Full automatic multi-map puncher system used for book page die punching

A fully automatic, book-page technology, applied in metal processing, transportation and packaging, conveyor objects, etc., can solve the problems of high production manpower demand, low production efficiency of punching presses, high labor intensity, etc., to eliminate hidden dangers of production safety and improve punching The effect of cutting production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

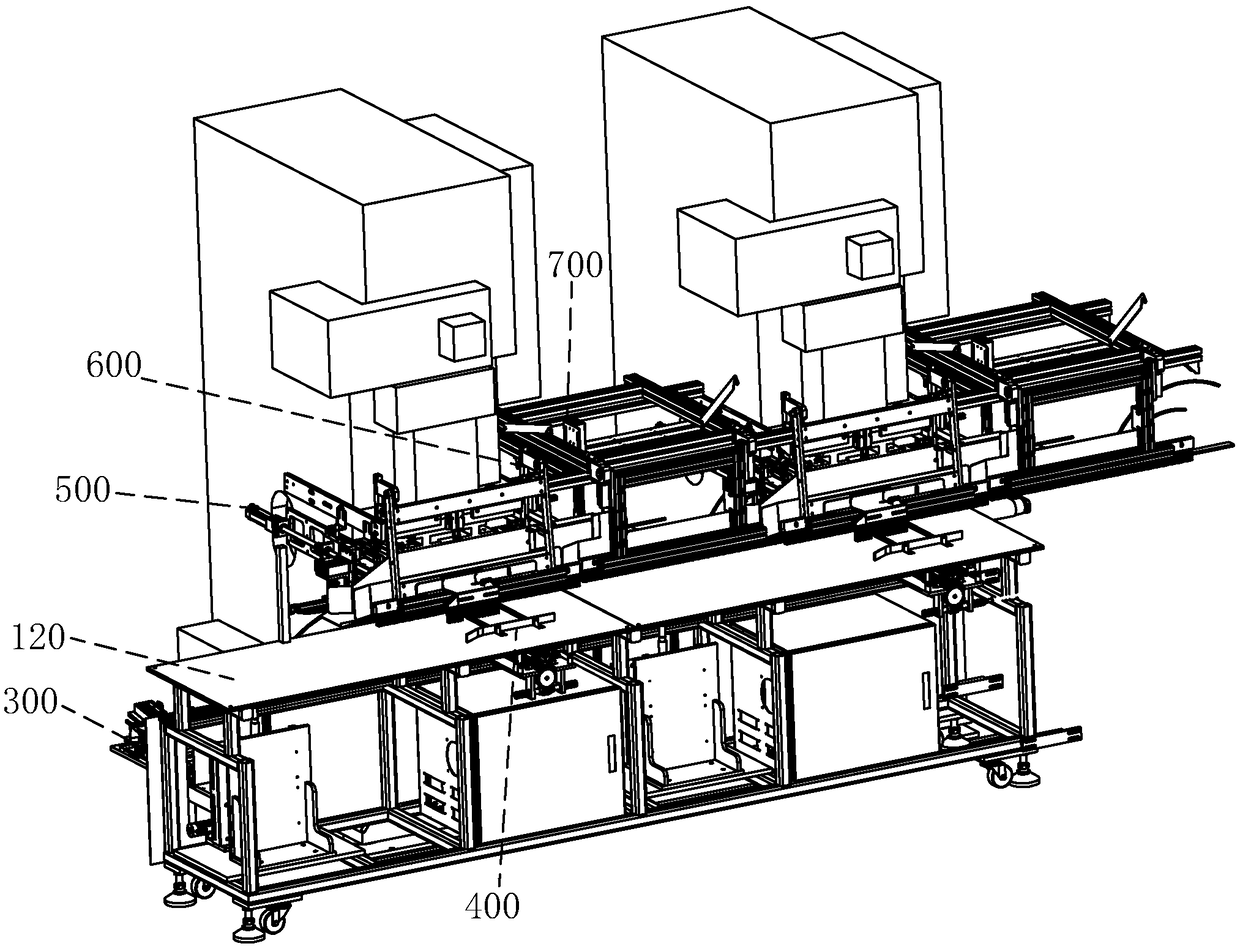

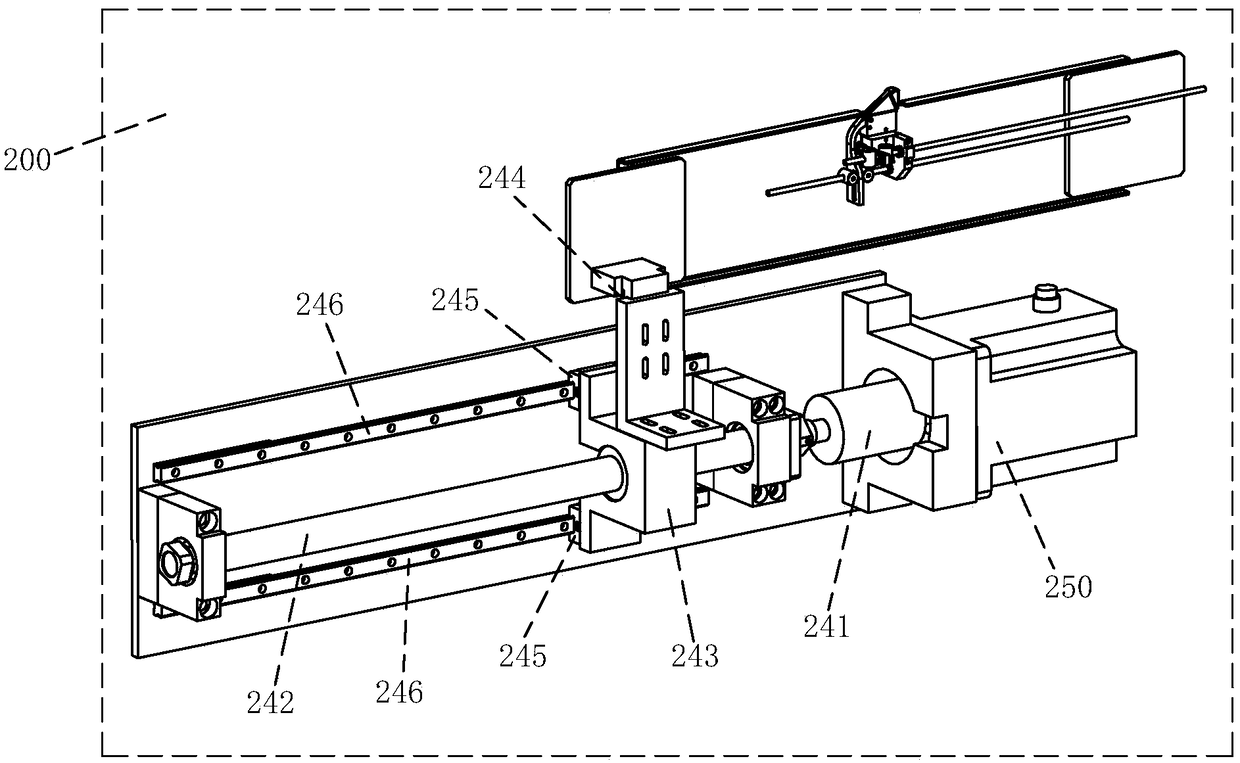

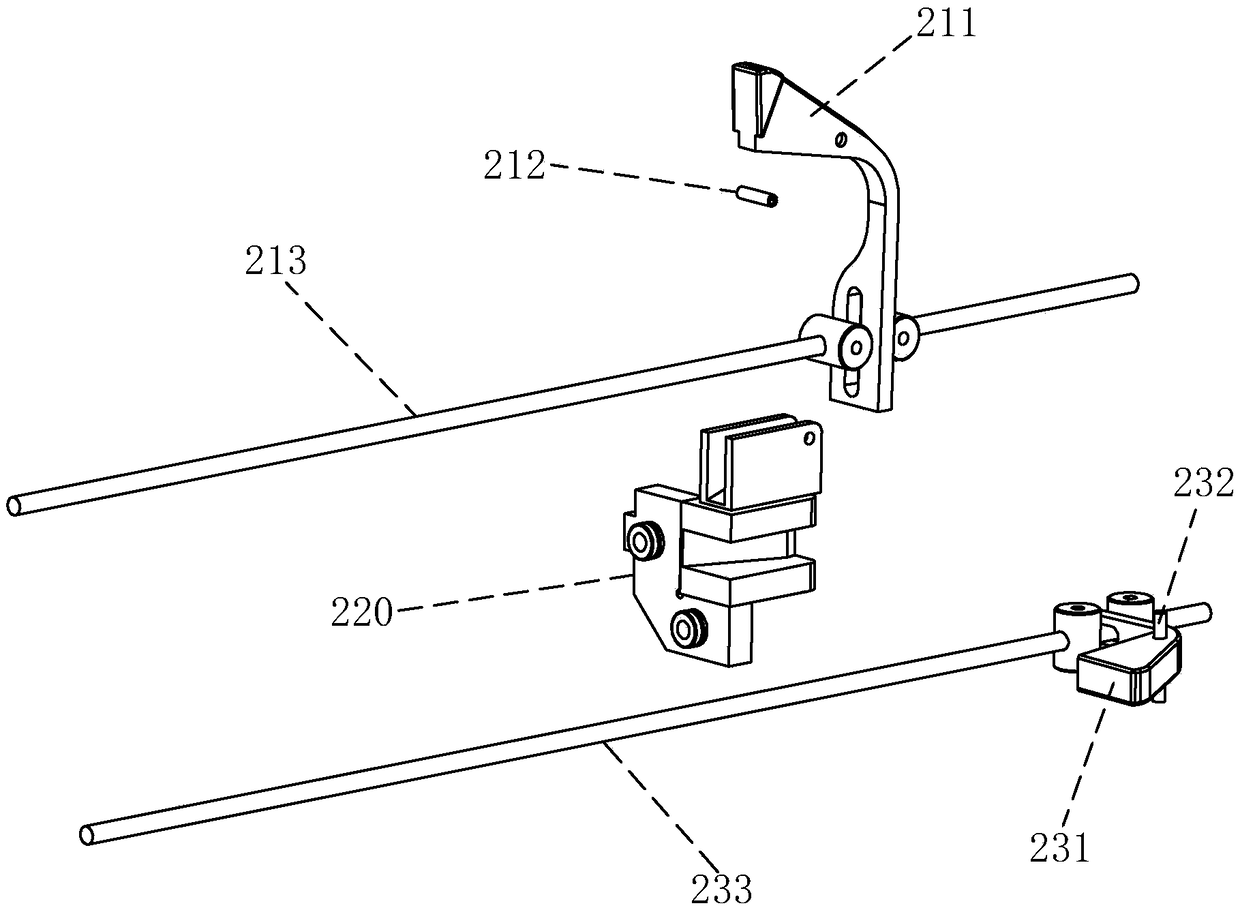

[0032] refer to figure 1 - Figure 14 , a kind of full-automatic multi-stick punch system for punching book pages of the present invention includes a conveying platform 120, a stamping table 110, an automatic pusher device 200 for pushing books and an automatic page turning device for turning pages of books The device 300, the stamping table 110 and the automatic page turning device 300 are all arranged on the same side of the conveying platform 120, and there is a placement slot 130 for placing books between the stamping table 110, the automatic page turning device 300 and the conveying platform 120 , the automatic hand pushing device 200 is set on the conveying platform 120 .

[0033] The present invention can embed multi-posted book cards in the placement slot 130, then transport the books on the transport platform 120 through the automatic pusher device 200, and transport them to the stamping table 110, and also pass the automatic page turning device during the transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com