Vehicle logistics scheduling method and device, storage medium, terminal

A scheduling method and logistics technology, applied in logistics, biological models, instruments, etc., can solve problems such as low utilization rate of transportation resources, failure to meet the expectations of automobile manufacturers and customers, and slow order response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

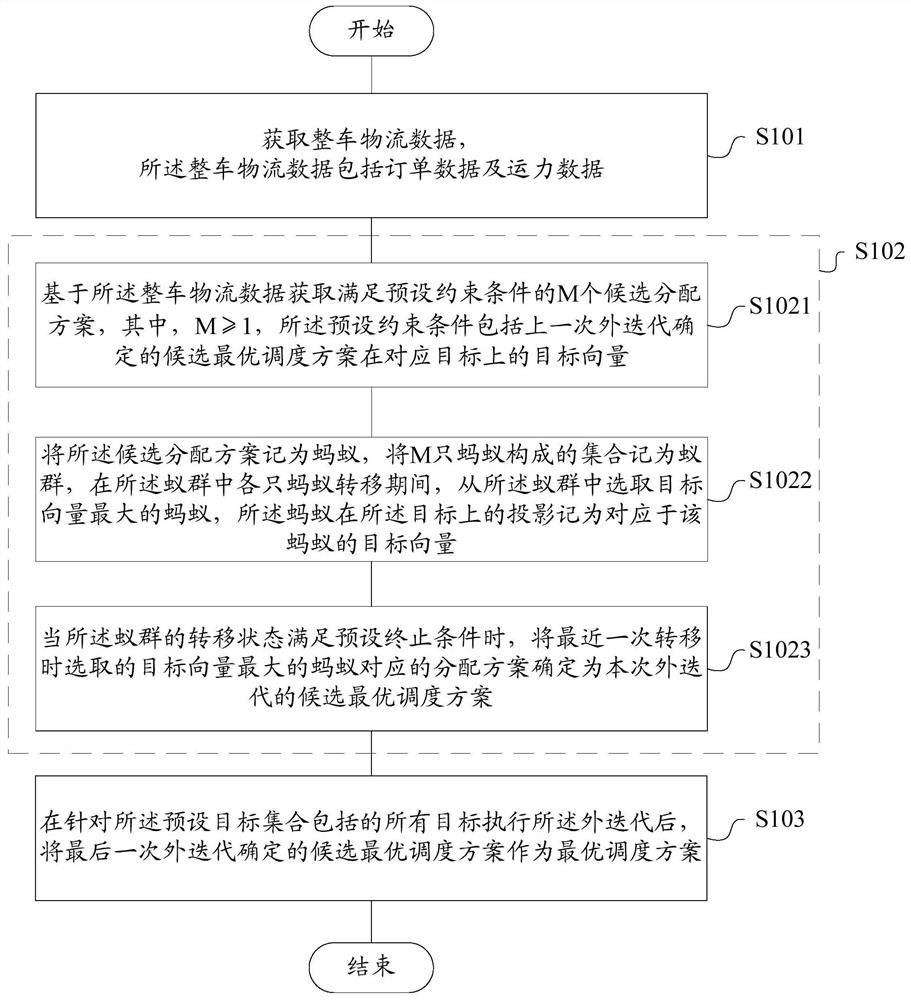

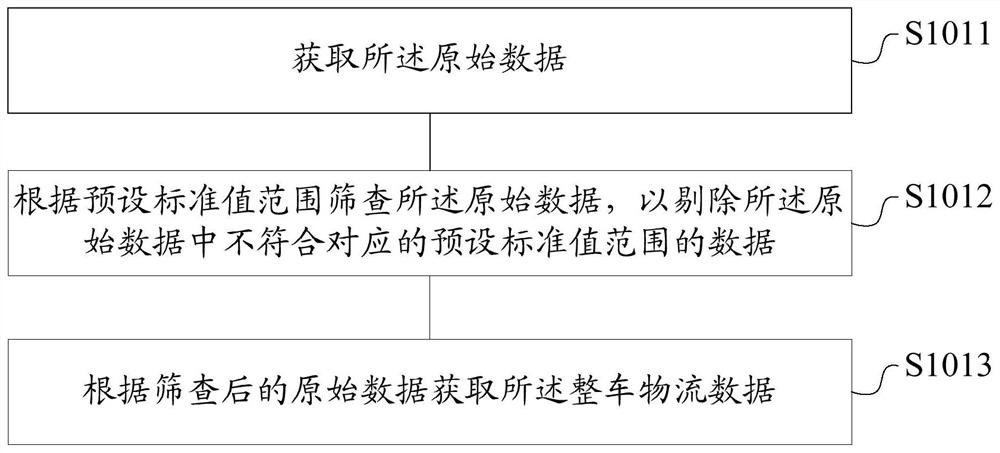

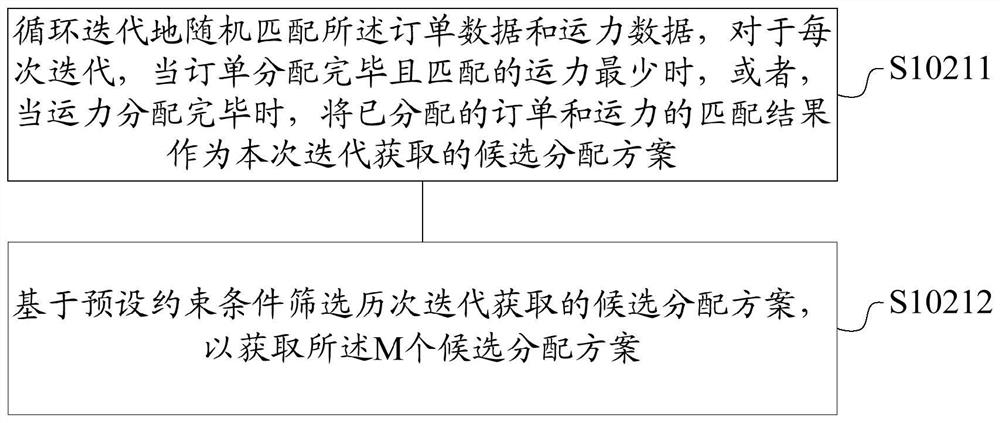

Method used

Image

Examples

Embodiment Construction

[0042] Those skilled in the art understand that, as mentioned in the background technology, the traditional vehicle logistics scheduling mode does not optimize the loading of task objectives, nor does it fully consider the constraint requirements of the input orders themselves, but simply assigns orders to vehicles manually The way to form a scheduling plan (that is, scheduling scheme). It is precisely because of the deficiencies in manual scheduling in the existing vehicle logistics scheduling scheme that there are many shortcomings such as few variables to consider, non-optimal scheduling scheme, low utilization rate of transportation resources, and full order response speed, which cannot be used in practical applications. Satisfying the constraints proposed from the perspective of business contracts and other aspects will cause damage to stakeholders in all aspects of the task, and will result in invalid solutions due to ignorance of some realistic factors in the scheduling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com