Power plant operation training system based on VR virtual technology

A training system and virtual technology technology, which is applied in the field of power plant operation training system based on VR virtual technology, can solve problems such as losses, technical personnel, power plant enterprise risks, and potential risks of equipment, and achieve strong scalability, save training costs, and avoid risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

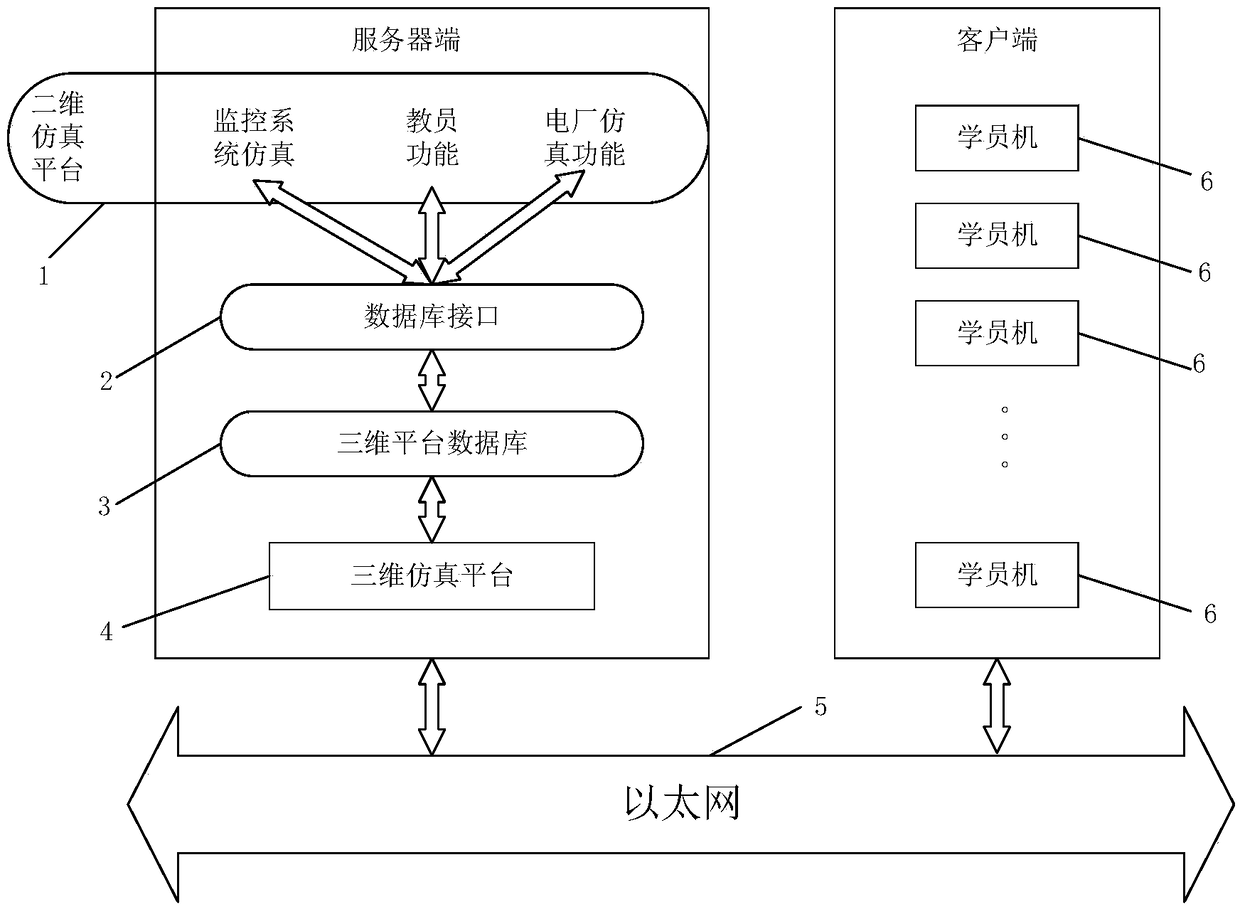

[0030] Such as figure 1 As shown, a power plant operation training system based on VR virtual technology, the system includes a server for power plant operation training and a client for the actual operation of trainees, and the server and client are connected through Ethernet 5;

[0031] The server side includes:

[0032] Two-dimensional simulation platform 1: monitor and simulate power plant equipment, specifically, two-dimensional simulation platform 1 realizes power plant simulation, monitoring system simulation and teacher functions, issues instructions to the three-dimensional platform through the two-dimensional simulation platform 1, and receives feedback from the three-dimensional platform ;

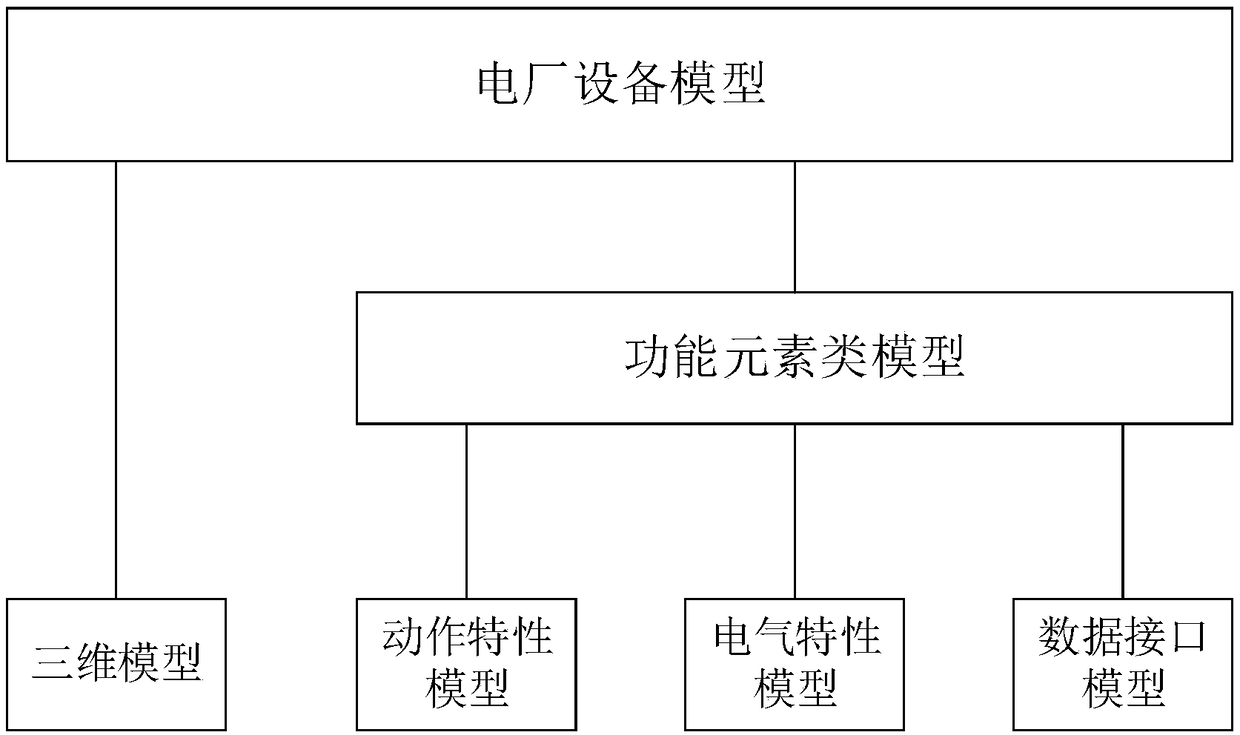

[0033] 3D simulation platform 4: establish a power plant equipment model and form a virtual scene of the power plant, and at the same time receive the actual operation data of the trainees on the client side to form operational feedback. Specifically, the 3D simulation platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com