Mechanical metal pipe reamer

A pipe reamer and mechanical technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problem of reaming of metal pipes of different diameters, etc., to facilitate replacement, improve hole reaming efficiency, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

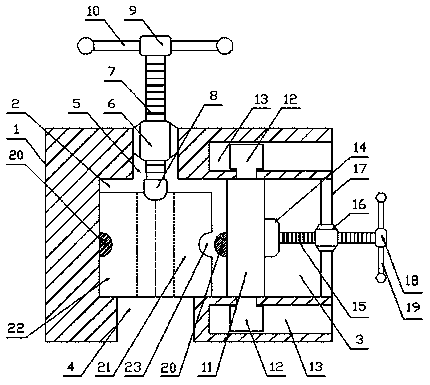

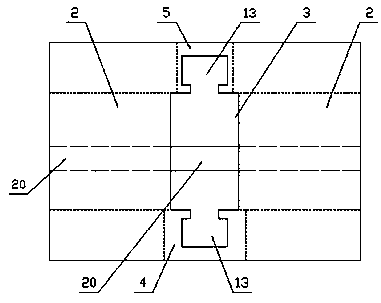

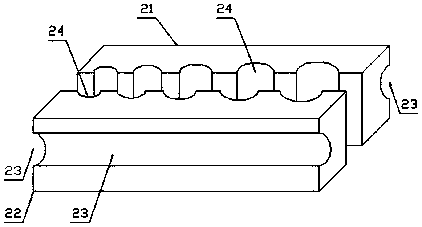

[0027] Such as Figure 1 to Figure 4 As shown, a mechanical metal pipe reamer includes a support base 1, the front of the support base is provided with a through groove 2, and the support base perpendicular to the upper and lower ends of the through groove is respectively provided with an upper through hole 5 and a lower through hole 4 , the upper through hole, the lower through hole communicate with the through groove, the support seat perpendicular to the right end of the through groove is provided with a first receiving groove 3, the first receiving groove communicates with the through groove, and the upper receiving hole is provided with a first nut 6, The first nut is provided with an anastomotic first threaded mandrel 7, the upper end of the first threaded mandrel is connected with the lower surface of the first connecting block 9, the side of the first connecting block is connected with the first handle rod 10, and the lower end of the threaded mandrel is connected with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap