Flushing device of grille pollution remover

A flushing device and decontamination machine technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of complex structure of flushing equipment, affecting filtration work, inconvenient flushing operation, etc., and achieve flushing uniformity Good, easy to wash operation, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

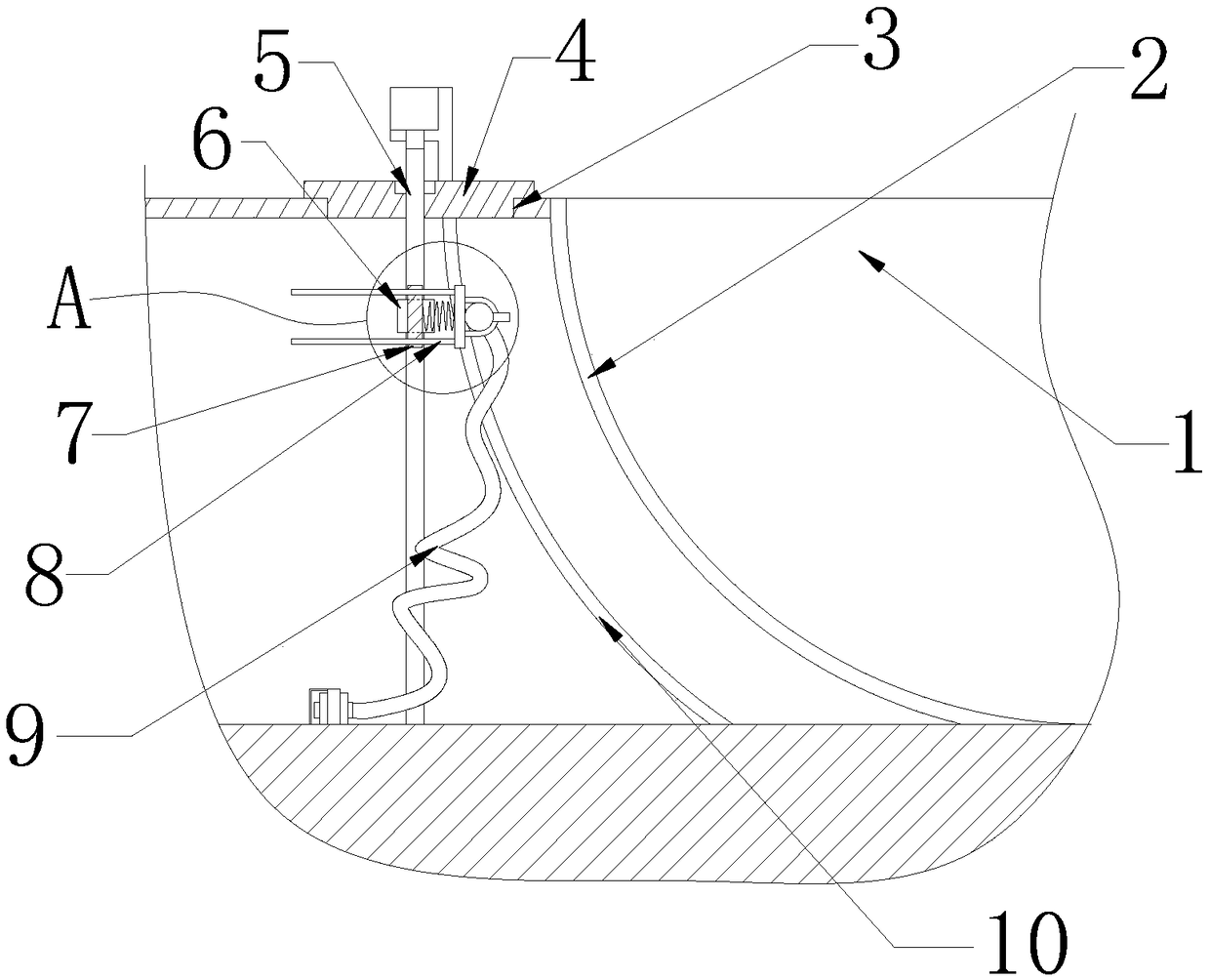

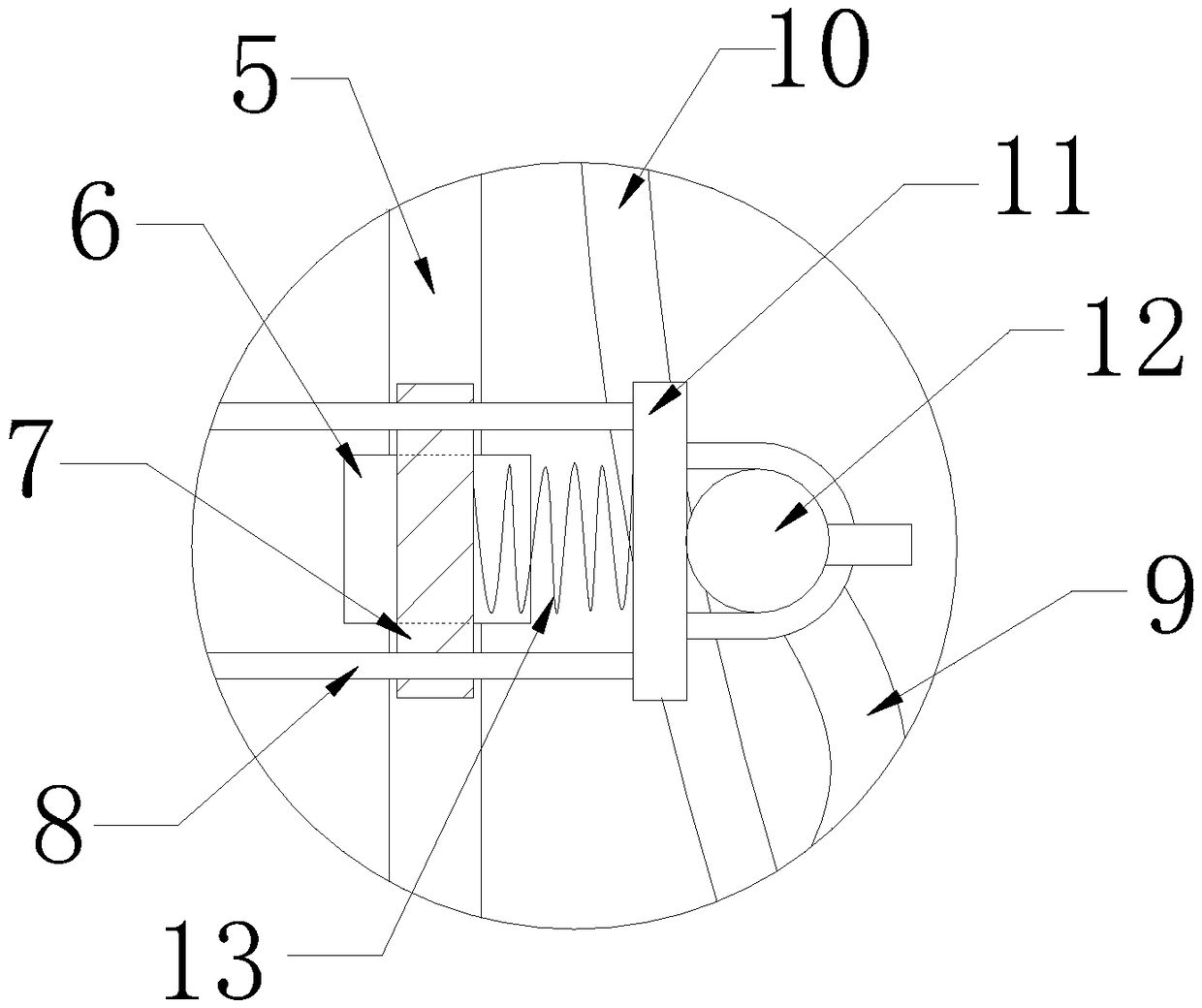

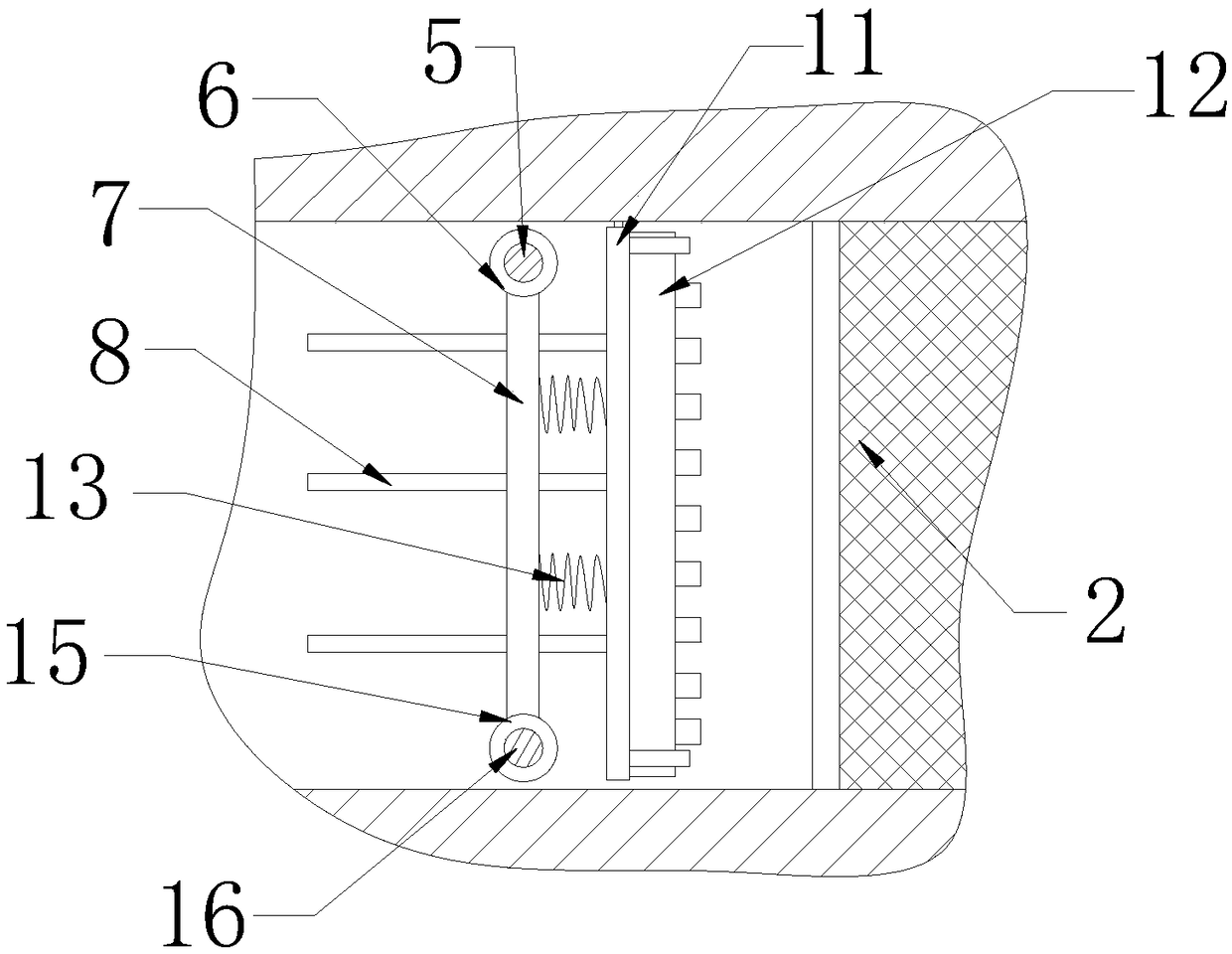

[0017] see Figure 1-Figure 4 , the present invention provides a technical solution: a flushing device for a grid decontamination machine, including a river channel installation port 1, a grille 2 and a flushing assembly, the grille 2 is installed at the left end of the river installation port 1, and the flushing assembly is installed at the grid At the upper end of the river on the left side of the gate 2, the flushing assembly includes an opening 3, a carrier plate 4, a screw rod 5, a ball nut seat 6, a horizontal plate 7, a guide rod 8, a hose 9, an arc-shaped chute 10, a moving plate 11, a hard Tube 12, spring 13, arc-shaped slider 14, moving sleeve 15 and fixed round rod 16, opening 3 is processed on the upper end of the river channel on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com