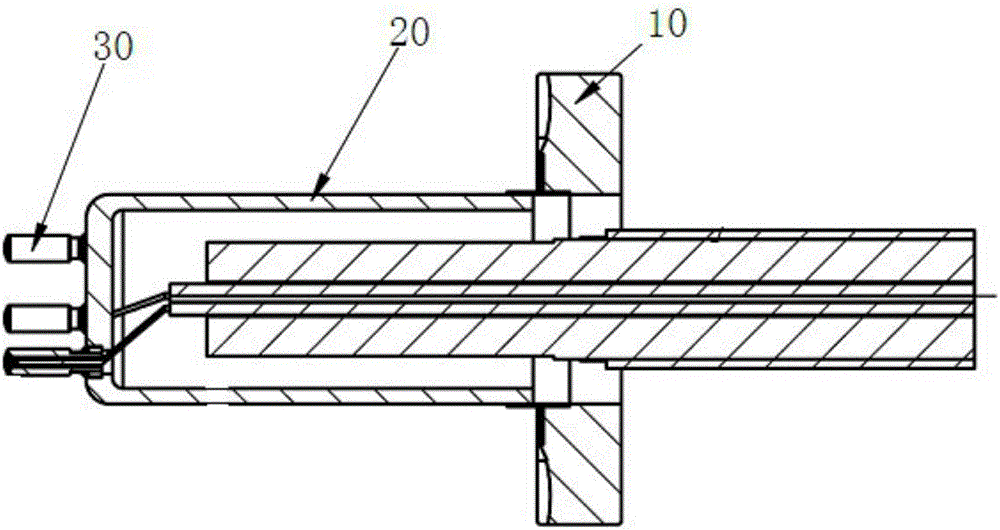

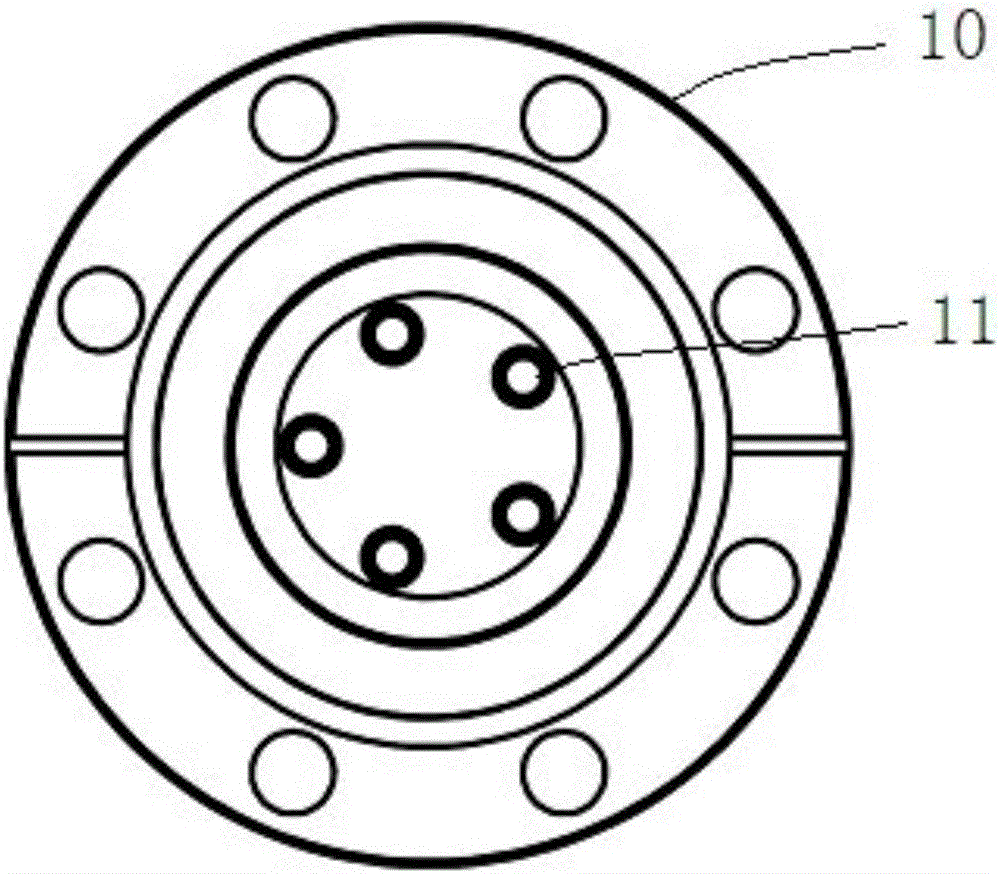

[0030] refer to figure 1 with figure 2 , the lead-in device of the field emission electron gun high-voltage cable of the present embodiment is installed in the flange 10 both sides in the electron gun chamber, and the high-voltage power supply input end is that the multi-strand high-voltage cable is introduced into the electron gun chamber by the outside of the flange 10; The end, that is, the high-voltage sealing electrode 30 is located on the inside of the flange 10, one end of which is coupled to the high-voltage cable, and the other end is coupled to the relevant components of the field emission electron gun, and the relevant components specifically refer to the emitter cathode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com