Metal piece processing equipment capable of continuously melting metal block and manufacturing method

A technology of process equipment and manufacturing method, which is applied in the field of metal parts process equipment and manufacturing, can solve the problems of increasing the cost of the process, and achieve the effect of continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to make the above objects, features and features of the present invention more comprehensible, the relevant embodiments of the present invention are described in detail as follows with reference to the accompanying drawings.

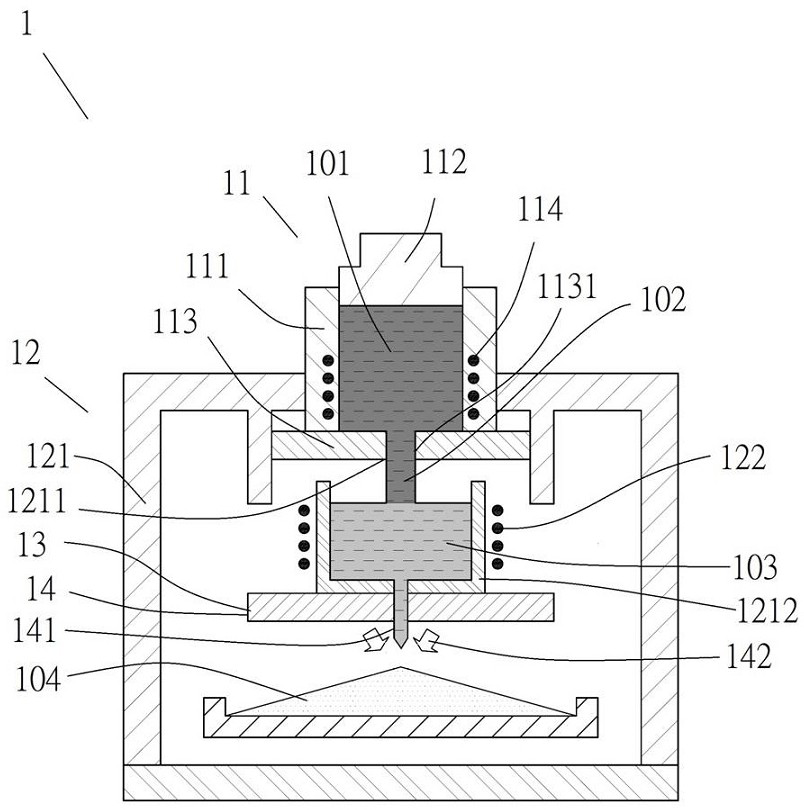

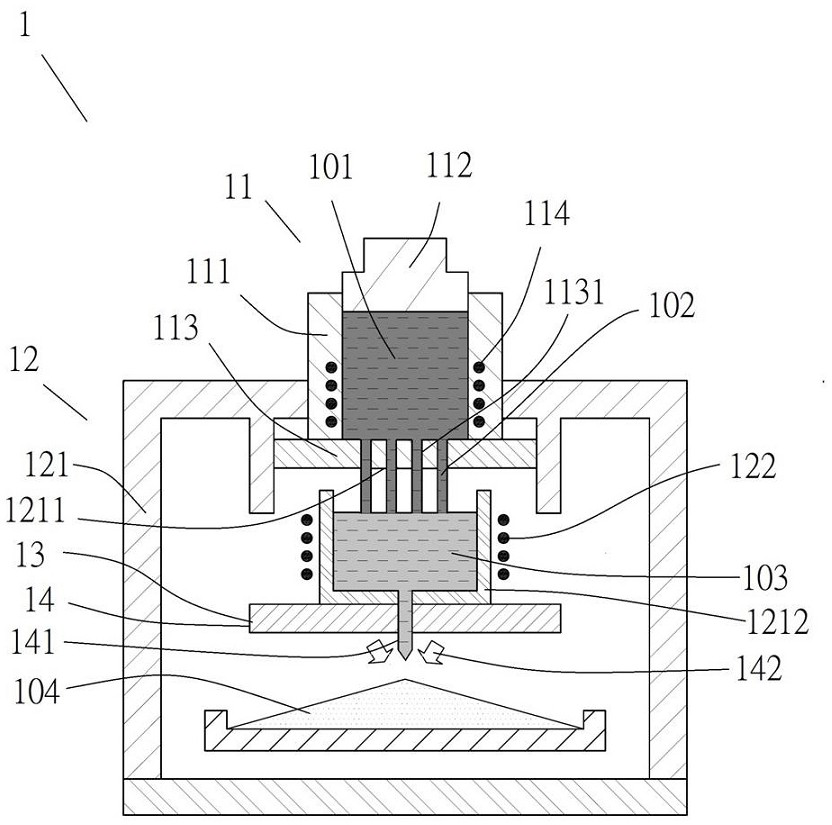

[0085] figure 2 It is a schematic cross-sectional view of the metal part manufacturing equipment according to the first embodiment of the present invention. The metal piece manufacturing equipment 1 can be a kind of equipment that utilizes a vacuum induction melting gas atomization (VIGA) process combined with an extrusion process. The metal piece manufacturing equipment 1 includes: an extrusion device 11 , a melting device 12 and a forming device 13 . The extrusion device 11 includes: an accommodating portion 111 , an extrusion rod 112 and an extrusion mold 113 . The accommodating portion 111 is used for accommodating a metal block 101 . In one embodiment, the accommodating portion 111 is a ladle. The extruding rod 112 is used for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com