Reliability detecting device for slot type photoelectric sensor

A technology of photoelectric sensors and detection equipment, applied in the direction of instruments, etc., can solve the problems of safety and reliability, guarantee equipment, etc., and achieve the effect of safe and reliable equipment and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

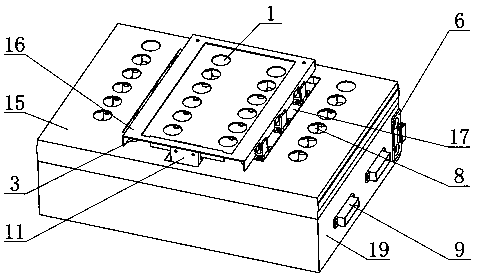

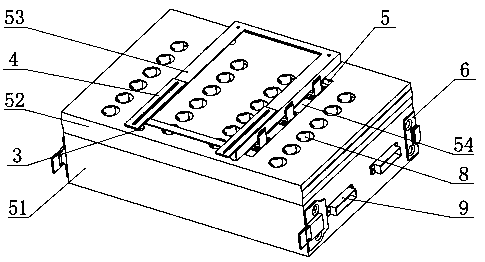

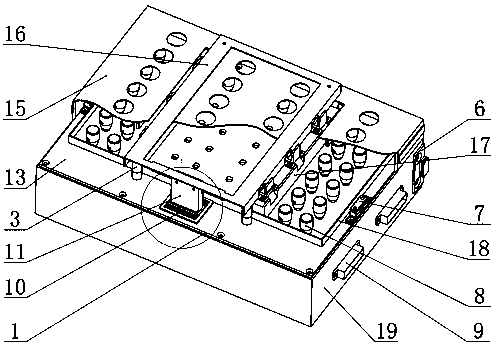

[0021] Such as figure 1 , figure 2 As shown, the present invention provides a kind of reliability detection equipment of slot-type photoelectric sensor, including main test box 1 and expandable sub-test box 5 adopting sealing arrangement, in main test box 1, described main test box casing 19 The outer side is provided with snap close 6, and described main test box casing 19 is provided with main test box cover 15, and described main test box cover 15 is provided with some observation holes, and described main test box cover 15 is provided with There is a main test box light cutting plate 16, which is loosely connected with the connecting rod 11 and placed on the light cutting plate limit post 3; in the sub test box 5, the outside of the sub test box body 51 is provided with Buckle 6, described sub-test box casing 51 is provided with sub-test box cover 52, and described sub-test box cover 52 is provided with some observation holes, and described sub-test box cover 52 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com