Robust fuzzy predictive fault-tolerant control method for interval time-varying-delaying system

A time-varying time-delay and fuzzy prediction technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as poor ability to suppress fault derivatives, not suitable for industrial applications, and cannot be processed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] The present invention conducts experimental research on the outlet temperature of the nonlinear continuous stirred tank (CSTR) process, and the results are as follows.

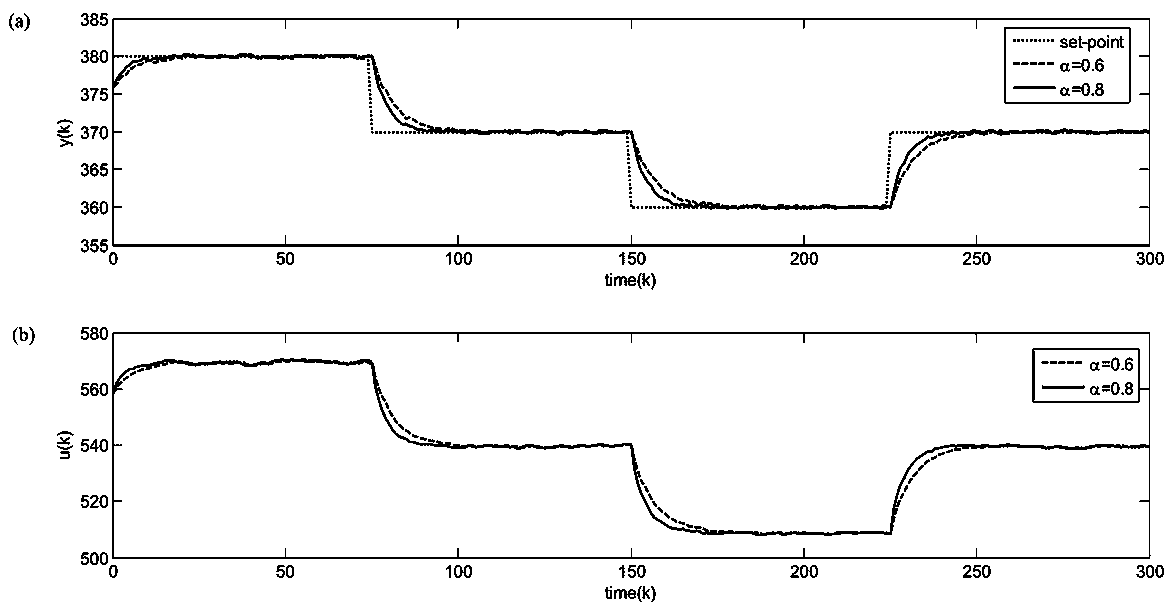

[0146] Such as figure 2 As shown, consider two groups of different constant faults to evaluate the control performance of the system, respectively α = 0.6, α = 0.8. figure 2 (a) is the output response curve of the system. It is obvious from the figure that the control performance of the proposed method deteriorates as the fault α becomes severe. However, the derivation of faults can be effectively suppressed by the proposed method, and the output response can be guaranteed to be smooth and fast to track the set value. figure 2 (b) is the graph of the system control input. It can be seen from the figure that with the seriousness of fault α, the effect of control input becomes worse. However, it can be found that the proposed method will give a fast control input to track the change of setpoint and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com