Method for preparing oxygen carrier particles for restraining release of sulfur-containing gas

A technology of gas release and oxygen carrier, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as unfriendly use environment, complex equipment structure, and complicated process, and achieve safe and reliable processes and equipment , Good sulfur fixation efficiency, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

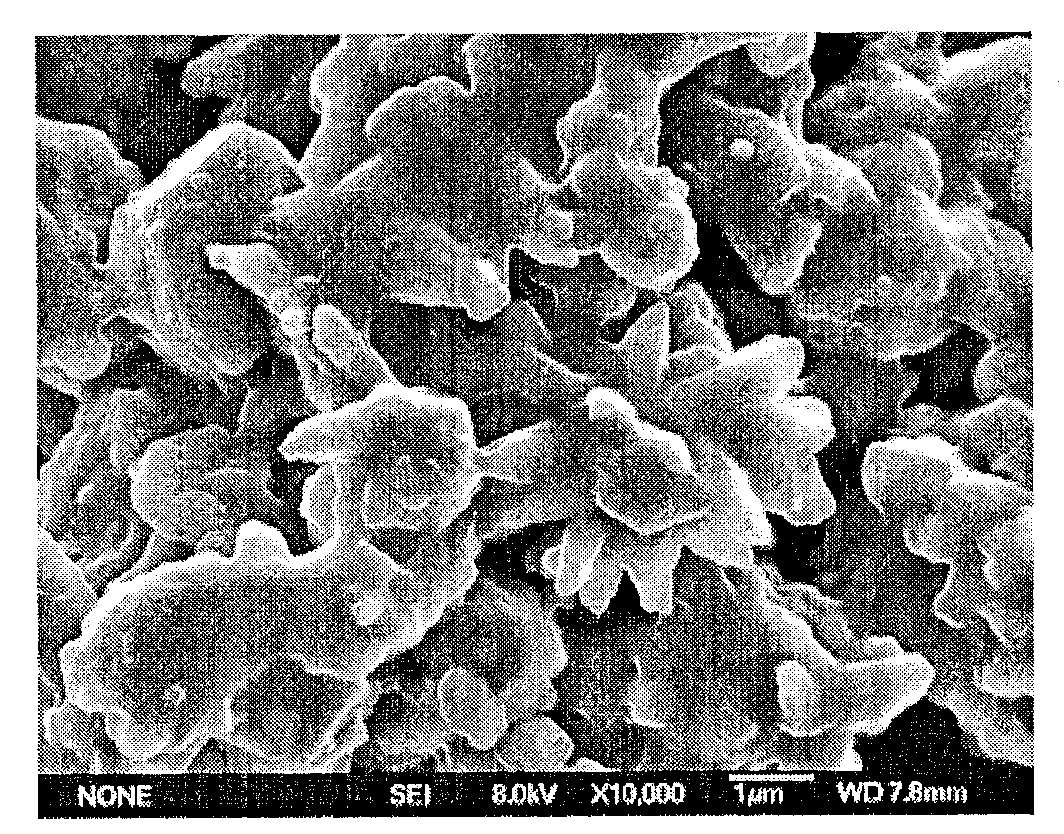

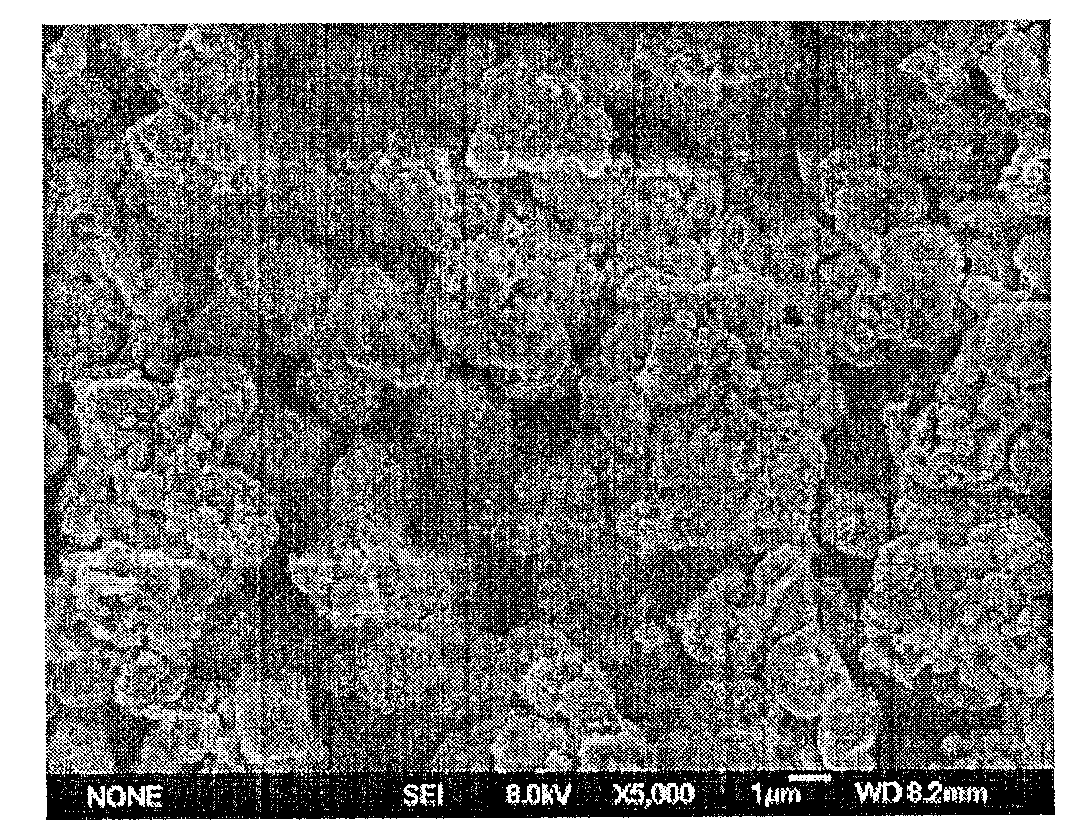

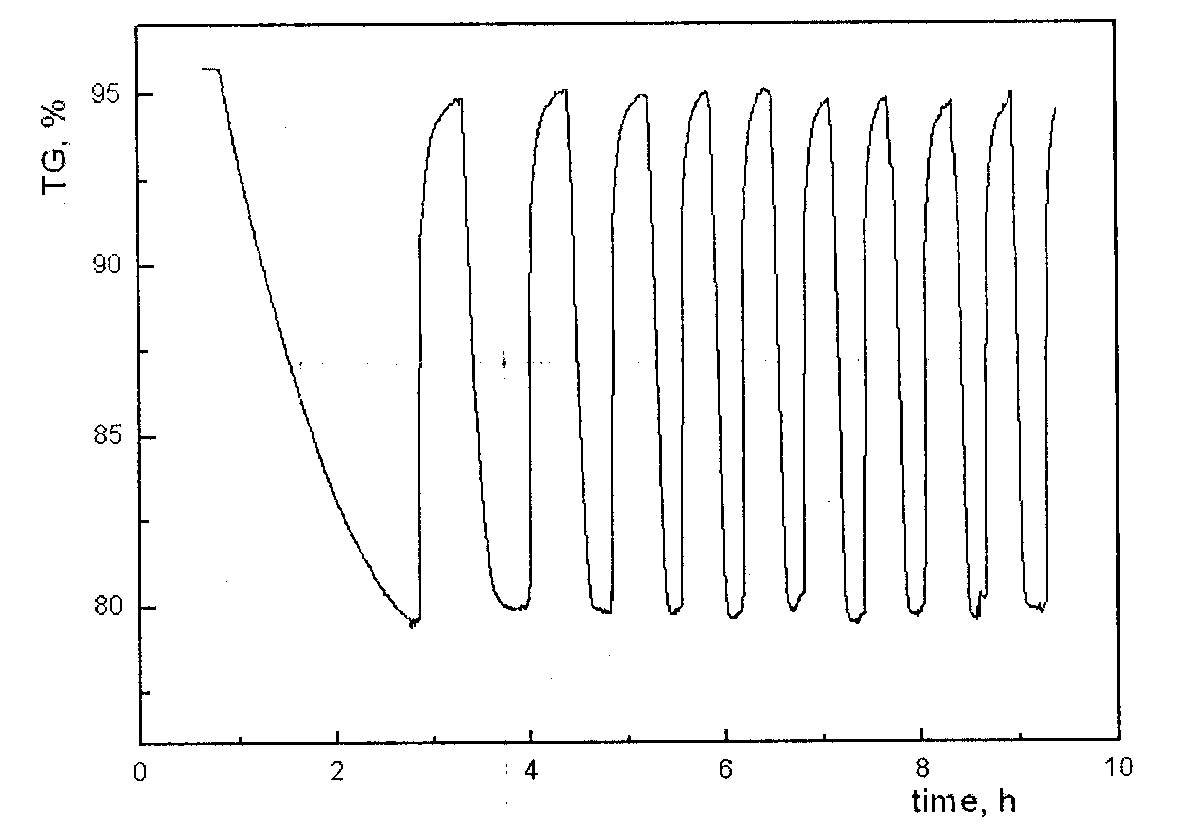

[0019] 5gCaSO 4 With 40g mass percent concentration of 20% CaCl 2 and Na 2 CO 3 The solution was mixed, and 1 g of surfactant lauryl polyoxyethylene ether C was added 12 h 25 O(CH 2 CH 2 O) 9 H, stir well, prepare the paste and let it stand for 6 hours; move the paste into a glass forming device and squeeze it into granules; the granulated granules are placed in the air to dry naturally for 6 hours, and then quickly move them into a constant temperature In the drying oven, after drying at 150°C for 10 hours, take it out, put it in a muffle furnace and calcinate at 300°C for 6 hours to obtain the oxygen carrier particles after adding the sulfur fixing agent. Electron scanning electron microscope (SEM) photo figure 1 Show the oxygen carrier that present embodiment makes, figure 2 Show the particles of the oxygen carrier prepared in this embodiment after multiple cycles of reaction, image 3 The thermal analysis curve of the oxygen carrier prepared in this example in 2...

Embodiment 2

[0021] 2.75gCaSO 4 With 40g mass percent concentration of 20% CaCl 2 and Na 2 CO 3 The solution was mixed, and 1 g of surfactant lauryl polyoxyethylene ether C was added 12 h 25 O(CH 2 CH 2 O) 9 H, stir well, prepare the paste and let it stand for 6 hours; transfer the paste into a glass syringe and squeeze it into granules; the granulated granules are placed in the air to dry naturally for 6 hours, and then quickly move them into constant temperature drying In the box, take it out after drying at a constant temperature of 150°C for 10 hours, and place it in a muffle furnace for calcination at 600°C for 12 hours to obtain the oxygen carrier particles after adding the sulfur-fixing agent; scanning electron microscope (SEM) photos Figure 4 The photos of the oxygen carrier particles prepared in this example are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com