A method of activating a lithium ion battery

A lithium-ion battery and battery technology, applied in secondary batteries, secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve problems such as battery safety out of control, functional failure of battery packs, etc., and achieve consistency High, restore battery capacity, reduce the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

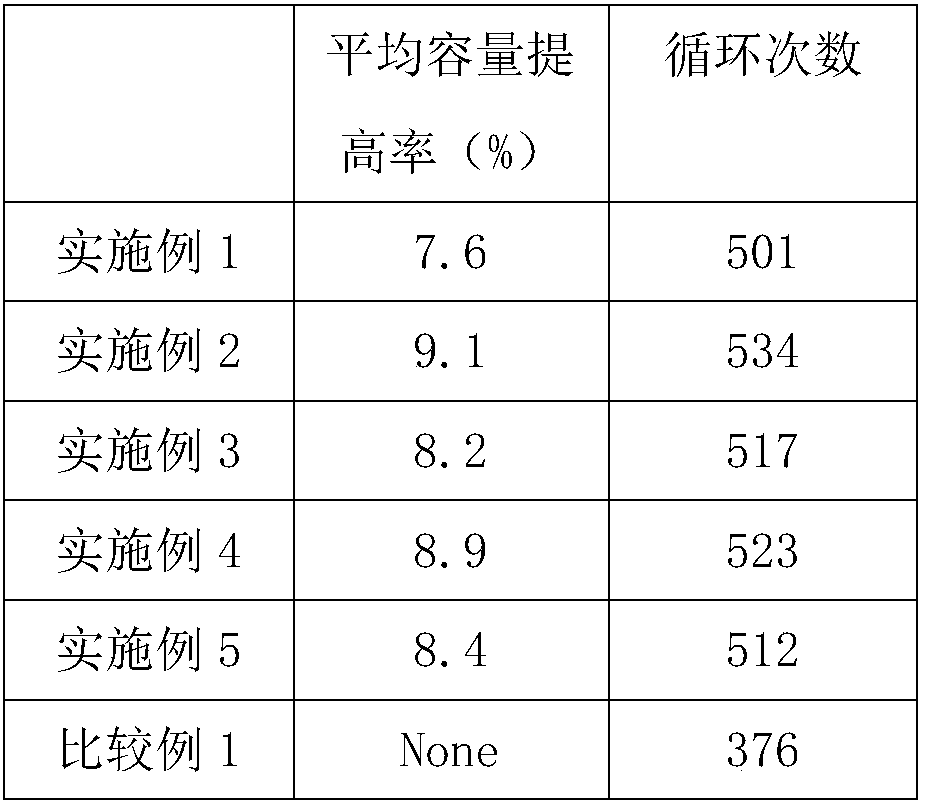

Examples

Embodiment 1

[0027] The operation method of the battery pack, which includes the following screening and activation steps, and continues the power supply work of the battery pack after the activation step:

[0028] 1) Charge the lithium-ion battery in the battery pack to 3.6V at 0.05C;

[0029] 2) Charge to 4.2V at 0.1C;

[0030] 3) Discharge at 1C to 2.7V;

[0031] 4) Measure the temperature of each single battery and calculate the average temperature;

[0032] 5) Take the battery whose temperature is higher than the average value as the battery to be activated, and continue to over-discharge to the over-discharge cut-off voltage:

[0033] Over-discharge cut-off voltage=2.7-0.1*(single battery temperature / average temperature-1);

[0034] 6) Perform positive and negative alternating pulse current cycles on the battery to be activated for 3 times near its voltage, the magnitude of the positive pulse current and the negative pulse current are the same as 0.1C, the pulse action time is the...

Embodiment 2

[0036] The operation method of the battery pack, which includes the following screening and activation steps, and continues the power supply work of the battery pack after the activation step:

[0037] 1) Charge the lithium-ion battery in the battery pack to 3.7V at 0.1C;

[0038] 2) Charge to 4.3V at 0.5C;

[0039] 3) Discharge at 2C to 2.8V;

[0040] 4) Measure the temperature of each single battery and calculate the average temperature;

[0041] 5) Take the battery whose temperature is higher than the average value as the battery to be activated, and continue to over-discharge to the over-discharge cut-off voltage:

[0042] Over-discharge cut-off voltage=2.8-0.8*(single battery temperature / average temperature-1);

[0043] 6) Perform positive and negative alternating pulse current cycles on the battery to be activated for 20 times near its voltage. The magnitude of the positive pulse current and the negative pulse current are the same as 0.2C, and the pulse action time is...

Embodiment 3

[0045] The operation method of the battery pack, which includes the following screening and activation steps, and continues the power supply work of the battery pack after the activation step:

[0046] 1) Charge the lithium-ion battery in the battery pack to 3.6V at 0.08C;

[0047] 2) Charge to 4.2V at 0.2C;

[0048] 3) Discharge at 1.5C to 2.7V;

[0049] 4) Measure the temperature of each single battery and calculate the average temperature;

[0050] 5) Take the battery whose temperature is higher than the average value as the battery to be activated, and continue to over-discharge to the over-discharge cut-off voltage, and the cut-off voltage satisfies the following formula:

[0051] Over-discharge cut-off voltage=2.7-0.5*(single battery temperature / average temperature-1);

[0052] 6) The battery to be activated is subjected to positive and negative alternating pulse current cycles 10 times near its voltage. The magnitude of the positive pulse current and the negative pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com