Lightweight block cutting replacement device

A block and lightweight technology, which is applied in the field of lightweight block cutting mechanism, can solve the problems that the contact surface is prone to sag and affect the surface quality of finished blocks, so as to prevent surface sag, strong water absorption, and improve surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

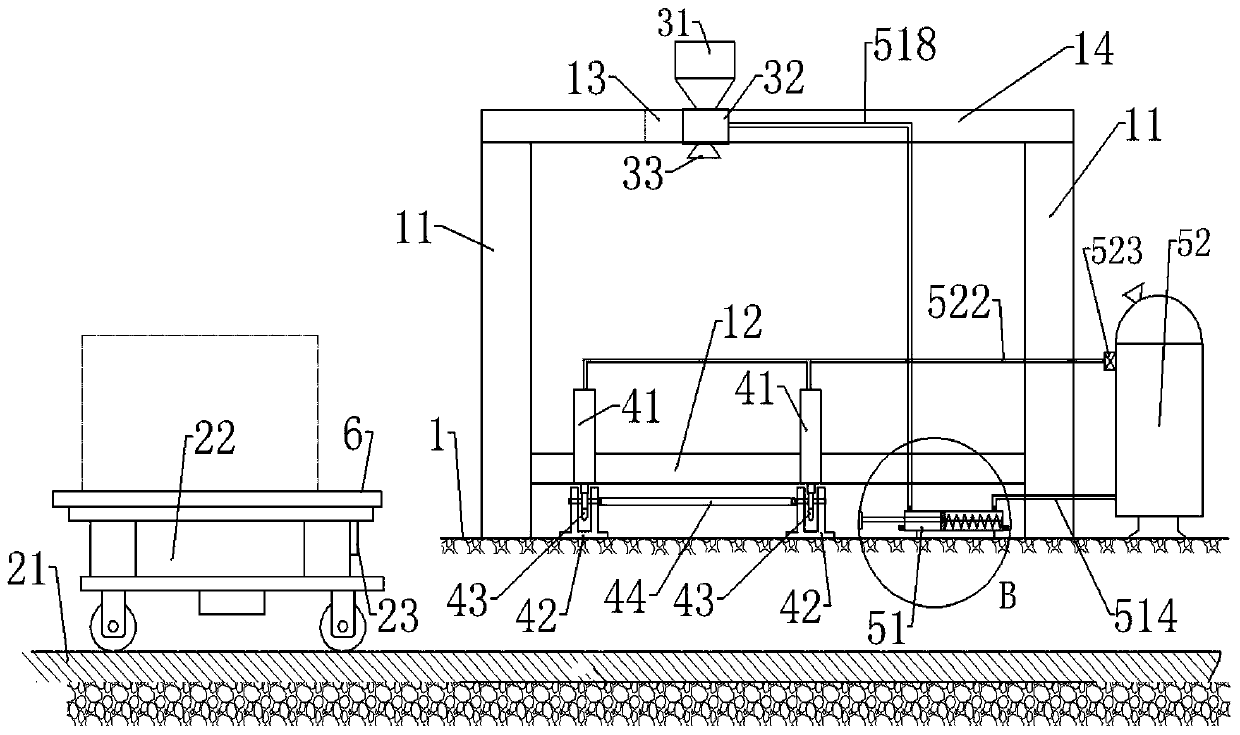

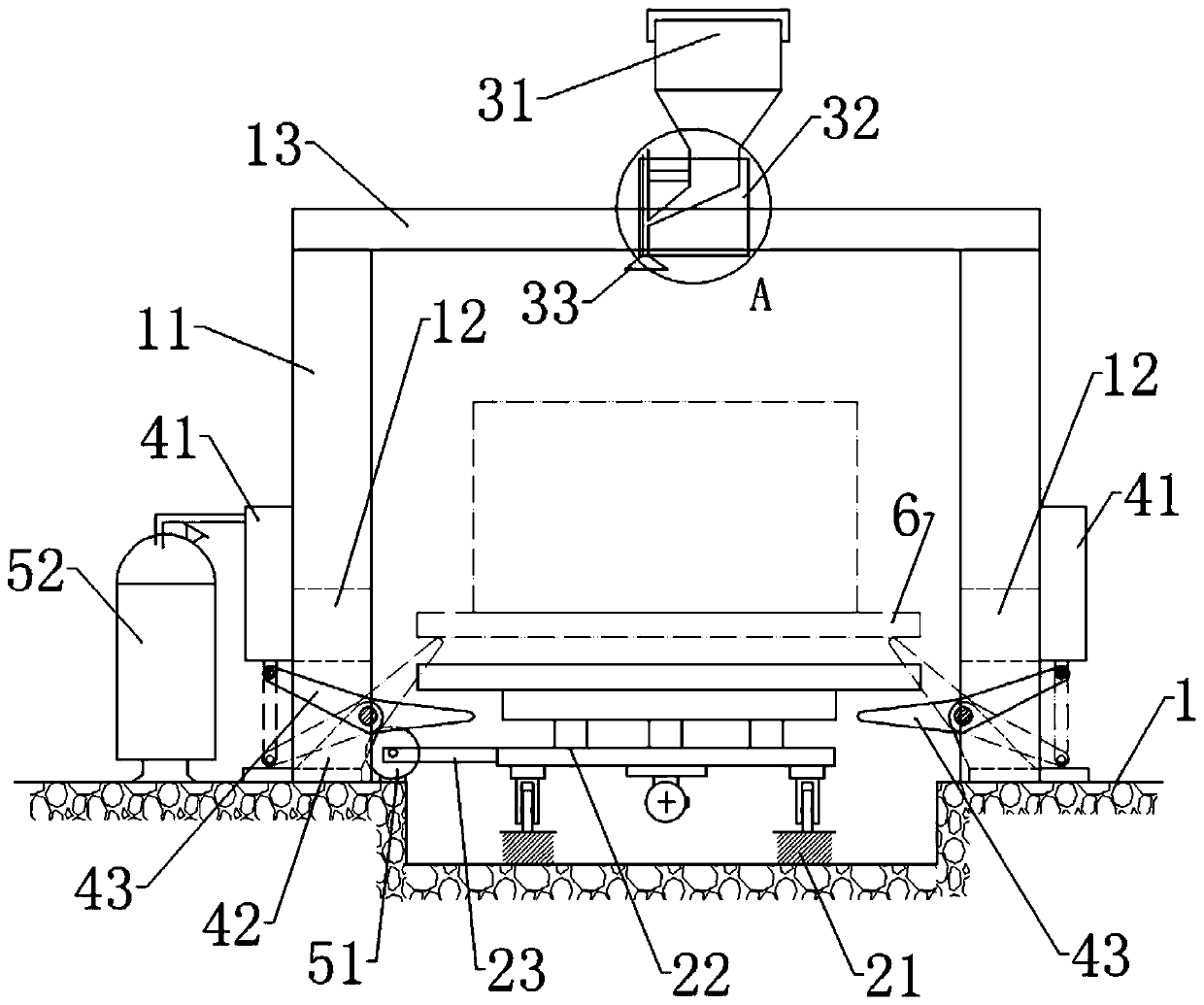

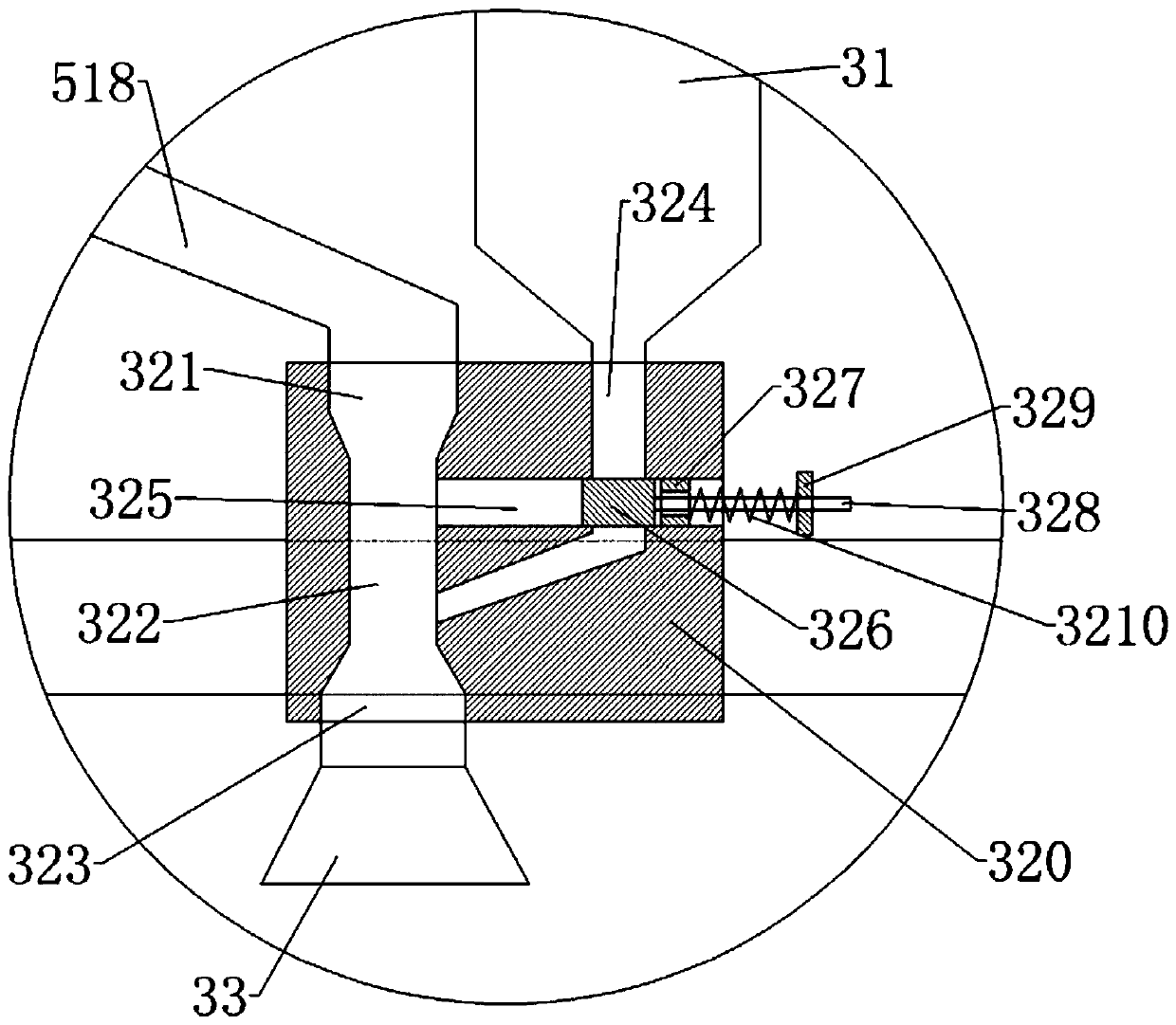

[0021] The reference signs in the accompanying drawings of the description include: abutment 1, column 11, lower beam 12, longitudinal beam 13, upper beam 14, track 21, transport vehicle 22, push plate 23, feed box 31, discharge valve 32, Valve seat 320, inlet channel 321, throat channel 322, diffuser channel 323, discharge channel 324, slideway 325, valve core 326, limit block 327, connecting rod 328, adjustment block 329, compression spring one 3210, nozzle 33, Cylinder 41, support seat 42, support arm 43, synchronous shaft 44, air cylinder 51, cylinder body 510, piston 511, piston rod 512, compression spring 2 513, air pipe 1 514, check valve 1 515, air inlet 1 516 , check valve two 517, air pipe two 518, check valve three 519, air inlet two 5110, check valve four 5111, gas storage tank 52, air pipe three 522, air valve 523, supporting plate 6.

[0022] The embodiment is basicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com