Numerical control flame plasma jig cutting prevention device and use method thereof

A plasma tire and anti-cutting technology, applied in the field of ion tire frame, can solve the problems of high cost of replacing rib or tire frame, high cost of use and maintenance, inconvenient use, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

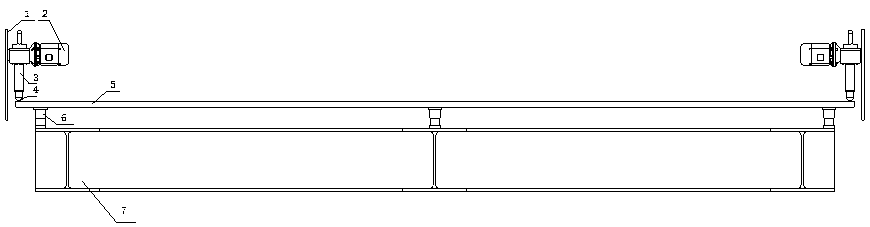

[0021] Attached below figure 1 to attach Figure 4 Discuss the present invention in detail:

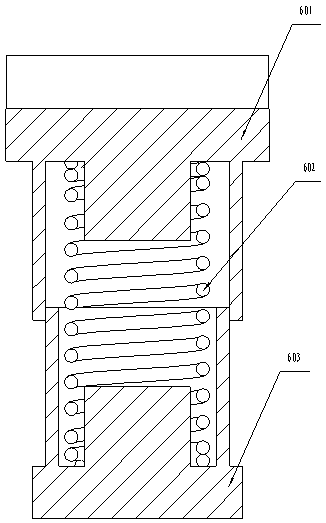

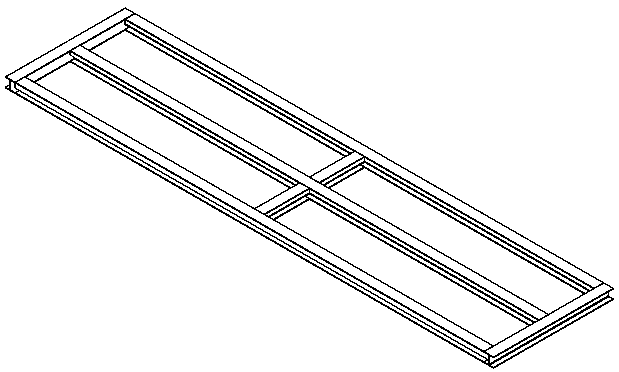

[0022] A CNC flame plasma tire frame anti-cutting device, which is mainly composed of a motor 2, an electric push rod 3, a tire frame rib 5, a telescopic sleeve mechanism 6, and a tire frame body 7; The motor 2 is symmetrically installed on the inner side of the leg 1. The motor 2 is connected to the electric push rod 3. The left and right sets of electric push rods 3 are on the same axis as the torch. The bottom of the electric push rod 3 is provided with a hemispherical joint 4. 4 is in contact with the upper surface of the tire frame rib 5, and multiple sets of telescopic sleeve mechanisms 6 are installed on the bottom of the tire frame rib 5, and the telescopic sleeve mechanisms 6 are uniformly welded on the tire frame body 7, and the tire frame body 7 is composed of a frame structure Composition, each set of tire frame ribs 5 uses three sets of telescopic sleeve mechanisms 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com