Reinforcing steel sheet punching die and machining process thereof

A technology for punching dies and reinforcing steel sheets, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of low qualified rate of steel sheets and damage of steel sheets, and achieve simple and convenient operation and reduce work intensity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

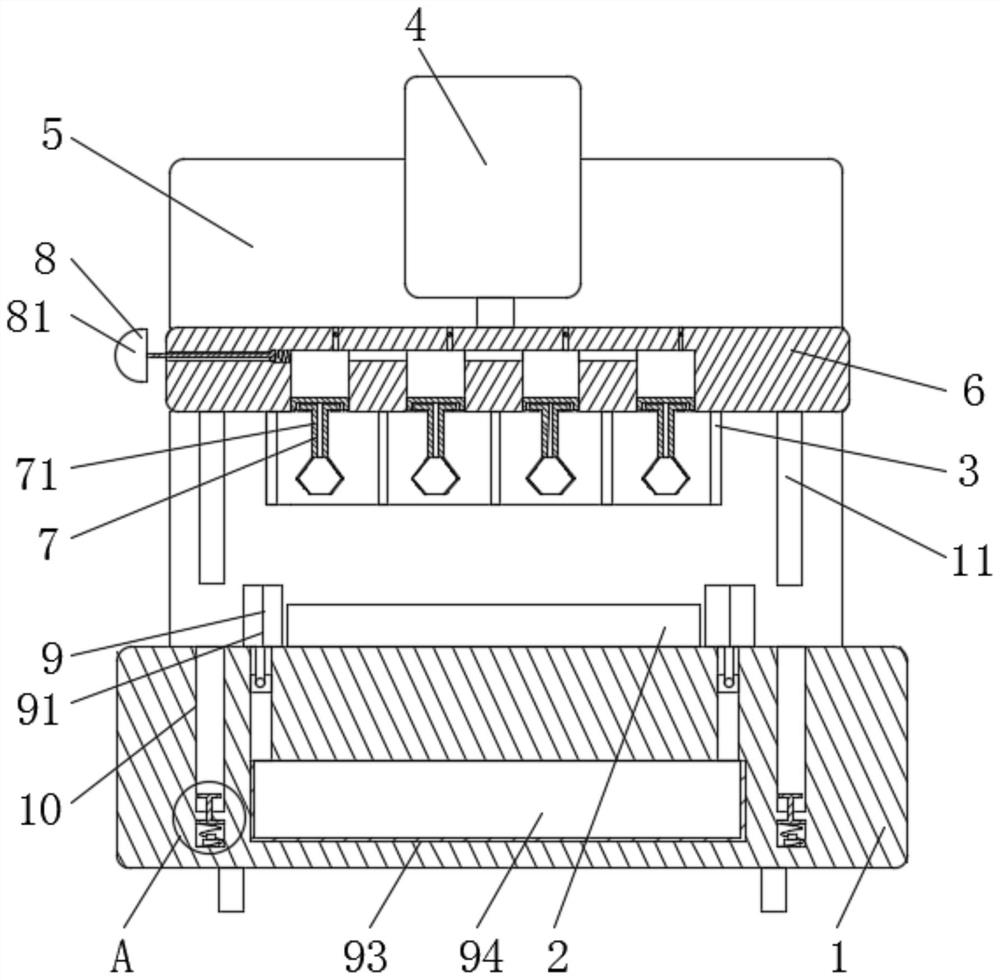

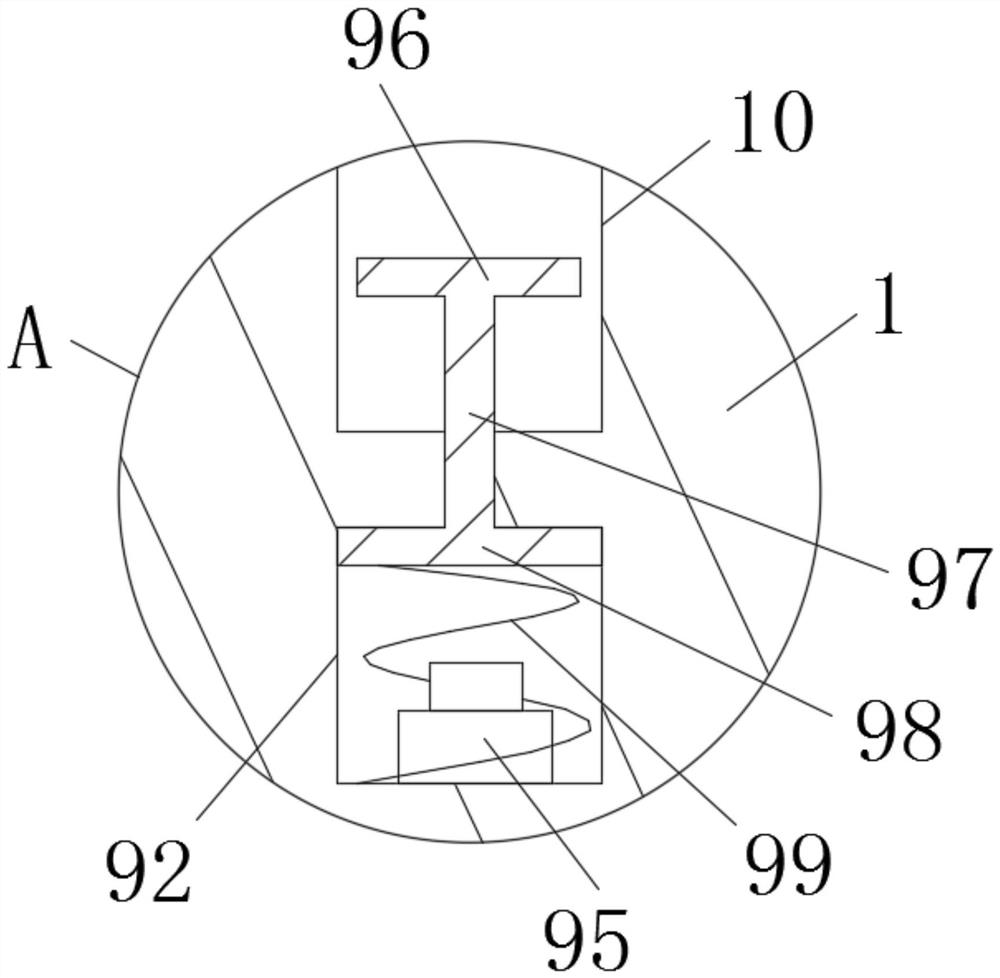

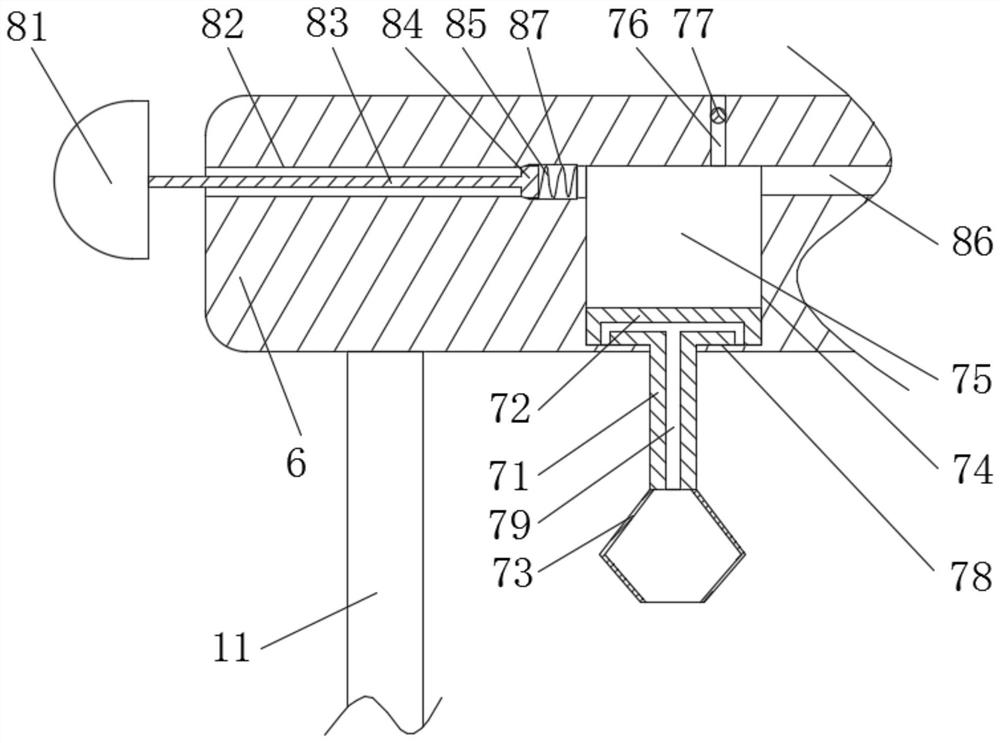

[0031] see Figure 1-6 , the present invention provides a technical solution: a reinforced steel sheet punching die, including a console 1, a support frame 5 is fixed on the top of the console 1, a hydraulic cylinder 4 is fixed on one side of the support frame 5, and a push rod of the hydraulic cylinder 4 A movable mold 6 is fixed at the end of the movable mold 6, and several punching knives 3 are fixed on the bottom of the movable mold 6. The bottom of the punching knives 3 is fitted with a fixed mold 2 fixed on the top of the console 1. The top of the fixed mold 2 is provided with an adsorption assembly 7, which absorbs One side of the component 7 is provided with a reset component 8, and one side of the reset component 8 is provided with a cleaning component 9. The push rod end of the hydraulic cylinder 4 pushes the movable mold 6 and the punching tool 3 to move to the fixed mold 2 side, and cleans the steel sheet. Punching, and multiple steel sheets can be punched at one t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com